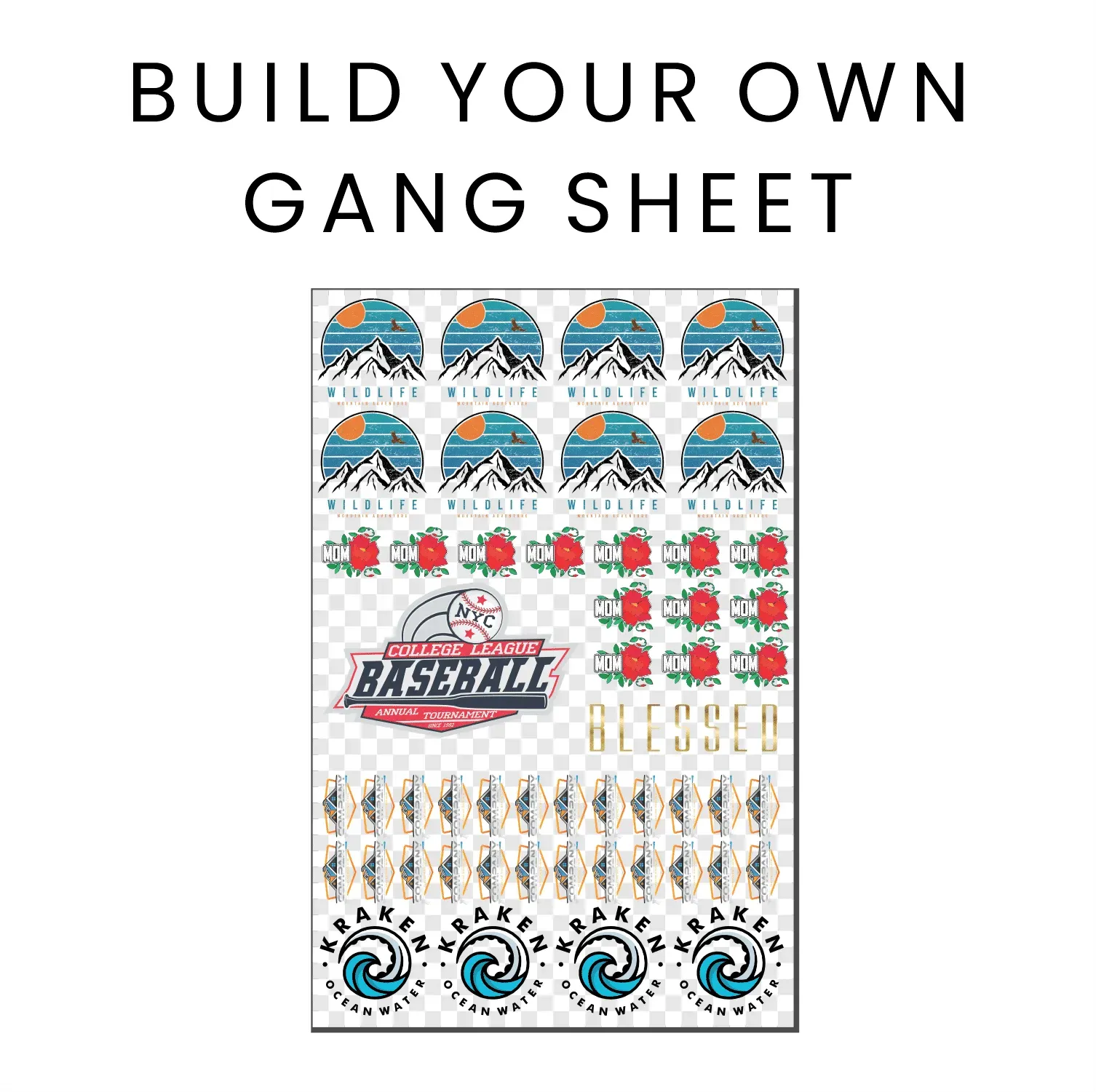

In the world of printing technology, the DTF Gangsheet Builder is a game-changer that offers innovative solutions for businesses looking to elevate their printing processes. This advanced method leverages Direct to Film (DTF) printing advantages, providing seamless printing capabilities that rival traditional printing methods such as screen printing and direct-to-garment (DTG). By enabling multiple designs to be processed on a single film, the DTF Gangsheet Builder optimizes material usage, making it a cost-effective printing solution for both small and large runs. As we explore the benefits of this technology, it becomes clear how it outshines conventional methods in terms of efficiency, quality, and setup flexibility. Join us as we delve into why the DTF Gangsheet Builder could be the ultimate choice for modern businesses.

