In the realm of custom apparel printing, DTF Transfers—short for Direct-to-Film Transfers—are redefining how we produce vibrant and intricate designs on fabric. This innovative technique not only delivers high-quality images that stand out with rich colors but also caters to the growing demand for sustainable printing solutions. Unlike traditional methods, the DTF printing process minimizes waste, making it a preferable choice for both eco-conscious brands and creative individuals. As DTF transfers gain popularity, they offer unparalleled versatility for a wide range of fabric types, enabling users to elevate their fashion creations effortlessly. Join us as we explore the myriad benefits and practical applications that DTF transfers bring to the world of textile printing.

Also known as Direct-to-Film printing, DTF Transfers have captivated the custom apparel industry with their cutting-edge technology and impressive capabilities. This modern approach to fabric printing allows for the seamless application of intricate designs, making it a viable option not just for professionals, but also for enthusiastic hobbyists. By employing a unique process that prints designs on a special film, this method not only ensures vivid colors and sharp details but also aligns with the principles of sustainable printing by reducing waste. The adaptability of DTF technology extends to various textile types, making it a game-changer for anyone looking to create custom apparel that reflects both quality and eco-friendliness. As we delve deeper into the world of DTF printing, you’ll discover the essential knowledge and tips needed to harness this extraordinary technology.

