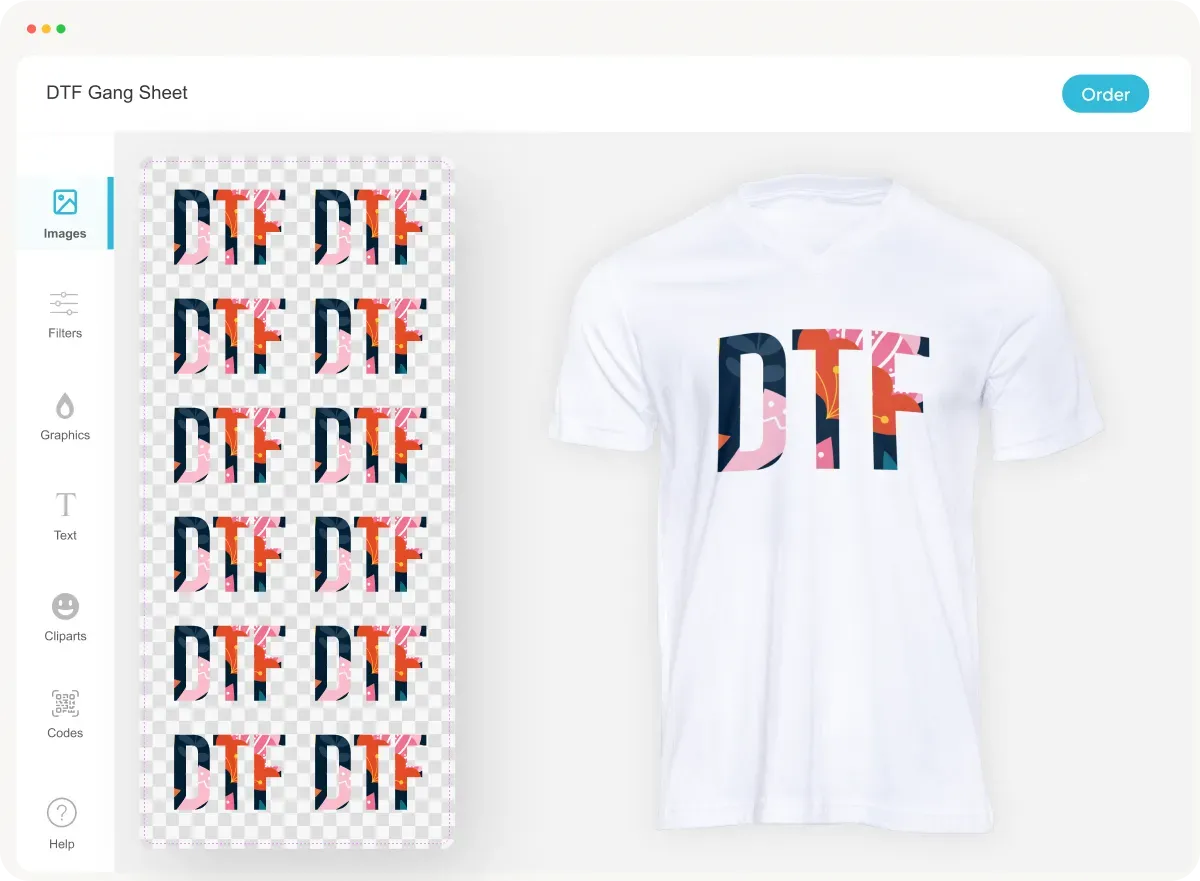

In the modern era of apparel decoration, mastering techniques such as the DTF Gangsheet Builder has become essential for businesses aiming to maximize profits. This innovative method transforms the way designs are produced, allowing for efficient use of materials while ensuring high-quality prints. With direct-to-film printing, companies can create custom gang sheets that cater to diverse customer demands, making their products stand out in a competitive market. By embracing cost-efficient DTF strategies, businesses not only reduce waste but also enhance their profit margins. Dive into the world of DTF gangsheet building to discover how you can elevate your production capabilities and meet consumer expectations.

