DTF printing techniques, or Direct-to-Film printing, represent a groundbreaking approach in the realm of graphic transfer technology. This innovative method enables creators to achieve high-quality transfers that seamlessly adhere to various materials, making it a preferred choice for custom apparel and promotional items. As these printing techniques evolve, the focus on eco-friendly DTF printing practices also rises, appealing to a market that values sustainability. Furthermore, optimized printing processes enhance efficiency and output, while versatile DTF applications expand the possibilities for imaginative designs across diverse media. Whether you are a business or a creative individual, understanding the nuances of DTF printing techniques can elevate your project outcomes to stunning new heights.

The realm of Direct-to-Film printing encompasses a variety of advanced graphic transfer methodologies that are reshaping how designs are applied across materials. Often referred to as DTF techniques, these practices utilize state-of-the-art systems for producing vibrant and durable graphics. This process has gained popularity due to its potential to deliver exceptional transfer quality, while also being an environmentally responsible choice with eco-friendly materials. As the industry shifts towards more optimized workflows, designers are finding new avenues for creativity, including versatile applications that extend beyond traditional textiles. Learning about these innovative printing techniques is essential for anyone looking to stay ahead in the competitive world of custom printing.

Understanding Direct-to-Film (DTF) Printing Techniques

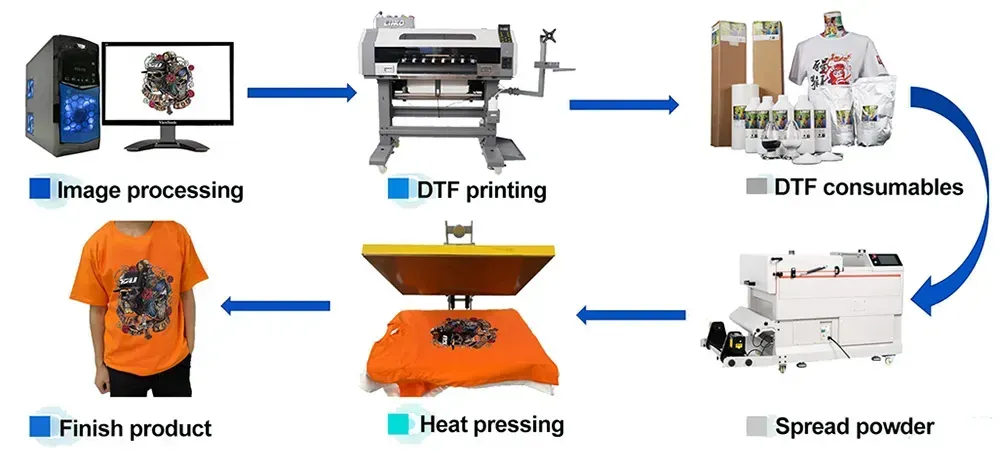

Direct-to-Film (DTF) printing has rapidly gained traction in the printing industry due to its innovative approach to producing high-quality transfers. Unlike traditional screen printing methods, DTF printing involves printing graphics onto a special film, which is then transferred onto the desired substrate. This technique not only allows for vibrant color reproduction and intricate designs but also ensures that the finished products maintain their aesthetic appeal even after multiple washes. By employing specialized inks that adhere well to the transfer films, DTF printing offers an exciting alternative for those aiming to make a bold statement with their apparel and promotional items.

What sets DTF printing apart is its ability to accommodate a diverse range of materials. Whether it’s cotton, polyester, or blended fabrics, DTF techniques can easily adapt to various surfaces, making it a go-to choice for custom apparel businesses. Furthermore, the simplified production process can help businesses cater to smaller orders while maintaining quality, allowing for greater flexibility in meeting clients’ needs. This adaptability not only enhances the design possibilities but also positions DTF printing as a valuable tool for entrepreneurs and creative professionals.

The Importance of High-Quality Transfers in DTF Printing

High-quality transfers play a crucial role in the success of DTF printing techniques. By utilizing fully optimized transfer films and advanced ink formulations, printers can achieve remarkable results that stand the test of time. The quality of the transfer directly affects the visual impact of the printed material, making it essential to choose high-resolution films that enhance color saturation and detail. This emphasis on quality mitigates the risk of prints fading or cracking over time, which can occur with inferior materials.

Investing in top-tier transfer films can transform a simple design into a captivating visual masterpiece. Moreover, optimal curing methods during the transfer process enable the ink and film to bond well, ensuring durability and longevity. This dual focus on transfer quality and printing techniques solidifies DTF printing as a premier choice for businesses looking to deliver exceptional custom apparel and promotional items that leave a lasting impression.

Optimized Printing Processes for Efficiency and Quality

Optimized printing processes are pivotal for achieving both efficiency and quality in DTF printing. By incorporating smart automation in pre-treatment and post-curing stages, printing businesses can significantly enhance their workflow, allowing for quicker turnaround times without sacrificing print quality. For instance, modern DTF printers equipped with dual print head technology can execute high-speed prints while maintaining clarity, making it easier to handle larger client orders.

