DTF vs DTG are two popular direct-to-garment methods shaping how apparel brands approach printing, from small-batch drops to fast on-demand campaigns, and each option carries a distinct set of trade-offs, highlighting how this choice influences product storytelling, supplier relationships, and the speed of market introduction. Choosing between them involves weighing color depth, fabric compatibility, speed, durability, and total cost of ownership across a varied product mix and evolving consumer expectations; this framework also helps stakeholders compare risk, branding alignment, and the potential to offer customization at scale. DTF printing advantages are often cited for bold color transfer on a wide range of fabrics and for flexible on-demand workflows that fit scattered inventory and global fulfillment; that said, the choice should reflect your price targets, expected margins, and the ability to maintain color integrity over many washes in real-world conditions and across a spectrum of garment types. DTF facilitates quick setup and simple inventory planning, with reliable performance on dark and light substrates, which can help you scale product lines while maintaining margins; it also influences maintenance cycles, energy usage, and the training required for staff to execute consistent results. Understanding these dynamics in the context of your brand roadmap can guide smarter choices about production speed, quality, customer satisfaction, and long-term growth, while factoring in supplier relationships and market timing.

Beyond the technical labels, brands often describe this decision in terms of film transfers versus direct-to-fabric printing to capture the practical realities of production. A web of related considerations includes color fidelity on diverse substrates, tactile hand feel, downtime for maintenance, and the ability to fulfill on demand with consistent results. When brands map the journey from design to delivery, they rely on terms like transfer-based execution and fabric-safe inks, rather than only the shorthand DTG or DTF. The clear takeaway is that each approach interacts with fabric type, end-use, and sustainability goals, so testing across key products yields more actionable insights than labels alone. In practice, many brands adopt a hybrid strategy: leveraging film-based transfers for versatility and on-demand variety, while reserving direct-to-garment printing for premium, cotton-forward lines.

DTF vs DTG: Which Path Is Best for Your Apparel Brand?