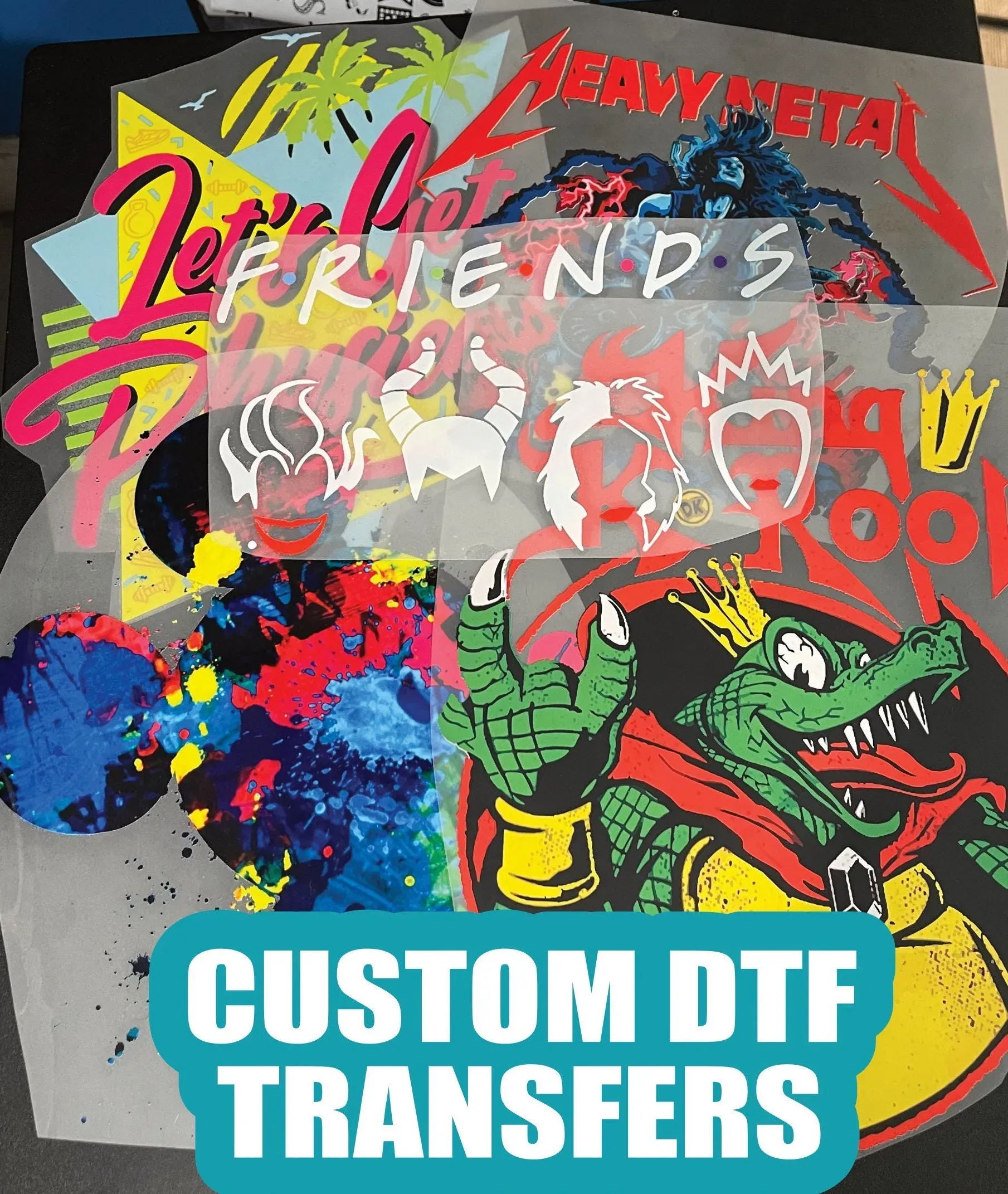

The Basics of DTF Printing

DTF printing, or Direct-to-Film printing, is a relatively new technique that offers a vibrant and efficient way of creating intricate designs on fabric. This method involves printing designs onto a specialized film that can be transferred onto various materials. Unlike traditional print methods, DTF allows for exceptional detail and color density, making it a favorite among designers and custom apparel manufacturers. The process begins with printing the design on a transfer film and applying an adhesive powder that is fused into the film under heat. This ensures that when the film is applied to the fabric, the design adheres strongly, providing durability and longevity.

One of the critical factors that set DTF printing apart is its compatibility with a wide variety of fabrics, including cotton and polyester blends, which are commonly used in apparel production. This versatility means that DTF transfers can cater to diverse printing needs, whether for personal projects or commercial apparel lines. As DTF technology continues to evolve, consumers and business owners alike are discovering the benefits of using this innovative method in their printing endeavors, ensuring a product that not only looks great but stands the test of time.

Advantages of Using DTF Transfers

Choosing DTF transfers for custom apparel printing comes with a multitude of benefits that make it a top choice for businesses and hobbyists. One significant advantage is the vividness and clarity of the prints. DTF technology produces sharp, high-resolution designs with an appealing brightness that is hard to replicate using other methods. Whether it’s an intricate logo or a detailed graphic, DTF transfers are capable of capturing all the nuances of the design, offering an aesthetically pleasing final product that attracts customers.

Moreover, the durability of DTF prints stands out when compared to traditional methods. Research has shown that DTF transfers hold up well even after numerous washes, maintaining their color and grip on the fabric. This resilience reduces the likelihood of wear and tear, ensuring that customers receive quality apparel that lasts. As a result, businesses can enjoy increased customer satisfaction and repeat purchases while keeping production costs low due to fewer reprints and returns.

Sustainability in DTF Printing

Sustainability is a critical concern in today’s printing industry, and DTF printing is paving the way for eco-friendly practices. Unlike conventional printing techniques, DTF transfers produce significantly less waste while maintaining high-quality outputs. For instances, the ability to print multiple designs on a single film reduces material usage and environmental impact. This aspect of DTF technology not only supports businesses in meeting their sustainability goals but also attracts a growing customer base that values eco-conscious practices in their purchases.

Additionally, the inks and materials used in the DTF printing process are often chosen with sustainability in mind. Many manufacturers are transitioning to water-based inks, which have a lower environmental impact than solvent-based alternatives. By choosing DTF printing, businesses can position themselves as responsible leaders in the apparel market, appealing not only to the environmentally conscious consumer but also reinforcing their commitment to sustainable growth and operational practices.

Recent Innovations in DTF Technology

The DTF printing industry is rapidly evolving, with new innovations continually enhancing its efficiency and accessibility. For example, the introduction of advanced web-to-print platforms has revolutionized how businesses order and manage DTF transfers. Services like Snuggle’s Trade DTF Service cater specifically to the needs of commercial clients, allowing them to access high-quality prints in significant volumes. This is particularly beneficial for apparel companies looking to streamline their production processes and respond swiftly to market demands.

Furthermore, technological advancements in DTF printers and supplies are improving the quality and speed of the printing process. Newer models of printers are capable of producing sharper images faster than ever before. As more businesses invest in high-performance DTF equipment, they can expect to meet higher volumes of orders while ensuring that quality remains uncompromised. The combination of expanded services and cutting-edge technology fosters an environment ripe for creativity and innovation in custom apparel design.

Getting Started with DTF Transfers: A Beginner’s Guide

If you’re new to DTF printing and eager to get started, it’s essential to understand the foundational steps involved in the process. Begin by sourcing quality films and equipment, as these will greatly impact your results. When choosing transfer films, opt for reputable brands that specialize in DTF supplies. After you gather your materials, familiarize yourself with the printing process which includes designing your artwork, printing it onto the film, applying the adhesive, and finally, heat-pressing onto your fabric of choice.