The DTF Gangsheet Builder represents a significant leap in printing techniques, streamlining the process for those in need of high-quality output with minimal waste. Often referred to as innovative film printing technology, this method strongly contrasts with older practices like screen printing and direct-to-garment (DTG) approaches. The growing preference for cost-efficient alternatives has sparked interest in tools that enhance production while maintaining quality, leading to the rise of DTF solutions. Understanding the nuances between these printing methodologies, including their environmental impacts, production efficiency, and versatility, is essential for any business aiming to succeed in today’s competitive landscape. Therefore, let’s dissect how the DTF Gangsheet Builder meets the evolving demands of the market.

The Advantages of DTF Printing Over Traditional Methods

DTF printing brings a multitude of advantages that significantly enhance the productivity of modern printing businesses. One of the primary benefits is the reduced initial setup time. Thanks to the DTF Gangsheet Builder, multiple designs can be printed on a single sheet, allowing businesses to fulfill diverse orders without the lengthy setup associated with traditional methods like screen printing. This capability not only saves time but also minimizes the waste of materials, making DTF particularly advantageous in today’s eco-conscious market.

In addition to speed, DTF printing excels in terms of quality and design versatility. It allows for vibrant colors and intricate details that can elevate the final product, surpassing many traditional methods. Unlike screen printing, which can struggle with complex designs, DTF maintains high fidelity across various fabric types. Thus, businesses can cater to a wider range of customer demands, reinforcing the cost-effectiveness strategy where high-quality products can command better prices in the market.

Cost-Effectiveness of DTF Gangsheet Builder

When comparing DTF printing to traditional methods, one cannot overlook the cost-effectiveness that the DTF Gangsheet Builder offers. For small to medium-sized businesses, this technology becomes a financial game-changer. Lower setup costs and reduced ink consumption mean that even smaller runs become viable economically. In contrast, traditional screen printing frequently demands higher initial investments due to the setup needed for each design, which can deter businesses from experimenting with diverse offerings.

Moreover, the scalability of DTF printing allows for a more strategic allocation of resources. As production needs fluctuate, businesses can easily adjust their output without incurring significant extra costs. This adaptability makes the DTF Gangsheet Builder a compelling option for companies looking to maximize their return on investment while minimizing wasteful expenditures.

Environmental Benefits of DTF Printing

In an age where sustainability is paramount, the environmental merits of DTF printing cannot be understated. The DTF Gangsheet Builder utilizes eco-friendly inks and materials that significantly reduce the ecological footprint compared to traditional printing methods, which often rely on petroleum-based inks that contain hazardous chemicals. By choosing DTF technology, companies demonstrate their commitment to sustainable practices, aligning with the values of modern consumers who prioritize eco-awareness.

Moreover, the reduction of material waste inherent in DTF printing adds to its green profile. Traditional methods like screen printing generate excess screens and inks that typically end up discarded. DTF’s capability to print multiple designs on a single sheet not only conserves resources but also supports businesses in enhancing their sustainability credentials—a significant factor in today’s competitive landscape.

Setup Flexibility in DTF Gangsheet Printing

The adaptability of the DTF Gangsheet Builder sets it apart from traditional printing methods. Unlike screen printing, which can often be restricted by the type of material or color of fabric, DTF printing can handle a wide range of fabrics, including dark materials and specialty textiles. This flexibility enables businesses to expand their offerings without needing separate equipment for different substrates, creating a streamlined operation that aligns with modern business demands.

Furthermore, DTF’s ability to work on non-textile surfaces such as plastics and metals opens up new markets for printers willing to explore diversification. This capability empowers businesses to broaden their service portfolios, making DTF a valuable asset in a changing landscape where customer needs are increasingly specialized.

Quality Comparison: DTF vs. Traditional Methods

When it comes to quality, DTF printing has proven itself as a superior option for high-resolution work. The advanced ink technology used in DTF assures that colors remain vibrant and designs are sharp, regardless of the fabric. This stands in stark contrast to traditional screen printing, which while excellent for bold, simple designs, can often lead to unsatisfactory results with more intricate or multi-colored images.

