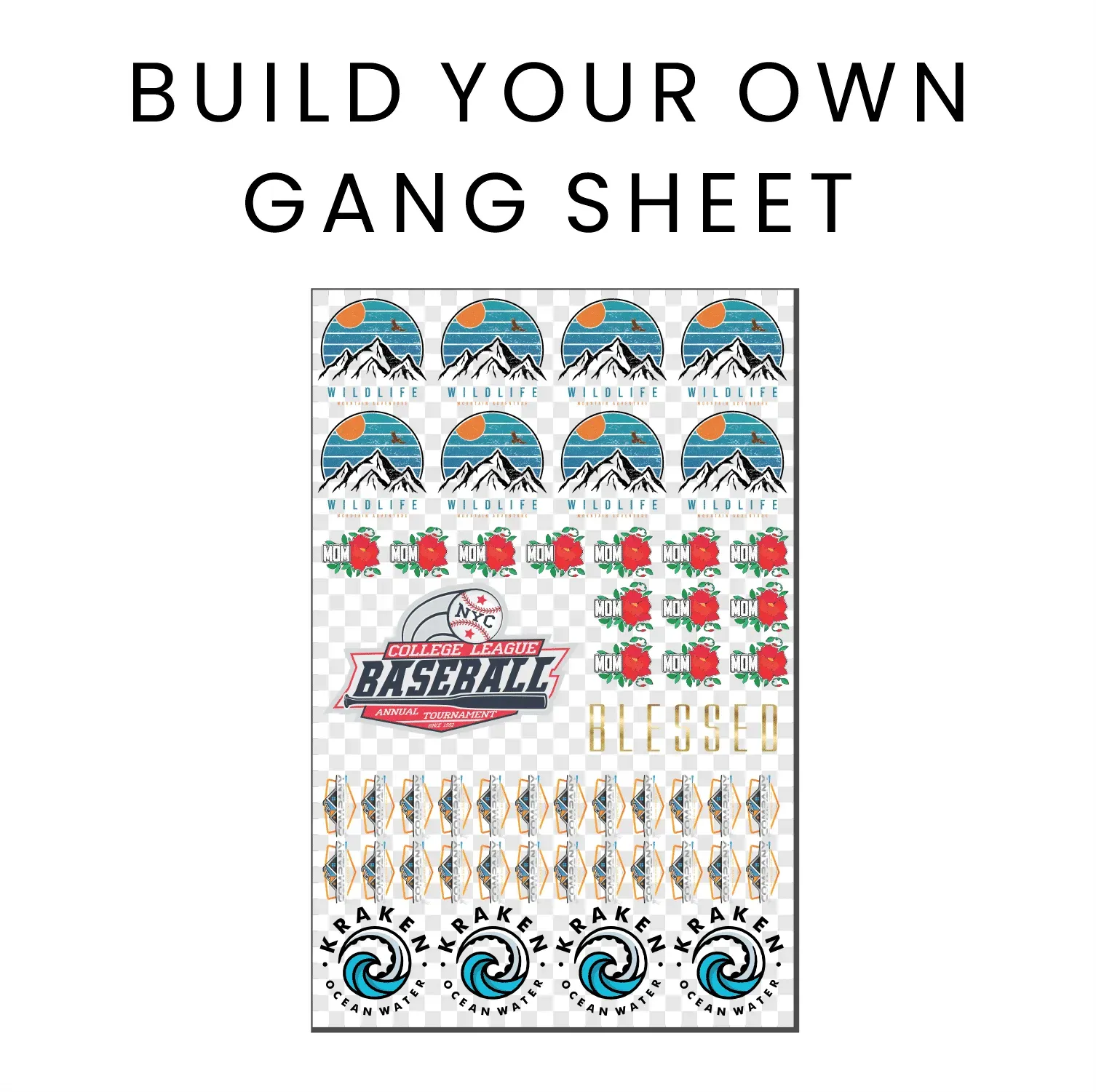

The DTF Gangsheet Builder is revolutionizing the textile printing landscape with its innovative approach to Direct-to-Film printing. As traditional printing methods, such as screen printing, face challenges in efficiency and versatility, the DTF Gangsheet Builder emerges as a preferred solution for businesses seeking to optimize printing processes. This cutting-edge technology allows multiple designs to be printed seamlessly on a single sheet, significantly reducing material waste and enhancing overall printing efficiency. With the ability to produce vibrant, complex designs, the DTF Gangsheet Builder caters to the growing demand for custom apparel, making it an indispensable tool for modern print shops. In this article, we will explore the advantages and disadvantages of DTF printing compared to traditional methods to guide businesses in their printing decisions.

