DTF Transfers, or Direct to Film transfers, are revolutionizing the custom apparel printing landscape with their innovative approach and remarkable quality. This cutting-edge printing method is rapidly gaining ground against traditional techniques such as screen printing and Direct to Garment (DTG). By understanding how DTF Transfers compare to these well-known alternatives, businesses and designers can make informed decisions that enhance their custom apparel offerings. The versatility, efficiency, and vibrant color capabilities of DTF Transfers make them a favored choice for both small and large production runs. As the demand for high-quality custom apparel increases, exploring DTF Transfers could be your next pivotal step in the world of transfer printing techniques.

When discussing DTF Transfers, it’s also essential to consider the broader context of contemporary printing methods used in the custom apparel industry. Alternative terms you might encounter include film transfer prints and innovative heat transfer options, both of which highlight the adaptability and efficiency of DTF technology. These printing methods stand tall in comparison to established practices like screen printing, providing unique advantages that cater to diverse fabric types and design complexities. As businesses continue to seek cost-effective solutions for personalization, understanding these various printing technologies will enable them to capitalize on the fastest-growing trends in the realm of custom clothing.

Understanding DTF Transfers

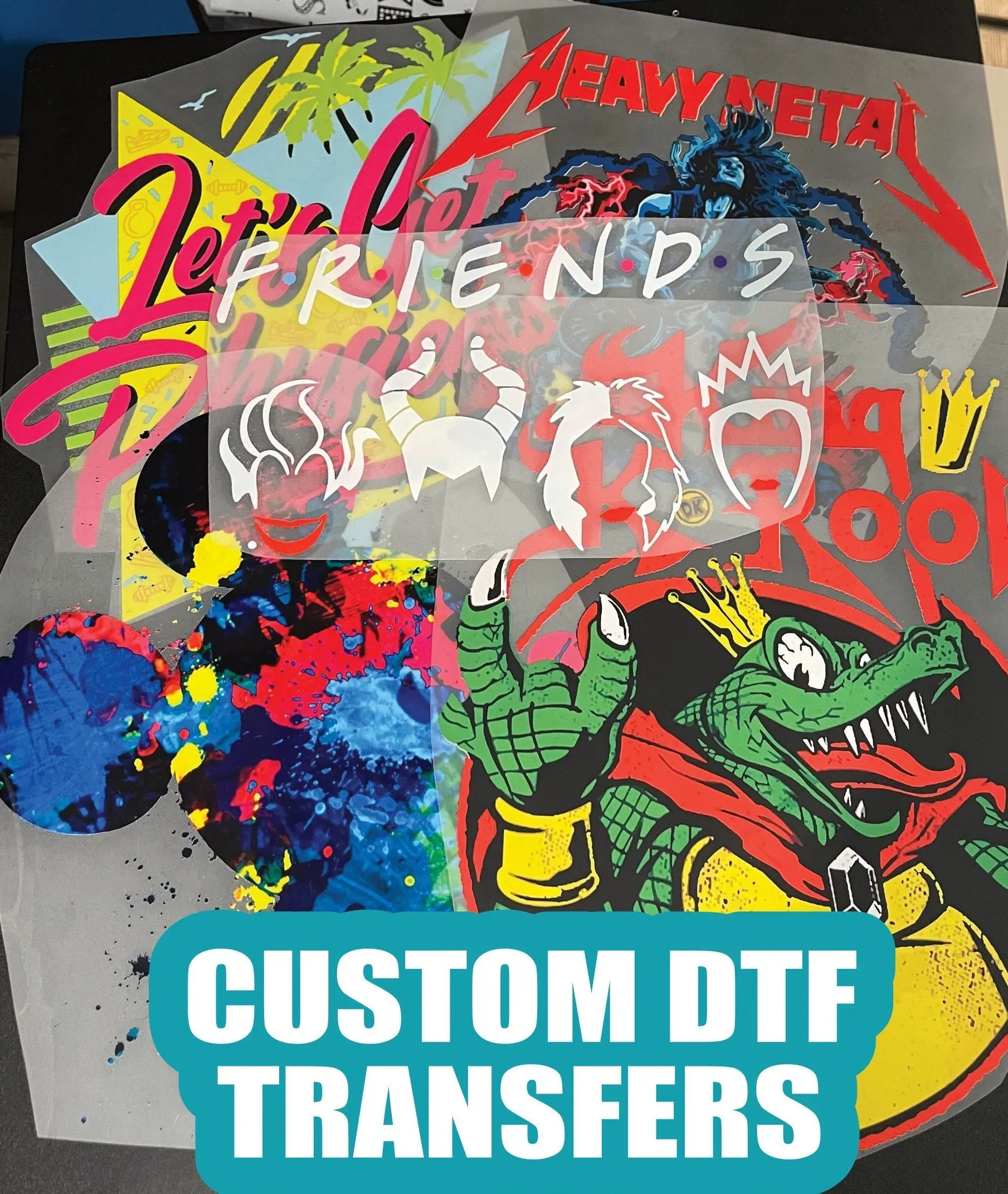

DTF Transfers, or Direct to Film Transfers, represent a cutting-edge solution in the field of custom apparel printing. This innovative technique begins with a specialized film where designs are printed, followed by a powder adhesive application. After printing, the film is heat-pressed onto various fabrics, achieving vibrant results on materials like cotton and polyester. This versatility is crucial for businesses aiming to cater to a wide range of customer preferences, making DTF a standout option compared to older methods such as screen printing.

The technology behind DTF Transfers allows for intricate designs to be transferred with precision, offering a level of color vibrancy that is often unmatched. This process not only facilitates creativity in design but also considerably simplifies the production workflow. Unlike Direct to Garment (DTG), which can be limited by fabric type and often requires longer setup times, DTF provides a more flexible approach suitable for varying production runs.

The Rise of DTF in Custom Apparel Printing

As the demand for personalized clothing continues to rise, DTF Transfers are on the forefront of custom apparel printing innovations. Recent advancements in this technology have significantly improved not just the quality of the prints but also the efficiency of the process. Services like DTFPrinter cater specifically to crafters, emphasizing faster turnarounds and high-quality results, which are essential for small businesses and individual designers.

