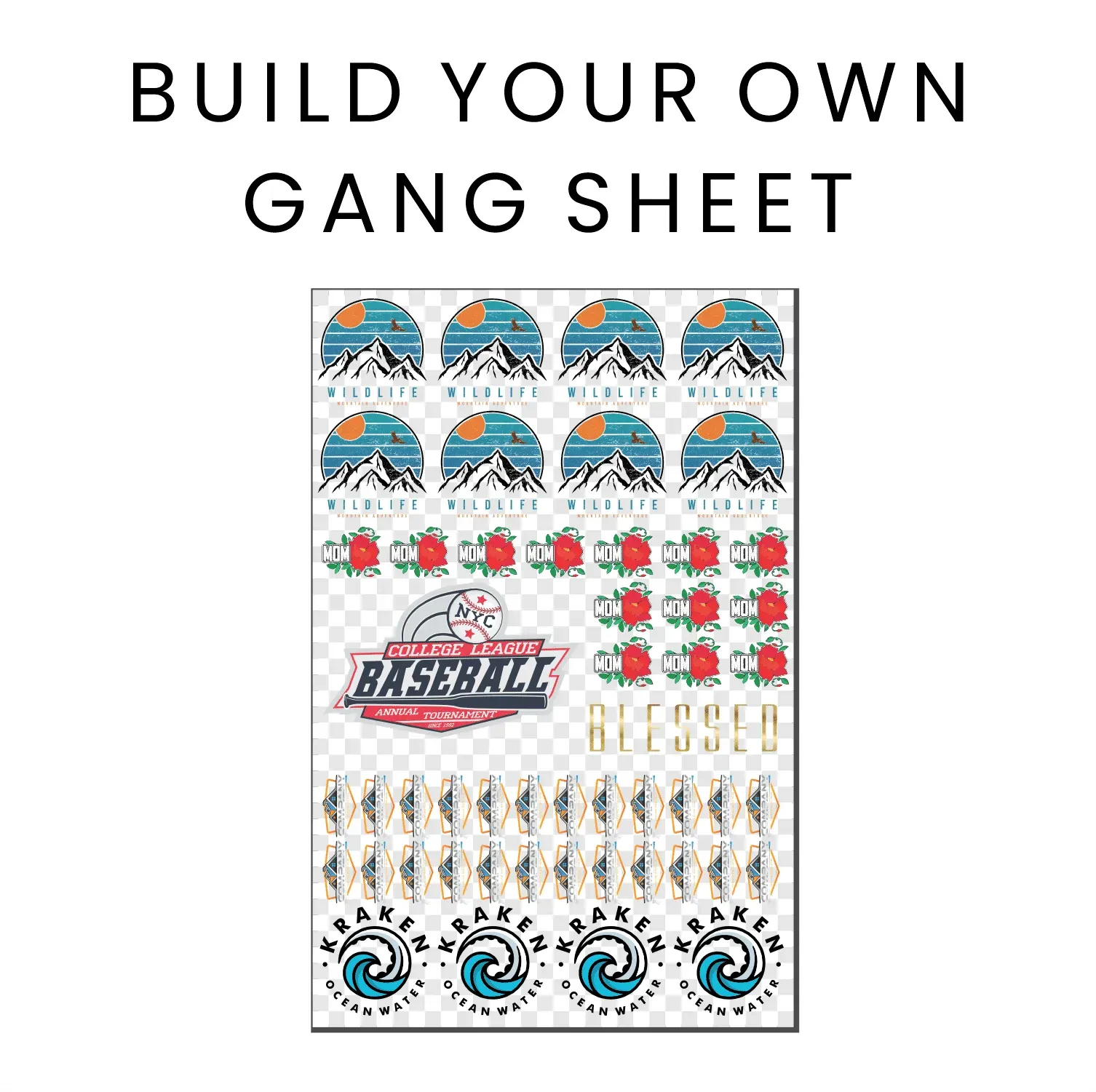

In the fast-evolving realm of custom printing, **DTF Gangsheet Builders** represent a groundbreaking advancement, streamlining the process of applying high-quality designs using Direct to Film printing technology. By leveraging gangsheet printing, these tools enable designers and businesses to efficiently merge multiple designs onto a single film sheet, promoting material optimization and cost-effectiveness. The power of DTF software tools amplifies this process, making it easier to create intricate designs that stand out on various fabrics. As the DTF printing revolution gains momentum, understanding the capabilities of DTF Gangsheet Builders becomes essential for those looking to innovate in custom printing solutions. This guide aims to illuminate the diverse benefits and opportunities presented by these remarkable tools, paving the way for more efficient and vibrant prints.

Exploring the world of **Direct to Film (DTF)** technology reveal a dynamic landscape where innovations, such as **gangsheet builders**, are transforming the custom printing industry. Known for their versatility and efficiency, these tools allow users to assemble multiple designs into a single layout, streamlining the printing process. This strategic arrangement not only conserves resources but also enhances productivity, making it easier for businesses to meet their printing demands. As the popularity of **DTF printing** continues to rise, embracing effective tools and methodologies is crucial for anyone involved in fabric printing. The integration of advanced **DTF software tools** into this process further empowers users to develop bespoke printing solutions that cater to unique customer needs.