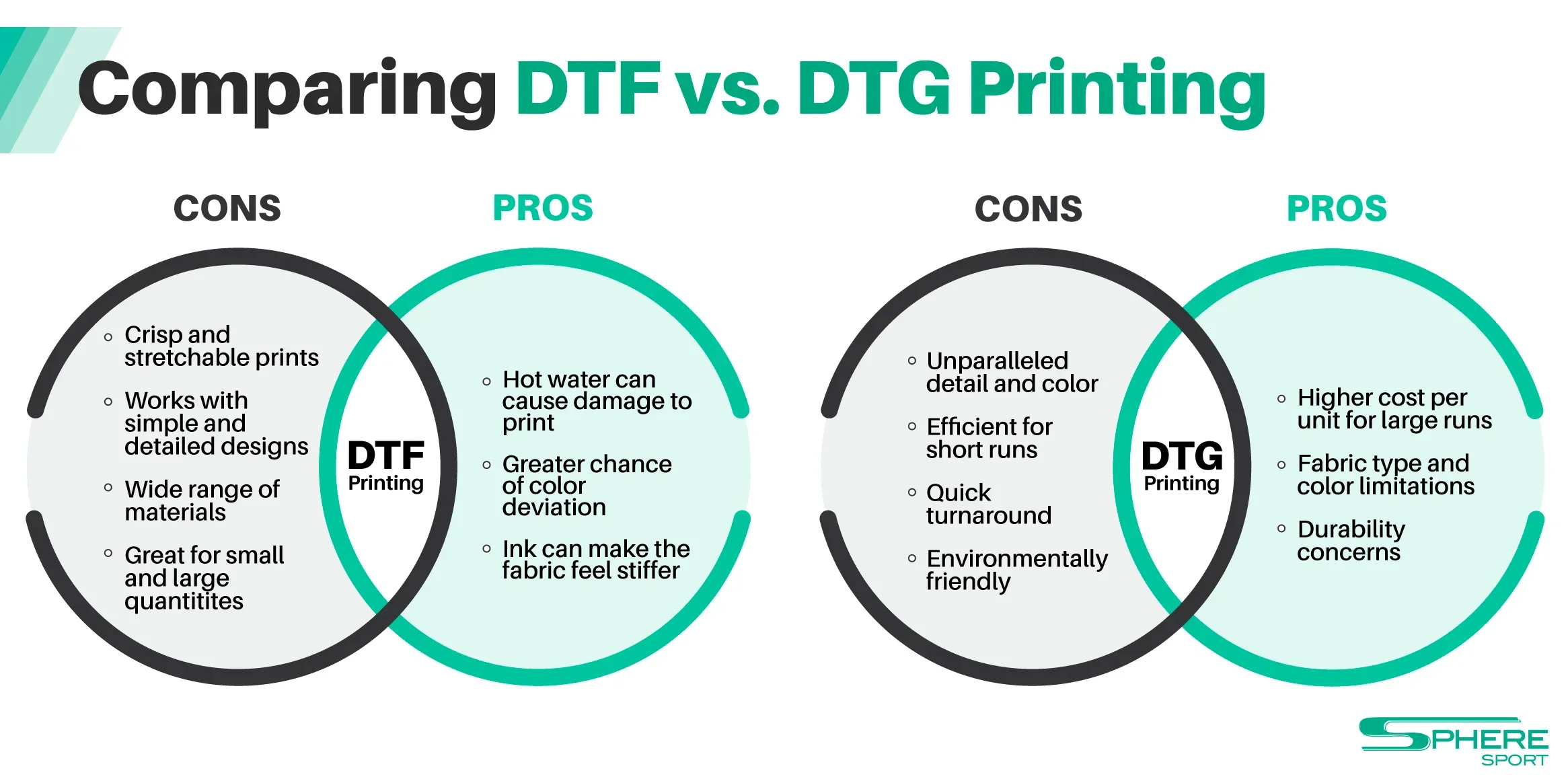

Choosing between direct-to-film (DTF) and direct-to-garment (DTG) is a foundational decision for an apparel brand. Both methods offer distinct strengths, trade-offs, and ideal use cases, and the right choice depends on your product mix, production workflow, and customer expectations for hand feel and durability. By understanding how each process integrates with your brand roadmap, you can align your printing strategy with your long-term growth plans and inventory philosophy.

In practice, the decision hinges on fabric variety, color fidelity, and operational needs. DTF excels when you need versatility across fabrics, bold colors on dark backgrounds, and on-demand, scalable transfers. DTG shines on premium cotton garments with soft hand feel and intricate gradients on light backgrounds. A clear framework that weighs fabric mix, desired hand feel, turnaround times, and cost of ownership helps brands avoid a one-size-fits-all approach and instead adopt a strategy that suits their catalog.

DTF printing advantages for a versatile apparel line

DTF printing advantages begin with material flexibility. Transfers can be applied to cotton, polyester blends, and dark fabrics with strong color saturation, enabling a wider fabric palette without retooling the fabric base. This versatility is especially valuable for brands that offer a mixed material lineup or seasonal fabrics, as it reduces the risk of stranded inventory and expands design possibilities.

Beyond fabric compatibility, DTF delivers compelling color vibrancy and sharp detail that translates well to bold graphics, logos, and typography. The transfer-based approach also supports on-demand workflows, allowing designs to be stored, queued, or shipped as needed, which aligns well with print-on-demand models and minimizes stock-keeping requirements while maintaining fast fulfillments.

DTG cost and performance: DTG vs DTF cost comparison for scaling

Cost considerations go beyond the per-unit price and should include equipment, consumables, maintenance, and labor. A DTG system often carries a higher upfront investment, especially multi-head models designed for high-detail output on light fabrics. In contrast, DTF machinery and consumables—film, adhesive powders, and transfer sheets—can offer a lower barrier to entry and more scalable expansion as you diversify fabric types.

When evaluating long-term value, consider the cost of ownership and throughput. DTG may deliver fast single-garment production for high-detail images on cotton but can incur pretreatment and white-ink costs on dark backgrounds that impact unit economics. DTF, meanwhile, can optimize batch production, reduce setup complexity, and achieve efficient turnaround across a broader fabric mix, contributing to a favorable cost comparison in many scaling scenarios.

Direct-to-film vs direct-to-garment durability: A practical comparison

Durability is a key consideration for brands aiming for lasting wash performance and customer satisfaction. Direct-to-film durability depends on well-calibrated adhesion and curing, as well as the strength of the film transfer on different fabrics. When properly cured, DTF can offer excellent durability and color fastness across a variety of substrates, though hand feel and edge finishing should be monitored during long-term wear tests.

Direct-to-garment durability centers on ink chemistry, fabric interaction, and post-press curing. DTG prints on cotton often exhibit outstanding wash durability and brightness, with a softer hand feel when properly cured. However, performance can vary on blends and dark fabrics unless pretreatment and white ink opacity strategies are optimized. Brands should run standardized wash tests to compare long-term results under their typical usage patterns.

DTF workflow and setup: From design to transfer

DTF workflow and setup cover the end-to-end process from artwork to finished transfer. Start with digital artwork prepared for film output, then print onto a transfer film using suitable inks. After printing, apply a protective powder, cure the powder to activate adhesion, and prepare the sheet for transfer with precise cutting and heat pressing.

A well-managed DTF setup emphasizes consistency across batches: calibrated heat presses, controlled timing, and proper ventilation for powders and inks. The modular nature of DTF lines supports scalable production, with the ability to pre-prepare transfers and batch process them to meet demand without tying up individual garments. Training and standard operating procedures help ensure repeatable results and reduce waste.

Apparel brand printing methods: Crafting a hybrid approach that fits

Apparel brand printing methods increasingly embrace hybrid strategies that combine the strengths of DTF and DTG. By leveraging DTF for fabric versatility and fast turnarounds and DTG for premium cotton items with soft hand and photorealistic detail, brands can optimize quality, inventory, and customer experience. This approach aligns with diverse product lines and variable demand while maintaining brand consistency.

