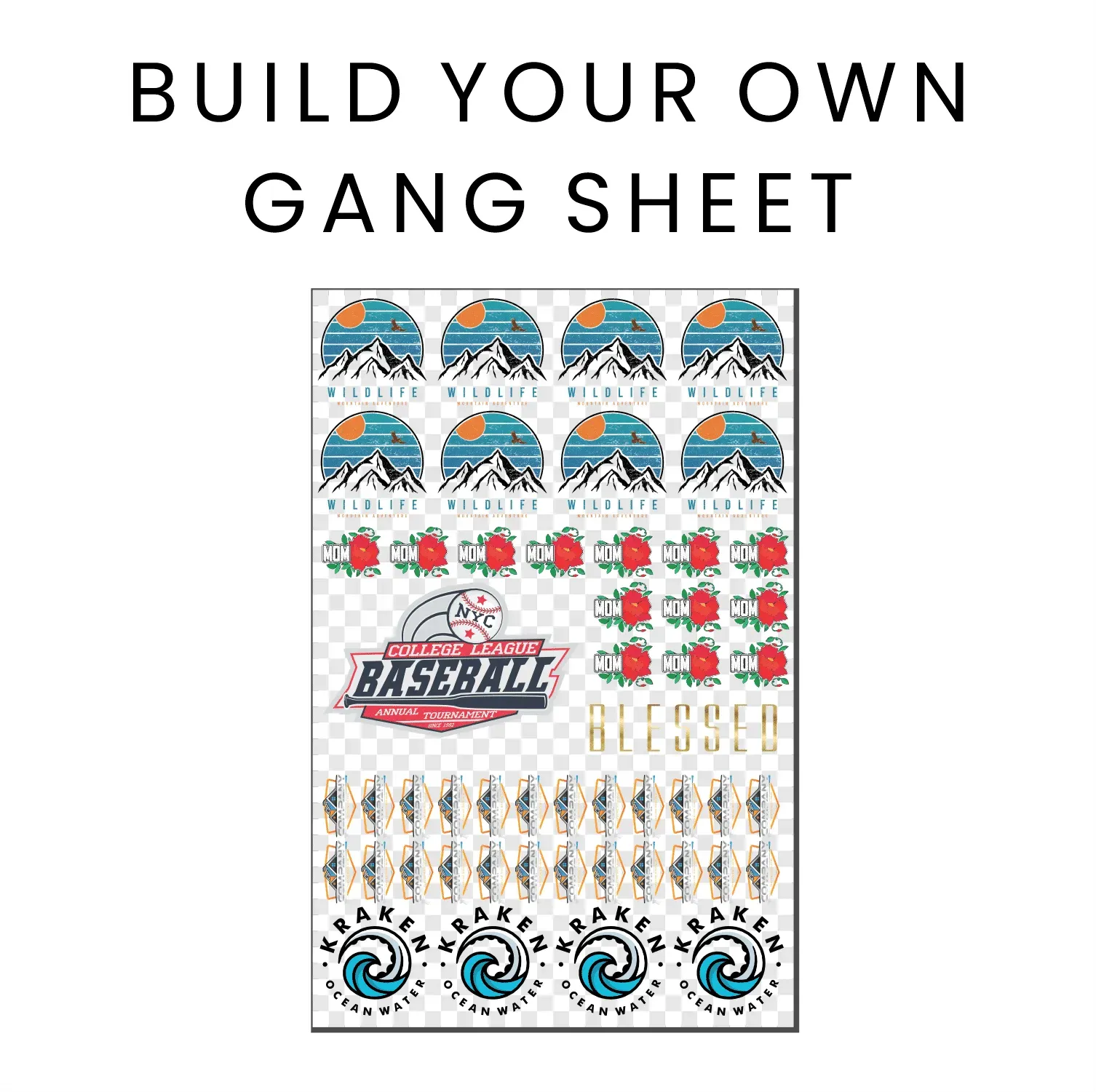

In the textile printing industry, the DTF Gangsheet Builder has emerged as a revolutionary tool that allows print companies to enhance their output and streamline operations like never before. This advanced Direct-To-Film (DTF) printing technology optimally facilitates the creation of multiple designs on a single sheet, significantly improving print production efficiency. Unlike traditional screen printing, which often involves tedious setup processes, the DTF Gangsheet Builder connects speed and quality, catering to the growing demand for customization in fabric prints. As businesses increasingly seek cost-effective printing solutions that guarantee vibrant and durable results, DTF printing stands at the forefront of industry advancements. Explore how the DTF Gangsheet Builder transforms the landscape of textile printing and elevates the standard for print quality.