Exploring Direct-to-Film (DTF) gang sheet techniques opens up a realm of possibilities for efficient textile printing solutions. This approach allows businesses to streamline their production processes by grouping multiple designs or images onto a single print sheet, thereby optimizing costs and resources. Known for its flexibility, DTF printing allows for high-resolution outputs on various fabrics while meeting the rising demand for customized products. By leveraging the advantages of gang sheet printing, companies tap into market trends that enhance customer satisfaction and ensure repeat business. Adopting these innovative printing methods can lead to substantial improvements in both operational efficiency and profitability.

Understanding Direct-to-Film Printing

Direct-to-Film (DTF) printing is a revolutionary process that has changed the landscape of textile printing. It allows businesses to print intricate designs onto a special film which is then transferred onto fabrics. This innovative technique offers several advantages, including higher versatility with fabric types, which means businesses can cater to a wider market segment. Furthermore, DTF printing boasts superior print quality compared to traditional methods, as it preserves vibrant colors and intricate details, ensuring that every design pops on product surfaces.

The appeal of DTF printing lies in its efficiency and cost-effectiveness. Businesses can easily print designs in bulk, reducing costs per unit significantly. With the ability to work with various substrates, it meets customer demands across different markets, from fashion apparel to promotional products. Overall, understanding DTF printing is crucial for businesses looking to optimize their operations and stay competitive in an evolving industry.

The Benefits of DTF Gangsheet Builder Techniques

Implementing DTF gangsheet builder techniques allows businesses to enhance their workflow efficiency profoundly. By combining multiple designs on a single sheet, production costs are reduced significantly due to minimized material waste. This technique ensures that fabric and ink resources are utilized optimally, leading to substantial savings. Additionally, the gangsheet approach streamlines the printing process, enabling faster turnaround times, which is essential in meeting customer demands swiftly.

Moreover, custom gang sheets can be tailored to specific customer needs, improving customer satisfaction and loyalty. Businesses can cater to a range of preferences, whether it be eclectic designs for younger audiences or professional looks for corporate clients. This customization not only boosts sales potential but also allows businesses to introduce limited editions, driving up their value and appeal in a crowded marketplace.

Maximizing Profits with Cost Efficiency in DTF

Cost efficiency is a key pillar in maximizing profits with DTF printing. By employing DTF gangsheet techniques, businesses can significantly reduce their production costs. When multiple designs are printed together, the costs associated with setup time and materials decrease, creating a more streamlined production process. This efficiency not only optimizes the use of resources but also enables businesses to offer more competitive pricing to customers without sacrificing their profit margins.

Moreover, due to the enhanced efficiency of DTF printing combined with gangsheet techniques, businesses can increase their output without the necessity for substantial investments in new machinery. This scalability means that whether a business is large or just starting out, they can adjust rapidly with customer demand while keeping costs in check. As a result, they can maintain a healthy profit margin even in a competitive market.

Quality Control Techniques in DTF Printing

Ensuring a high level of quality in DTF printing is essential for sustaining business growth. Employing advanced quality control techniques throughout the printing process can significantly enhance the final product’s appeal. Businesses should invest in high-quality DTF printers equipped with precise ink application and color management systems. This investment not only raises the standard of the output but can also lead to fewer errors and reprints, ultimately saving resources.

Conducting test prints and refining gangsheet designs is another crucial aspect of maintaining quality. Regularly assessing output allows businesses to ensure that customer expectations are met consistently. High-quality prints will not only attract new customers but will also lead to repeat business, fostering long-term relationships and enhancing profitability in the long run.

Adapting DTF Practices to Market Trends

The textile industry is rapidly evolving, with consumers increasingly demanding eco-friendly practices. By adapting DTF practices to embrace sustainable materials and techniques, such as using water-based inks and biodegradable films, businesses can align themselves with market trends. This proactive approach to sustainability not only improves the brand’s image but can also appeal to a broader audience that values eco-conscious choices.