A hybrid model also supports smarter inventory management and scalable growth. Using DTF for on-demand transfers across dark or mixed fabrics reduces the need for stock-keeping of every color and material, while DTG can drive premium campaigns on white or light backgrounds. This integrated approach reflects contemporary apparel brand printing methods, where the goal is to maximize impact, minimize risk, and deliver reliable performance across a dynamic product catalog.

Frequently Asked Questions

DTF printing advantages: What makes DTF vs DTG more versatile for fabric variety and on-demand production?

DTF offers broad fabric compatibility (cotton, blends, polyester; dark fabrics work well) and high color vibrancy. It enables on-demand or print-on-demand workflows without stocking many garment variants, and transfers can be stored and applied later. Caveats include a potentially firmer hand feel on some fabrics and extra steps (powder coating, curing) that require precise timing and pressure.

DTG vs DTF cost comparison: How do upfront and ongoing costs compare for an apparel brand?

DTG printers typically require higher upfront investment, especially multi-head systems, while DTF lines can be more affordable to scale. Ongoing consumables differ: DTG needs pretreatment and white ink for opacity on dark fabrics; DTF uses film with adhesive powders. Throughput and labor affect total cost—DTG may be faster for single, high-detail items; DTF can be more economical for mixed fabrics and batch transfers.

Direct-to-film vs direct-to-garment durability: Which method holds up better in wash tests across fabrics?

Both methods can be durable with proper curing and protective coatings. DTG often delivers a soft hand and bright results on cotton but requires correct pretreatment and curing, especially on dark fabrics. DTF can show excellent wash resistance across a wider range of fabrics when the transfer, adhesive, and powder are properly applied. Durability ultimately depends on ink chemistry, substrate, and pressing quality.

DTF workflow and setup: What does the typical DTF workflow look like, and how does it affect production speed?

A typical DTF workflow includes artwork preparation, film printing, adhesive powder application, curing, transferring with heat, and finishing. This modular process supports batch and on-demand production, enabling flexible line setups for mixed fabrics. Key efficiency factors are precise powder adhesion, correct heat press temperature and dwell time, and organized workflows to minimize handling and rework.

Apparel brand printing methods: How do DTF and DTG fit into an apparel brand’s printing strategy for catalog variety and inventory?

DTF provides versatility across fabrics and colors, making it strong for on-demand production and diverse catalog items. DTG shines on premium cotton with high-detail imagery and a soft hand feel. Brands often use a hybrid approach: DTG for cotton-heavy items and high-detail prints, DTF for dark fabrics, performance fabrics, and wider material ranges to reduce stocking complexity.

DTF vs DTG: Which method is better for high-detail photography on light fabrics vs bold color on dark fabrics?

DTG is excellent for high-detail photography and subtle gradients on light fabrics, offering a soft hand. DTF is typically favored for bold, color-dense graphics on dark or varied fabrics and for broader material compatibility. Your choice depends on product mix, desired hand feel, and production efficiency; many brands adopt a hybrid strategy to balance quality and versatility.

| Aspect | DTF | DTG |

|---|---|---|

| What it is and how it works | DTF prints design on transfer film; coat with adhesive powder; heat-press the transfer onto fabric; versatile across fabrics (including dark) | DTG prints directly on fabric with water-based inks; cured; best on 100% cotton or light fabrics; offers a soft hand |

| Strengths | DTF: versatile across fabrics, bold color and sharp detail, good for batch/on-demand; supports mixed fabrics without reprinting on every garment | DTG: soft hand on cotton, high-detail gradients, minimal post-processing |

| Limitations | DTF: hand feel can be slightly stiffer; potential transfer edge residues if not applied precisely; extra powder curing steps | DTG: best on light fabrics; pretreatment and opacity challenges on dark fabrics; slower for high-volume production |

| Fabric compatibility | Broad fabric compatibility including cotton, blends, polyester, and dark fabrics | Best on 100% cotton or high cotton content blends; white base on dark fabrics |

| Costs & scalability | Lower upfront investment in many cases; scalable for batches; film and adhesive powder systems vary by volume | Higher upfront cost for printers and maintenance; pretreatment, white ink, and ongoing upkeep |

| Throughput & speed | Efficient batch prep; quick transfer steps; well-suited for on-demand and mixed fabrics | Slower per unit at high volumes; fast for single designs or small batches on cotton |

| Hand feel & durability | Slightly stiffer hand; durability with proper curing | Soft hand; durable on cotton when cured well |

| Use cases / Brand fit | Wide fabric variety, fast turnaround, complex graphics on dark fabrics | Premium cotton items with photo-like imagery on light fabrics; small runs |

| Sustainability considerations | On-demand capability can reduce overproduction; manage waste (film, powder) | Eco-friendly potential with water-based inks; pretreatment impact on water use; optimize waste |

Summary

DTF vs DTG presents a strategic decision for apparel brands seeking the right balance of fabric versatility, hand feel, and production efficiency. A hybrid approach—leveraging DTG for premium cotton items and high-detail imagery, and DTF for broad fabric compatibility and scalable on-demand production—often delivers the best overall outcomes. By aligning product mix, cost of ownership, and customer expectations for durability and wash performance, you can design a printing strategy that supports growth while maintaining brand consistency and profitability.