Moreover, durability is a crucial factor in print quality. DTF prints adhere closely to fabric fibers, enhancing wash and wear resistance, which means products maintain their appearance longer. This durability factor is essential for businesses focused on customer satisfaction and repeat business, with many customers valuing longevity in their purchases.

The Role of DTF in Modern Printing Businesses

As the printing industry continues to evolve, the integration of DTF technology reflects a significant shift towards more responsive, less wasteful practices. The DTF Gangsheet Builder is not just a novel tool but represents a movement toward efficiency, quality, and sustainability in printing operations. This modern solution meets the needs of 21st-century consumers who demand faster service while emphasizing environmental responsibilities.

Investing in DTF printing technology allows businesses to position themselves as forward-thinking innovators in their field. As they adapt to consumer trends favoring customization, speed, and environmental consciousness, companies utilizing DTF will likely outperform those relying solely on traditional printing methods, securing their place in a competitive market.

Frequently Asked Questions

What are the main advantages of using the DTF Gangsheet Builder over traditional printing methods?

The DTF Gangsheet Builder offers significant advantages such as faster production rates and quicker turnaround times. It allows businesses to print multiple designs on a single film, resulting in efficient material usage and reduced waste. Additionally, DTF printing is cost-effective for small to medium runs, compared to traditional methods like screen printing that have high setup costs.

How does DTF printing compare in quality to screen printing and direct-to-garment (DTG) methods?

DTF printing excels in delivering vibrant colors and intricate designs, making it ideal for businesses that prioritize detail and quality. While screen printing offers great longevity for simple designs, it may struggle with complex patterns. DTG can achieve good results but is often limited by fabric type, whereas DTF adapts more easily across various materials.

Is the DTF Gangsheet Builder environmentally friendly compared to traditional printing methods?

Yes, the DTF Gangsheet Builder can be more environmentally friendly due to the use of advanced, water-based eco-friendly inks that reduce harmful emissions. This contrasts with some traditional methods that rely on chemical-rich inks, raising sustainability concerns. As businesses move towards green practices, DTF aligns better with eco-conscious goals.

What is the setup process like for the DTF Gangsheet Builder compared to screen printing or DTG?

The DTF Gangsheet Builder has a more efficient setup process, allowing for printing on various materials without extensive pretreatment, unlike DTG which requires additional steps for dark fabrics. Screen printing involves a labor-intensive setup for each design, making DTF a more flexible option for diverse printing needs.

Can the DTF Gangsheet Builder handle different fabric types and substrates effectively?

Absolutely! The DTF Gangsheet Builder is versatile and capable of printing on various fabric types, including dark materials, and can extend beyond textiles to plastics and metals. This adaptability makes it a suitable choice for businesses looking to offer diverse products without additional equipment investments.

What factors should a business consider when choosing between DTF printing and traditional methods like screen printing?

Businesses should evaluate their production volume, required print quality, design complexity, and budget when choosing between DTF printing and traditional methods. For smaller runs with detailed designs, DTF printing is usually more cost-effective and efficient, while screen printing may be advantageous for larger orders due to lower per-item costs.

| Criteria | DTF Gangsheet Builder | Traditional Printing Methods |

|---|---|---|

| Efficiency and Speed | High efficiency; faster production rates and quick turnaround. | Slower, especially for complex designs; lengthy setup processes for each design. |

| Quality and Detail | Delivers vibrant colors and intricate designs with durability. | Great for simple designs; might struggle with complexity and durability in some cases. |

| Cost-Effectiveness | More cost-effective for small to medium runs with lower setup costs. | Cost-effective at a large scale, but higher setup costs for smaller batches. |

| Setup and Material Flexibility | Can print on various materials; high adaptability without extensive investment. | Less flexible; requires special treatment for different fabrics, especially DTG. |

| Environmental Impact | Uses eco-friendly inks; aligns better with sustainability effort. | Often relies on chemical inks, leading to potential environmental concerns. |

Summary

DTF Gangsheet Builder represents a cutting-edge advancement in printing technology that caters to diverse business needs. This modern approach not only enhances efficiency and quality but also offers significant cost savings and flexibility compared to traditional methods. With its ability to print intricate designs on various materials and its focus on environmentally-friendly practices, the DTF Gangsheet Builder stands out as a powerful tool for any company looking to innovate in the custom printing landscape. As the industry continues to evolve, understanding these advancements will be crucial for businesses aiming to stay competitive in a dynamic market.