Incorporating sustainable practices into DTF printing also presents an opportunity for cost savings. By using materials that generate less waste, companies can reduce disposal costs and material expenses. Staying ahead of market trends not only increases competitiveness but fosters innovation within the business, positioning them as leaders in the industry.

Training and Workshops for DTF Gangsheet Techniques

Investing in employee training and workshops is vital for mastering DTF gangsheet building techniques. Various manufacturers and experts in the field offer comprehensive training sessions that cover everything from design software to printing practices. By equipping employees with advanced skills and knowledge, businesses can ensure high-quality outputs while maintaining efficiency.

Moreover, continuous education in DTF printing allows businesses to keep pace with technological advancements and changing consumer preferences. A well-trained workforce is not only more productive but also more adaptable, which is crucial for responding to market demands quickly. Ultimately, investing in training translates directly into increased profitability and a stronger competitive edge.

Frequently Asked Questions

What are DTF Gangsheet Builder Techniques and how do they work?

DTF Gangsheet Builder Techniques involve printing multiple designs onto a single Direct-to-Film sheet, enabling efficient production and customization. This method optimizes material use, reduces costs, and increases productivity, ultimately helping businesses maximize profits.

How does DTF printing enhance cost efficiency for gang sheets?

DTF printing enhances cost efficiency by allowing multiple designs to be printed simultaneously on one film. This minimizes waste and lowers production costs per unit, leading to a significant increase in profit margins for businesses.

Can I customize products using DTF Gangsheet Builder Techniques?

Yes! DTF Gangsheet Builder Techniques allow for exceptional customization of products. Businesses can cater to diverse customer preferences by creating personalized gang sheets with various designs, which can drive higher sales and improve profit margins.

What role does print quality play in DTF Gangsheet Techniques?

Print quality is crucial in DTF Gangsheet Techniques. High-quality DTF printing ensures that designs are vibrant and durable, which attracts customers and enhances brand reputation. Businesses focused on quality control see higher customer satisfaction and repeat purchases.

Why is training important for effectively using DTF Gangsheet Builder Techniques?

Training is vital for mastering DTF Gangsheet Builder Techniques as it enhances operators’ skills and knowledge in DTF printing. Well-trained employees can optimize production efficiency and quality, directly influencing profit maximization.

How can I stay updated on trends in DTF printing and gang sheet techniques?

To stay updated on DTF printing trends and gang sheet techniques, regularly attend workshops, subscribe to industry newsletters, and follow expert blogs. Keeping informed about new materials and consumer preferences helps businesses adapt and remain competitive.

| Aspect | Details |

|---|---|

| What is DTF Printing? | Printing designs onto plastic film, then transferring to fabrics using heat and pressure. Offers fabric compatibility and design resolution improvements. |

| Cost Efficiency and Scaling Production | Utilizes gang sheets to reduce costs per unit, minimize waste, and increase production efficiency. |

| Customizing Products for Higher Profit Margins | Allows for personalization of products to attract diverse customer bases and increase sales prices. |

| Quality Control and Printing Techniques | High-quality DTF printers improve print resolution, leading to repeat customers and enhanced output quality. |

| Adapting to Market Trends | Integration of eco-friendly practices, such as water-based inks, to align with consumer preferences and improve brand image. |

| Training and Workshops | Investing in skill development through training sessions to enhance proficiency in DTF printing techniques. |

Summary

DTF Gangsheet Builder Techniques are essential for businesses aiming to maximize profits within the apparel decoration industry. By leveraging cost-efficient production strategies, focusing on quality control, and aligning with market trends, companies can not only enhance their operational efficiencies but also ensure higher profitability. The integration of these advanced techniques, coupled with ongoing training and investment in quality equipment, represents a transformative approach in the competitive landscape of DTF printing. As such, adopting DTF Gangsheet Builder Techniques not only positions a business to thrive but also allows for innovative customization that resonates with evolving consumer demands.