Moreover, testing your techniques on fabric scraps can not only help you fine-tune your settings but also build your confidence as you acclimate to the DTF printing method. Understanding each stage of the process prepares you for common challenges, and learning how to adjust temperatures and pressure settings can ensure successful transfers every time. Armed with this knowledge, any aspiring printer can dive into the world of DTF with excitement and a solid starting foundation.

Maximizing Success with DTF Transfer Applications

Successful application of DTF transfers relies on understanding several key techniques and best practices. Pre-heating the fabric before applying the transfer can significantly enhance adhesion and reduce the risk of peeling. By ensuring the fabric is free of moisture and at the appropriate temperature, you set a strong foundation for a flawless transfer. Another crucial tip is to maintain consistent pressure and temperature during the heat-pressing process to achieve optimal results.

Furthermore, regular maintenance of your DTF printing equipment is vital to ensure consistent output quality. Cleaning print heads, checking ink levels, and ensuring that your printer settings are optimized for the types of films you’re using can greatly improve overall performance. As you gain experience, you may modify these techniques to suit your specific fabric types and designs, allowing you to perfect your DTF transfer application for any project you undertake.

Frequently Asked Questions

What are DTF Transfers and how do they work?

DTF Transfers, or Direct-to-Film transfers, are a method of custom apparel printing that involves printing a design onto a special film, which is then heat-pressed onto fabric. This process allows for vibrant, detailed images to be printed on various materials, making it a versatile option for producing custom clothing.

What makes DTF printing a sustainable choice for custom apparel?

DTF printing is considered a sustainable option in custom apparel printing due to its reduced waste compared to traditional methods. DTF transfers utilize fewer resources while producing high-quality results, which aligns with the increasing demand for eco-friendly practices in the fashion industry.

Can DTF Transfers be used on any type of fabric?

Yes, DTF Transfers can be applied to a wide variety of fabrics, including cotton, polyester, and blends. This versatility allows businesses to create custom apparel that meets diverse customer needs and preferences.

What steps are involved in the DTF printing process?

The DTF printing process involves several steps: first, print your design onto the DTF transfer film using a specialized printer; next, apply a powder adhesive to the printed area; then, heat it to bond with the film; apply the film to the fabric using a heat press, and finally, peel away the film to reveal your design.

Are DTF Transfers durable and long-lasting?

DTF Transfers offer exceptional durability; studies have shown that they can withstand multiple washes without losing color or quality. This makes them an excellent choice for custom apparel that needs to endure everyday wear and washing.

How can businesses benefit from using DTF printing technology?

Businesses can benefit from DTF printing technology by leveraging its cost-effectiveness, high-quality outputs, and versatility. With the ability to produce intricate designs on various fabrics quickly, companies can meet client demands efficiently, appealing to a growing market for custom printed apparel.

| Key Point | Description |

|---|---|

| What are DTF Transfers? | DTF (Direct-to-Film) Transfers are a technology for printing vibrant designs on fabrics using heat-pressing methods. |

| Benefits of DTF Transfers | 1. **Vibrancy and Detail**: Produces sharp images suitable for detailed graphics. 2. **Versatility**: Works on various fabrics like cotton and polyester. 3. **Sustainability**: Reduces waste, aligning with eco-friendly goals. |

| Recent Developments | 1. **Sustainability Initiatives**: Reduces production waste while ensuring quality. 2. **New Services**: Snuggle’s Trade DTF service caters to commercial print needs. 3. **Web-to-Print Innovations**: Simplifies ordering processes for custom prints. |

| Getting Started | 1. **Quality Films**: Invest in high-quality transfer films. 2. **Process Understanding**: Follow specific steps to print, apply adhesives, heat-press and peel. 3. **Durability Testing**: DTF transfers are durable and can be removed without damage to fabric. |

Summary

DTF Transfers are revolutionizing the custom apparel printing landscape by offering high-quality, vibrant designs that can be applied to a variety of fabrics. Their efficiency and ability to minimize waste align with modern sustainability practices, making them an attractive option for consumers and businesses alike. As technology advances, with new services and web-to-print platforms emerging, DTF Transfers are becoming increasingly accessible for everyone from hobbyists to professional printers. This guide not only introduces the benefits and practical applications of DTF Transfers but also highlights the importance of eco-friendly practices in today’s fashion industry, setting a strong foundation for anyone looking to venture into DTF printing.