The evolution of textile printing technology has opened new avenues for businesses looking to enhance their production capabilities. Alternative concepts to the DTF Gangsheet Builder include traditional screen printing methods, which have long dominated the industry due to their cost-effective high-volume production. However, as the demand for intricate designs and quick turnaround times rises, innovative solutions like DTF printing are becoming increasingly relevant. This discussion will provide insight into the benefits and limitations of both DTF technology and conventional printing methods, helping companies to weigh their options in line with their operational needs.

Comparing DTF Gangsheet Builders with Screen Printing

The DTF Gangsheet Builder represents a significant shift in the textile printing landscape, particularly in comparison to traditional screen printing methods. While screen printing has long been the preferred choice for large production runs due to its speed and efficacy, DTF printing introduces a dynamic alternative that focuses on flexibility and creative design capabilities. This modern technique allows for multiple designs to be printed in a single pass, reducing waste and maximizing resources, making it particularly attractive for smaller operations or shops looking to diversify their offerings.

In contrast, screen printing requires set-up for each individual design and color, which can lead to longer turn-around times and higher costs per print for smaller batches. The DTF Gangsheet Builder thus caters effectively to businesses that prioritize high-quality prints in a timely manner, enabling them to fulfill custom orders efficiently. As digital textile printing technology continues to advance, understanding these differences is crucial for businesses aiming to stay competitive in the printing market.

Advantages of DTF Printing Technology

One of the standout benefits of DTF printing technology, particularly with tools like the DTF Gangsheet Builder, is its cost-effectiveness for short runs. By allowing for the printing of multiple designs on a single sheet, businesses can significantly cut down on material usage and waste, which ultimately lowers production costs. This reduction in costs combined with the ability to produce vibrant, full-color designs makes DTF an attractive option for brands wanting to cater to a variety of customer tastes without incurring high overhead.

Moreover, DTF printing facilitates a quicker turnaround, crucial for businesses that operate under tight deadlines. In an industry where timing is paramount, the efficient set-up required for DTF printing technology means that orders can be processed much faster than with traditional methods, which often include lengthy setup times for each individual screen. This agility supports businesses in maintaining high levels of customer satisfaction and responsiveness in a competitive market.

Challenges of DTF Gangsheet Builders

Despite the many benefits, employing DTF Gangsheet Builders does come with certain challenges. One significant concern for users is the durability of the prints. While DTF printing has made strides in improving the lifespan of designs on fabric, some users have reported issues, particularly regarding heavy washing or wear. This raises important considerations for businesses in selecting the right inks and ensuring proper application techniques to enhance durability.

Additionally, the initial investment in DTF equipment can pose a hurdle, particularly for smaller entities or new businesses seeking to enter the textile printing market. The costs associated with setting up a reliable DTF printing operation, including printer cost, inks, and substrate, may discourage potential adopters despite the long-term benefits associated with increased efficiency and product quality.

Pros of Traditional Screen Printing

Screen printing has earned its reputation as a reliable and cost-effective method for high-volume print runs. The established techniques have been optimized over the years, making this method particularly appealing for businesses that require consistency and quality across large orders. This reliability in print quality, coupled with the reasonable cost per unit for large batches, makes screen printing a mainstay in the textile industry.

Moreover, the technical familiarity and established processes in screen printing can be advantageous for traditional businesses that are reluctant to adopt newer technologies. Particularly for companies that focus on simpler designs, screen printing may still offer the best balance of efficiency and outcomes.

Drawbacks of Traditional Printing Methods

While screen printing excels in numerous areas, it is not without its drawbacks, particularly when it comes to setup times and design limitations. The method requires a screen to be created for each color in the design, which can make the workflow sluggish for multi-color or intricate designs. As a result, businesses can find themselves facing steep delays whenever complex orders come in.

