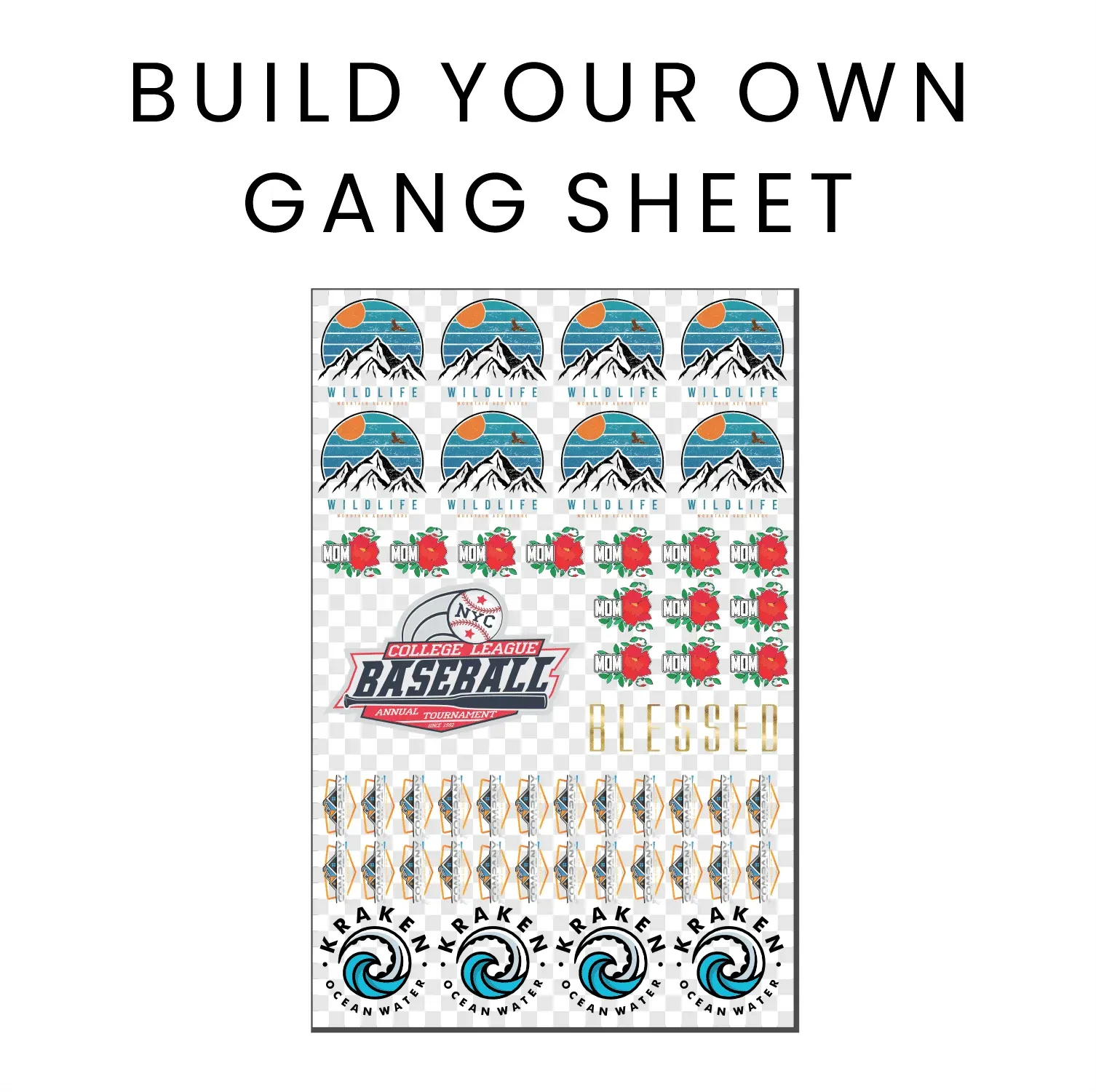

DTF gangsheet builders represent a transformative breakthrough in the landscape of Direct-to-Film (DTF) printing technology, which has swiftly gained traction in the apparel and textile sectors. By leveraging these innovative builders, printers can maximize output while experiencing substantial cost reductions, a significant advantage for businesses aiming to stay competitive. Gangsheet printing enhances the workflow by allowing multiple designs to be printed concurrently on a single sheet, making it an efficient printing technology that optimizes ink usage and minimizes waste. Beyond the immediate financial benefits, these builders also support sustainable printing solutions, aligning with the increasing consumer demand for environmentally friendly practices. In the context of DTF printing market trends, understanding how to effectively utilize DTF gangsheet builders can be a game-changer for both new and established printing enterprises.