Moreover, advancements in workflow management software allow businesses to streamline operations further by keeping track of design files and print jobs. This organizational capability leads to better resource management, assisting companies in efficiently scaling their DTF printing operations. The combination of these optimized processes ensures that businesses can meet customer demands promptly while always delivering stunning and reliable prints.

Eco-Friendly Innovations in DTF Printing Materials

As sustainability becomes a focal point for various industries, DTF printing is not left behind. The introduction of eco-friendly inks and biodegradable transfer films represents a significant advancement in reducing the environmental impact of printing operations. These innovations ensure that high-quality prints can be produced without compromising the planet’s health, making them attractive for environmentally-conscious consumers.

Furthermore, the shift towards using recyclable materials in DTF printing aligns with growing consumer demand for sustainable practices. By adopting eco-friendly materials, businesses not only contribute positively to environmental preservation but also position themselves as responsible brands that resonate with their target audience. This commitment to sustainability can create a competitive edge and foster long-term loyalty among a customer base that values ethical consumption.

Leveraging Custom Software Solutions for DTF Success

The integration of custom software solutions within DTF printing operations has revolutionized the approach to design management and output quality. With sophisticated color management tools and layout configuration options, designers can seamlessly transfer their digital creations into high-quality physical prints. This advancement minimizes discrepancies between digital designs and final products, enhancing the overall user experience.

Moreover, these software systems often include features that allow for real-time adjustments to color profiles and print settings, which can lead to significant time savings during the production process. By reducing the amount of test printing needed, businesses can optimize their materials and resources effectively. The result is a more efficient workflow that yields stunning prints, solidifying DTF printing’s position at the forefront of modern printing techniques.

Exploring Versatile Applications of DTF Printing

One of the most appealing aspects of DTF printing is its incredible versatility. While originally designed for textiles, this technique has expanded its boundaries to include a wide variety of surfaces, such as wood, glass, and metal. This adaptability enables businesses to create unique and personalized items that capture customers’ attention, broadening their potential markets and opportunities.

The capability of DTF printing to work on both light and dark substrates enhances its versatility further. Custom apparel businesses can utilize DTF technology to produce everything from t-shirts and bags to intricate signage and promotional products. By embracing these varied applications, companies can diversify their offerings, picking up new customer segments and driving growth within their industries.

Frequently Asked Questions

What are the benefits of high-quality transfers in DTF printing techniques?

High-quality transfers in DTF printing techniques ensure vibrant colors and intricate designs that enhance the overall appeal of printed items. These transfers, created using specialized inks and advanced films, offer durability and resistance to wear, making them ideal for custom apparel and promotional products.

How can optimized printing processes improve my DTF printing experience?

Optimized printing processes in DTF printing enhance workflow efficiency and significantly reduce production time. By implementing automated systems and advanced print technology, businesses can quickly fulfill large orders while maintaining high quality, ensuring that every print meets the precise expectations of customers.

What eco-friendly materials are used in modern DTF printing?

Modern DTF printing techniques utilize eco-friendly materials such as water-based inks and biodegradable transfer films. These sustainable options not only produce high-quality prints but also resonate with environmentally conscious consumers, helping businesses align with current green practices.

How do custom software solutions enhance DTF printing quality?

Custom software solutions tailored for DTF printing allow for better control over color management and layout configurations. This advancements help ensure that digital designs translate accurately to physical prints, reducing the need for test prints and thereby optimizing material usage.

What types of substrates can be used in versatile DTF printing applications?

Versatile DTF printing techniques are not limited to textiles; they can print on an array of substrates, including wood, glass, and metal. This adaptability allows businesses to explore a wide range of branding opportunities, creating custom products that cater to various industries and markets.

How does DTF printing compare to traditional printing methods?

DTF printing techniques offer several advantages over traditional methods, including the ability to produce high-quality transfers, faster production times, and the capacity to print on a broader range of materials. These advancements position DTF printing as a flexible and efficient choice for modern printing needs.

| Technique | Description | Benefits |

|---|---|---|

| High-Quality Transfers | Utilizes advanced inks and transfer films for high-resolution outputs. | Delivers vibrant colors and durability for everyday wear. |

| Optimized Printing Processes | Streamlines workflow with automated pre-treatment and dual print head technology. | Reduces production time while improving quality and efficiency. |

| Eco-Friendly Materials | Uses water-based inks and biodegradable films to minimize environmental impact. | Attracts customers interested in sustainable practices. |

| Custom Software Solutions | Integrates software for better design control and color accuracy. | Increases efficiency and decreases material waste. |

| Versatile Applications | Allows printing on various substrates beyond textiles. | Expands market opportunities for branding and promotional items. |

Summary

DTF printing techniques are at the forefront of the printing industry, providing remarkable advancements that cater to both creatives and businesses. Emphasizing high-quality transfers and optimized processes ensures that the results are not only vibrant but also efficient. The adoption of eco-friendly materials showcases a commitment to sustainable practices, appealing to today’s environmentally conscious consumers. Furthermore, the integration of custom software solutions and the capability to print on a diverse range of materials highlight the versatility that DTF printing offers. By leveraging these techniques, businesses can significantly enhance their offerings and remain competitive in an ever-evolving marketplace.