Furthermore, traditional methods can sometimes limit the types of designs that can be produced efficiently. Intricate graphics that incorporate gradients and multiple colors can struggle to be reproduced accurately, which can hinder creative possibilities for print designers looking to push the boundaries of textile printing.

Choosing the Right Printing Method for Your Needs

When deciding between DTF Gangsheet Builders and traditional methods, businesses must carefully assess their unique needs in the context of order volume, desired design complexity, and turnaround times. For companies focused on small to medium runs with an emphasis on creativity, DTF printing may offer the versatility and efficiency necessary to thrive in a competitive marketplace.

Conversely, businesses entrenched in high-volume production may find that traditional screen printing remains the more cost-effective choice due to its proven methodologies for mass output. By evaluating their specific goals and constraints, companies can make informed choices about which printing technology aligns best with their operational needs and objectives.

Frequently Asked Questions

What are the advantages of using the DTF Gangsheet Builder over traditional printing methods?

The DTF Gangsheet Builder provides several advantages over traditional printing methods like screen printing, including reduced material waste, improved printing efficiency, and the ability to produce vibrant, intricate designs on various fabrics. This cost-effective solution is especially beneficial for small to medium-sized orders, allowing businesses to optimize their resources and respond quickly to market demands.

How does DTF Printing compare to traditional screen printing in terms of printing efficiency?

DTF Printing, particularly with the DTF Gangsheet Builder, excels in printing efficiency compared to traditional screen printing. It allows multiple designs to be printed simultaneously on a single sheet, minimizing setup times and material waste while delivering high-quality prints that meet diverse customer needs.

Is DTF Gangsheet Builder a cost-effective solution for small printing businesses?

Yes, the DTF Gangsheet Builder is a highly cost-effective solution for small printing businesses. It reduces the cost per print by maximizing material use and minimizing waste, making it an ideal option for businesses that handle small to medium-sized orders without sacrificing quality.

What types of designs can be produced with DTF Gangsheet Builder and how do they compare to traditional printing methods?

The DTF Gangsheet Builder is capable of producing complex and colorful designs that may be challenging with traditional printing methods like screen printing, which often face limitations in intricacy. This versatility enables businesses to cater to a wider variety of customer preferences, enhancing market competitiveness.

Are there any durability concerns with prints made using the DTF Gangsheet Builder compared to traditional methods?

While DTF prints created with the Gangsheet Builder have improved significantly, some users report durability issues, especially with heavy washing. It’s crucial for businesses to ensure proper curing of inks to enhance longevity, as traditional methods like screen printing are often recognized for their reliability and durability.

What considerations should businesses make when choosing between DTF Gangsheet Builder and traditional printing methods?

When deciding between DTF Gangsheet Builder and traditional printing methods, businesses should consider factors such as order volume, design complexity, initial investment costs, and required turnaround times. DTF technology is suited for those seeking innovation and efficiency, while traditional methods may benefit high-volume operations focused on reliability.

| Aspect | DTF Gangsheet Builder | Traditional Methods (Screen Printing) |

|---|---|---|

| Cost Effectiveness | Reduces cost per print, ideal for small runs | More cost-effective for large volumes, but higher setup costs for smaller runs |

| Design Versatility | Allows intricate and colorful designs on various fabrics | Best for simpler designs, struggles with complexities |

| Setup and Turnaround | Simpler setup with quicker response times | Longer setup times especially for multi-color designs |

| Durability | Print longevity can be a concern; requires careful curing | Proven durability but limited by design complexities |

| Investment | Higher initial investment may deter small businesses | Established method with lower financial barriers for setup |

Summary

DTF Gangsheet Builder offers a modern solution for businesses looking to enhance their printing capabilities. This innovative approach allows multiple designs to be printed simultaneously, optimizing efficiency and reducing waste. In contrast to traditional methods, DTF technology provides remarkable versatility in design and quicker turnaround times. As competition in the textile industry intensifies, adopting the DTF Gangsheet Builder equips businesses with the ability to meet diverse customer needs swiftly and effectively. By evaluating their specific requirements, companies can leverage the strengths of DTF technology for greater profitability and customer satisfaction.