Exploring the advancements in Direct-to-Film printing systems, particularly those utilizing gangsheet techniques, reveals a wealth of potential for innovation. These systems enable printers to produce high-quality prints with remarkable efficiency, showcasing how modern printing technology is evolving. By employing gangsheet methodologies, businesses can streamline their operations and improve profitability while also addressing sustainability concerns. The rise of eco-conscious consumer preferences has led to a growing interest in sustainable printing solutions, further underscoring the importance of effective gangsheet builders. Understanding these alternative terms and concepts can provide deeper insights into the DTF landscape and its implications for the future of textile printing.

Understanding DTF Printing Technology

Direct-to-Film (DTF) printing technology has emerged as a game changer in both apparel and textile industries. This innovative method allows designs to be printed directly onto a special film, which is later transferred onto fabric using heat. Unlike traditional methods, DTF is not only versatile but also caters to a wide range of materials, from cotton to polyester blends, making it ideal for customized prints. Its ability to produce vibrant colors and intricate details sets it apart, making it a popular choice among printers and designers alike.

Furthermore, DTF printing excels in quick turnaround times, a crucial factor in today’s fast-paced market. The technology’s efficiency allows for swift production without compromising on quality. As businesses increasingly demand speed and flexibility, DTF printing meets these needs effectively, illustrating why this technology is quickly gaining traction in the industry.

The Role of DTF Gangsheets in Cost Management

DTF gangsheet builders play an essential role in managing costs for printing businesses. By allowing multiple designs to be printed on a single sheet, gangsheet printing optimizes ink usage while minimizing material waste. This translates to significant savings on production costs, as businesses can produce more in less time and with fewer resources. With leading-edge gangsheet technology, printers can manage their expenses better and consequently improve their profit margins.

Moreover, integrating efficient DTF gangsheet builders into production workflows can streamline operations, allowing businesses to allocate their resources more effectively. The ability to handle multiple designs simultaneously not only increases output but also reduces the need for excessive inventory, further driving down costs. In an industry where margin improvement is critical, these benefits cannot be overlooked.

One of the most significant advantages is the reduced ink consumption due to careful arrangement of designs. Modern DTF gangsheet builders come with features that ensure optimal layout and spacing, maximizing every inch of the sheet to prevent wastage. By investing in these advanced solutions, printers can achieve high volumes of quality prints without overspending.

Ultimately, leveraging DTF gangsheet printing allows companies to maintain a competitive edge in an increasingly cost-sensitive market, encouraging them to adopt this efficient approach to stay profitable.

Innovative Software Enhancing DTF Printing

Recent advancements in software technology have significantly enhanced the functionality of DTF gangsheet builders. With cutting-edge software, features such as automatic design nesting and scaling adjustments have simplified the workflow for printing businesses. These innovations reduce production times and enhance inventory management, allowing for a seamless operational experience. Efficient software solutions mean that designs can be optimized for space on the gangsheet, ensuring minimal waste and maximum productivity.

Companies like CADlink and Wasatch lead the way in software innovation tailored specifically for the DTF printing process. Their user-friendly interfaces combined with powerful nesting algorithms empower printers to maximize their output while minimizing manual effort. This means quicker turnarounds and the ability to handle larger orders efficiently, providing businesses with a robust tool for meeting customer demand and keeping pace with industry growth.

Elevating Print Quality with DTF Technology

Alongside efficiency benefits, the evolution of DTF gangsheet builders has significantly enhanced print quality in the industry. Modern DTF printers are equipped with advanced print heads and high-quality ink formulations that produce stunning color vibrancy and exceptional durability. This improvement in print technology ensures that customers receive high-quality products that stand the test of time, leading to increased customer satisfaction and repeat orders.

Moreover, the combination of DTF printing and gangsheet builders helps businesses stay competitive by improving the consistency of print quality across multiple design runs. Enhanced print quality not only elevates brand reputation but also attracts a more discerning clientele who may be willing to pay a premium for superior products. As businesses get feedback from their customers regarding quality improvements, they realize that investing in superior DTF technology pays dividends through customer loyalty and positive word-of-mouth.