In the fast-paced realm of fabric printing, the emergence of the Gangsheet Builder for Direct-To-Film (DTF) applications represents a significant technological breakthrough. This innovative approach not only simplifies the printing process but also allows for the simultaneous transfer of multiple graphics onto various textiles, proving to be a game-changer compared to classic screen printing techniques. By leveraging modern textile printing technology, businesses can achieve expansive print production efficiency while still maintaining high quality and affordability in their outputs. As demand for personalized apparel escalates, understanding the capabilities of DTF and the Gangsheet Builder becomes crucial for companies aiming to remain competitive in the marketplace. Embrace this evolution in print methodologies to harness the full potential of your textile creations.

Exploring the Efficiency of DTF Gangsheet Builder

The DTF Gangsheet Builder revolutionizes the production efficiency in textile printing by enabling multiple designs to be printed simultaneously on a single sheet. This method significantly reduces setup times compared to traditional screen printing, where each design typically requires a painstakingly separate setup process. In today’s fast-paced industry, the ability to quickly produce high-quality outputs without sacrificing time is invaluable for print shops aiming to meet client demands and increase their market share.

Furthermore, the efficiency gained through the DTF Gangsheet Builder isn’t just about speeding up production; it also minimizes waste both in materials and labor. In traditional screen printing, greater material waste often occurs due to the setup and cleanup processes associated with individual print runs. With DTF technology, print shops benefit from better print production efficiency, allowing them to utilize resources more effectively, thus leading to a more sustainable printing practice.

High-Quality Print Outcomes with DTF Methods

Quality is a paramount concern in textile printing, and DTF printing excels in this area by offering vibrant colors and exceptional durability. DTF Gangsheet Builders enhance this quality by ensuring that designs are transferred with high fidelity onto various fabric types, maintaining clarity and detail in every print. This flexibility means that businesses can cater to a broader range of customer requirements, from cotton to polyester and blends, without compromising on quality.

Unlike traditional printing methods, which may face limits in ink adhesion and color fidelity, the DTF technique provides prints that can endure multiple washes without fading or cracking. This quality assurance leads not only to greater customer satisfaction but also to repeat business and referrals, as consumers are more likely to return for products that consistently meet or exceed expectations.

Cost-Effectiveness of DTF Printing

Cost constraints are a critical factor for many printing businesses, particularly those targeting small orders or custom jobs. The DTF Gangsheet Builder presents a cost-effective alternative to traditional screen printing, which often involves substantial initial setup costs for multi-color designs. By streamlining the printing process, DTF helps reduce overheads, enabling smaller entities to thrive and compete in a market increasingly driven by customization.

Moreover, the cost benefits extend beyond initial setups, as the reduced need for extensive materials and labor translates to lower overall production costs. With DTF technology, print shops can execute short runs more economically, making it a suitable choice not only for established businesses but also for freelancers and startups looking to enter the customization market without facing exorbitant pricing barriers.

User-Friendliness of Modern DTF Tools

One of the remarkable features of contemporary DTF Gangsheet Builders is their user-friendly design, which facilitates ease of access to high-quality print production. Many of these systems include intuitive software that simplifies the design layout process, enabling even those without extensive technical expertise to contribute effectively. This democratization of access allows more individuals to participate in textile printing, which widens the talent pool within the industry.

In contrast, traditional printing methods often require specialized training and technical skills, creating barriers for new entrants. The simplified interface and automation found in modern DTF systems mean that businesses can onboard new employees much more quickly, enhancing operational efficiency and enabling teams to focus on creativity and design rather than navigating complex machinery.

Industrial Adoption of DTF Technology

The industrial landscape for textile printing is rapidly changing, with many companies now shifting towards DTF methods due to their outstanding performance and versatility. The DTF Gangsheet Builder has been instrumental in this transition, allowing businesses to improve production output while maintaining high standards of quality. As more apparel brands adopt this technology, the demand for skilled professionals in DTF printing continues to rise, creating new job opportunities within the industry.