Market players like Sam’s DTF Transfers have also established themselves in the U.S. by focusing on in-house production techniques. This strategic move allows for greater control over quality and output speed, reinforcing DTF as a reliable printing method. These advancements are transforming the landscape of custom apparel, making DTF a highly sought-after solution that competes well against traditional methods like screen printing and DTG.

Advantages of Choosing DTF Transfers

One of the key advantages of DTF Transfers is their unmatched versatility across different fabric types. This printing method enables businesses to produce designs on a wide range of textiles, including cotton, polyester, and blends, without compromising quality. In contrast, screen printing often requires specific fabrics, restricting the variety of products that can be offered. This adaptability allows businesses to meet diverse customer demands more effectively.

Furthermore, DTF Transfers are renowned for delivering vibrant colors that make designs truly stand out. The finished products are comparable to those produced through digital printing, making DTF a go-to choice for intricate designs that demand color fidelity. This quality factor, combined with the ability to handle small to medium runs without the prohibitive costs associated with screen printing setups, makes DTF Transfers a compelling option for businesses.

Cost Benefits of DTF Printing

Cost efficiency is another significant advantage of DTF Transfers, particularly for shorter production runs. Traditional methods like screen printing entail high setup costs, which can deter businesses from taking on small orders. In contrast, DTF requires a lower initial investment and operates efficiently, resulting in reduced overall printing costs for smaller batches. This aspect proves invaluable for startups and small businesses looking to establish themselves in the custom apparel market.

In addition to lower costs for small runs, DTF technology eliminates the need for multiple screens in multi-color designs. This simplification leads to fewer resources spent on setup and machine time, translating to better profit margins for operations focused on personalized apparel. If budget considerations are a priority, DTF Transfer printing stands out as a budget-friendly solution compared to both screen printing and DTG.

Comparative Analysis: DTF vs. Other Printing Methods

When examining different printing methods, it becomes clear that each has its unique benefits and drawbacks. For instance, while screen printing is highly cost-effective for large batch orders, it falls short in versatility for intricate designs and small runs. On the other hand, Direct to Garment (DTG) excels in detail and intricacy but often struggles with speed and cost-effectiveness for larger orders. This comparison highlights that each printing technique has its strengths and is suited for different applications.