Sustainable Practices in DTF Printing

In an age where consumers are increasingly focused on sustainability, efficient DTF gangsheet builders contribute significantly to eco-friendly printing initiatives. The integration of sustainable materials and eco-conscious inks in the DTF process aligns with the growing demand for responsible consumption. By adopting these green practices, businesses not only cater to a market segment that values sustainability but also reduce their ecological footprint.

DTF gangsheet builders enable printers to produce high-quality prints while utilizing eco-friendly resources effectively. The ability to reduce material waste and optimize ink usage reflects a commitment to sustainable practices. As the printing industry continues to evolve, embracing eco-friendly DTF solutions positions businesses to thrive while meeting consumer demands for greater environmental responsibility.

Current Trends in the DTF Printing Market

The DTF printing market is experiencing robust growth, driven by emerging trends in customization and consumer demand for personalized apparel. With advancements in DTF technology, businesses are discovering that efficient gangsheet printing allows for greater customization options, catering to a diverse range of customer preferences. This trend is paving the way for innovative printing solutions that accommodate varying orders, from small batches to large-scale productions.

As more businesses recognize the benefits of DTF printing, the integration of efficient gangsheet builders becomes essential. These builders not only enable the printing of multiple designs on a single sheet but also enhance operational efficiency, allowing companies to respond quickly to customer requests. Industry insiders predict that as consumer engagement rises with personalized products, companies that utilize advanced DTF gangsheet technology will lead the way in the market.

Frequently Asked Questions

What are DTF gangsheet builders and how do they enhance Direct-to-Film printing?

DTF gangsheet builders are specialized tools that optimize Direct-to-Film printing by allowing multiple designs to be printed on a single sheet. This efficiency reduces material waste and lowers costs, making them essential for businesses looking to enhance their printing operations.

What are the key benefits of using DTF gangsheet builders for efficient printing technology?

The key benefits of DTF gangsheet builders include improved efficiency through reduced ink usage and minimized film wastage. They enable businesses to print multiple designs simultaneously, which leads to significant cost savings and increased profit margins.

How do software innovations impact the performance of DTF gangsheet builders?

Software innovations enhance the performance of DTF gangsheet builders by incorporating features like automatic design nesting and scalable adjustments. These updates allow for quicker production and better inventory management, improving overall efficiency in the DTF printing process.

In what ways do DTF gangsheet builders contribute to sustainable printing solutions?

DTF gangsheet builders contribute to sustainable printing solutions by facilitating the use of eco-friendly inks and sustainable materials. This aligns with the growing demand for environmentally friendly printing practices, helping businesses lower their ecological impact.

What are the current market trends in the DTF printing industry concerning gangsheet builders?

Current market trends in the DTF printing industry show a significant rise in demand for customizable apparel. Efficient DTF gangsheet builders are critical in meeting this demand, allowing businesses to provide personalized options while enhancing customer engagement.

How can adopting efficient DTF gangsheet builders improve print quality?

Adopting efficient DTF gangsheet builders improves print quality by leveraging advanced DTF printers equipped with better print heads and ink compositions. This leads to vibrant colors and durable prints, ensuring customer satisfaction and promoting repeat business.

| Key Points | Details |

|---|---|

| 1. Efficiency and Cost-Effectiveness | Optimizes ink usage and reduces material wastage, leading to cost savings and increased profit margins for businesses. |

| 2. Software Innovation | Advancements like automatic nesting and scaling adjustments allow quicker production and better inventory management. Companies such as CADlink and Wasatch lead in developing user-friendly software for this purpose. |

| 3. Print Quality Improvements | Modern DTF printers combined with advanced gangsheet builders result in vibrant colors and durable prints, contributing to customer satisfaction and repeat business. |

| 4. Sustainability | Integration of eco-friendly practices, including green inks and sustainable materials, aligns with consumer preferences, reducing the ecological footprint of printing businesses. |

| 5. Market Trends | Growing recognition of DTF printing benefits leads to increased demand for customizable apparel, with efficient gangsheet builders essential for meeting consumer expectations. |

Summary

DTF gangsheet builders are revolutionizing the printing industry by enhancing efficiency, print quality, and sustainable practices. By leveraging modern technology and software innovations, businesses can significantly cut costs while producing high-quality prints that meet consumer demand. This alignment with environmentally friendly practices not only appeals to a broader audience but also helps printing companies contribute to a healthier industry. To stay competitive, it’s imperative for businesses to embrace DTF gangsheet builders, maximizing their production capabilities and ensuring sustainable growth in a rapidly evolving market.