This shift towards DTF printing also aligns with broader trends in consumer preferences, where customization and high-quality products are in high demand. Industries are increasingly recognizing that adopting innovative printing technologies is essential not just for keeping pace but also for positioning themselves as leaders in quality and efficiency.

The Future of Textile Printing with DTF Innovations

As we look to the future of textile printing, innovations such as the DTF Gangsheet Builder are setting new benchmarks for quality, efficiency, and sustainability. Businesses that embrace these technologies are not just adapting but are likely to thrive in an increasingly competitive landscape. By leveraging the advantages of DTF printing, companies can cater to diverse customer needs while experiencing positive growth due to reduced costs and enhanced production capabilities.

In conclusion, the incorporation of DTF technology into printing operations represents a pivotal shift towards the future. As print shops continue to explore innovative solutions, it becomes evident that traditional methods may soon be overshadowed by the benefits of DTF. Hence, businesses that actively engage in these technologies will be better positioned to meet the demands of evolving markets and consumer trends.

Frequently Asked Questions

What is DTF Gangsheet Builder and how does it improve print production efficiency?

DTF Gangsheet Builder is a tool that enables users to print multiple designs on a single film sheet, significantly enhancing print production efficiency. By consolidating designs, it reduces setup time and minimizes material waste, making it faster and more cost-effective than traditional screen printing methods.

How does DTF printing differ from screen printing in terms of quality?

DTF printing generally offers superior quality compared to screen printing. It allows for high-fidelity reproductions with vibrant colors that adhere well to various fabric types. DTF prints withstand washing without fading, ensuring long-lasting quality that is particularly beneficial for consumer satisfaction.

What are the cost advantages of using a DTF Gangsheet Builder over traditional printing methods?

Using a DTF Gangsheet Builder is more cost-effective than traditional methods like screen printing because it involves lower setup fees, especially for multi-color jobs. This advantage allows businesses, especially smaller ones, to produce high-quality prints in shorter runs without incurring high costs.

Is DTF printing technology versatile when it comes to different fabric types?

Yes, DTF printing technology is highly versatile, compatible with a wide range of fabrics, including cotton, polyester, and blends. This flexibility exceeds that of many traditional printing methods, which may only work on specific materials. The DTF Gangsheet Builder enhances this capability by allowing diverse designs on one sheet.

What makes DTF Gangsheet Builder user-friendly compared to traditional printing techniques?

DTF Gangsheet Builders typically feature intuitive software that simplifies the design layout process, making it accessible even for those without technical backgrounds. In contrast, traditional printing techniques, like screen printing, often require specialized skills and training, making it more daunting for newcomers.

How has the introduction of DTF printing changed the landscape for textile printing technology?

The introduction of DTF printing and tools like the DTF Gangsheet Builder has revolutionized textile printing technology by providing quick, effective, and high-quality outputs. This shift allows print shops to meet growing demands for customization and personalization while maintaining efficiency and cost-effectiveness, marking a significant advancement over traditional methods.

| Key Points | DTF Gangsheet Builder | Traditional Methods |

|---|---|---|

| Efficiency | Allows multiple designs to be printed simultaneously, streamlining production and minimizing waste. | Requires separate setups for each design, consuming more time and resources. |

| Quality | Produces vibrant colors and durable prints that withstand multiple washes. | May lack flexibility in fabric compatibility, resulting in varied quality on different materials. |

| Cost-Effectiveness | Lower setup costs, making it ideal for small businesses and short runs. | High setup costs, particularly for multi-color jobs, making it less economical for low-volume jobs. |

| Ease of Use | User-friendly software enables accessibility for individuals without extensive technical skills. | Requires specialized knowledge and skills, which can be intimidating for newcomers. |

Summary

DTF Gangsheet Builder represents a revolutionary advancement in textile printing. By leveraging this innovative technology, print shops can enhance their efficiency, deliver superior quality prints, and reduce operational costs. Unlike traditional methods such as screen printing, which often involve high setup costs and complex procedures, the DTF approach simplifies the production process, enabling quick turnarounds for diverse design needs. As the industry continues to embrace these changes, adopting the DTF Gangsheet Builder not only meets growing demand but also positions businesses for future success in a rapidly evolving market.