DTF Transfers, however, bridge the gap by combining efficiency with flexibility. This method allows for fast production times without sacrificing the detail needed for high-quality designs. Businesses that choose DTF can cater to diverse orders, from one-offs to larger batches, positioning themselves advantageously in the competitive custom apparel landscape.

Future Trends in DTF Transfers and Custom Apparel

As the custom apparel printing industry evolves, DTF Transfers are anticipated to become an increasingly dominant choice due to ongoing advancements in technology. The rapid growth of this printing method is being fueled by innovations that enhance both production speed and quality. Additionally, as more services specialize in DTF printing, the accessibility of this technology is likely to broaden, empowering more creators to utilize this method in their designs.

Moreover, as sustainable practices gain importance in manufacturing, DTF technology’s ability to produce less waste compared to traditional methods may position it as a more eco-friendly option for businesses. As awareness grows, companies that adopt DTF Transfers could find themselves ahead of the curve in catering to a more environmentally conscious consumer base.

Frequently Asked Questions

What are DTF Transfers and how do they work?

DTF Transfers, or Direct to Film Transfers, involve printing designs onto a special film which is then coated with a powder adhesive. This film is heat-pressed onto various fabric types, allowing for vibrant and intricate designs to transfer onto cotton, polyester, and blends.

How do DTF Transfers compare to screen printing?

DTF Transfers offer greater flexibility with fabric types and faster production turnaround times than screen printing. While screen printing is cost-effective for mass production, it requires specific setups for different colors, making it less versatile for intricate designs.

Are DTF Transfers a better choice than Direct to Garment (DTG) printing?

DTF Transfers generally provide quicker turnaround and lower costs for small production runs compared to DTG printing. While DTG excels in detail for complex designs, DTF is more efficient for varied fabric types and simpler setups.

What are the advantages of using DTF Transfers for custom apparel printing?

DTF Transfers offer several advantages including versatility across different fabric types, vibrant color output, quick turnaround times, and cost-effectiveness for smaller print runs, making them an appealing option for custom apparel printing.

What are the potential drawbacks of DTF Transfers?

While DTF Transfers provide good quality prints, there are concerns regarding long-term durability and initial setup costs for equipment, which may be higher compared to simpler printing methods like screen printing.

Can DTF Transfers be used for large printing orders?

Yes, DTF Transfers can be used for larger orders, although for mass production, screen printing may remain more cost-efficient. However, DTF’s quick setup and ability to handle diverse designs make it a competitive choice even for larger prints.

| Feature | DTF Transfers | Screen Printing | Direct to Garment (DTG) |

|---|---|---|---|

| Versatility | Can be used on various fabric types including cotton and polyester. | Best for specific materials with higher setup costs. | Great for many fabrics but typically limited to cotton and blends. |

| Vibrant Colors | Produces vibrant, intricate designs with color accuracy. | Good for solid colors but less effective for complex designs. | Ideal for detailed and complex designs but pricey for larger orders. |

| Efficiency | Quick turnaround times with no need for multiple setups. | Time-consuming due to setup for different colors. | Slower than DTF, especially for larger runs. |

| Cost-Effectiveness | More economical for small runs without high initial costs. | Better for large runs due to reduced per-unit costs but high setup costs. | Can be costly for smaller runs or multiple colors. |

| Durability | Concerns about long-term durability with heavy washing. | Offers superior durability for high-use garments. | Generally durable but may not withstand a lot of washes as well as screen printing. |

| Initial Setup Costs | Can be higher due to equipment requirements. | Higher due to screen setup costs, especially for color variations. | May have lower entry costs depending on DTG printer access. |

Summary

DTF Transfers are revolutionizing the custom apparel printing industry by offering a unique combination of versatility, vibrancy, and efficiency that appeals to businesses of all sizes. As a flexible printing method, DTF Transfers allow for the production of intricate designs on a wide array of fabrics, helping designers bring their visions to life while catering to diverse customer needs. While traditional methods like screen printing and DTG remain popular, the advantages of DTF Transfers—including quicker turnaround times and cost-effective solutions for small runs—make them an increasingly attractive option in the competitive landscape of custom printing. Therefore, as you explore your custom apparel printing options, DTF Transfers stand out as a compelling choice for balancing quality and efficiency.