Exploring the Benefits of DTF Printing

DTF printing offers numerous advantages over traditional fabric printing methods, making it a popular choice for many businesses. One key benefit is its flexibility; DTF can produce vibrant designs on a wide array of fabric types, including cotton, polyester, and blends. This flexibility allows companies to cater to diverse client requests, providing high-quality, colorful outputs that stand out in the competitive market of custom apparel.

Moreover, the DTF printing process enables faster production times compared to other printing techniques. The ability to print intricate designs quickly means businesses can meet tight deadlines without sacrificing quality. Whether for a small batch of custom t-shirts or a large-scale promotional campaign, DTF printing technology ensures that products can be delivered promptly, enhancing customer satisfaction and driving repeat business.

Understanding DTF Gangsheet Builders

DTF Gangsheet Builders simplify the process of producing multiple designs on a single film sheet, which not only enhances productivity but also optimizes material usage. This technological advancement is essential for businesses looking to minimize waste in their operations. By consolidating various prints into one sheet, companies can reduce the number of film sheets required, thus lowering overall printing costs while still delivering diverse design options.

Furthermore, these tools provide an intuitive interface for users, allowing even those new to DTF printing to efficiently create gang sheets. As users become more familiar with the process, they can experiment with layout designs, maximizing space, and ensuring all prints are perfectly positioned for optimal quality. This capability makes DTF Gangsheet Builders indispensable for anyone serious about custom printing solutions.

The Cost-Effective Advantage of DTF Printing

One of the standout features of DTF printing is its cost-effectiveness. By significantly reducing material waste through the use of gang sheets, businesses can achieve substantial savings on ink and film. This is especially beneficial for startups and small businesses operating on tight budgets, as it allows them to maximize profits while providing high-quality printed products.

In addition to saving on materials, DTF printing accelerates turnaround times. Since gang sheet building streamlines the design process, businesses can produce multiple designs in one go, enhancing workflow efficiency. This not only reduces production time but allows for quick fulfillment of large orders, making DTF printing an attractive option for businesses facing demanding timelines.

Harnessing DTF Software Tools for Excellence

Embracing powerful DTF software tools like Roland VersaWorks 6 and CADlink Digital Factory can enhance the printing process, resulting in superior print quality and efficiency. These programs offer features tailored to DTF printing, such as advanced color management and layout optimization, allowing users to bring their creative visions to life with precision.

Using DTF software effectively means that users can fine-tune their prints according to specific fabric types and colors. This customization capability helps ensure that designs appear vibrant and true to the original artwork, regardless of the medium. Consequently, investing in the right software tools can yield significant improvements in both the quality of outputs and overall customer satisfaction.

Trends Shaping the Future of DTF Printing

The DTF printing market is constantly evolving, with new trends influencing how businesses approach custom printing. One notable trend is the growing availability of affordable DTF printers and supplies, which is lowering the barriers to entry for new entrepreneurs seeking to join the industry. This influx of products not only stimulates competition but also leads to innovations that enhance the capabilities of DTF technology.

Another pivotal trend is the increasing focus on sustainability. Manufacturers are exploring eco-friendly inks and materials, catering to the rising demand for environmentally responsible products. As consumers become more conscious of their purchasing decisions, businesses adopting sustainable practices in DTF printing can differentiate themselves in a crowded marketplace, appealing to eco-aware customers.

Educational Resources for Mastering DTF Printing

Maximizing the potential of DTF Gangsheet Builders requires a commitment to continuous learning. Numerous online resources, including tutorials on YouTube and specialized printing blogs, provide valuable insights into DTF software tools and techniques. These educational platforms cover everything from basic setup tips to advanced printing strategies, helping users refine their skills and improve their output quality.

Engaging with fellow printing enthusiasts and professionals through online forums can also be beneficial. Participation in discussions and collaborative projects can lead to shared knowledge and innovative techniques. By tapping into these educational resources, printing businesses can stay informed about the latest developments in DTF technology and enhance their operations.

Frequently Asked Questions

What is a DTF Gangsheet Builder?

A DTF Gangsheet Builder is a tool used in Direct to Film (DTF) printing that allows users to arrange multiple designs on a single film sheet. This maximizes printing efficiency, reduces material waste, and helps lower overall printing costs while maintaining high design quality.

How does DTF printing technology benefit custom printing solutions?

DTF printing technology enhances custom printing solutions by allowing high-quality, vibrant designs to be transferred onto various fabrics. It provides flexibility for users to produce intricate and colorful prints suitable for both individual projects and bulk orders.

What are the key advantages of using DTF Gangsheet Builders in production?

Using DTF Gangsheet Builders offers several advantages, including customization and versatility in print sizes, cost-effectiveness due to reduced material waste, and the ability to produce high-quality outputs that remain vibrant over time on both light and dark fabrics.

What software tools are recommended for using DTF Gangsheet Builders?

Popular software tools for DTF Gangsheet Builders include Roland VersaWorks 6 and CADlink Digital Factory. These programs streamline the design process of gang sheets and enhance user efficiency by providing features tailored for DTF printing.

Can DTF Gangsheet Builders help reduce printing costs?

Yes, DTF Gangsheet Builders help reduce printing costs by minimizing material waste. By printing multiple designs on a single sheet, businesses save on ink and film while also speeding up the workflow necessary for meeting tight deadlines.

What trends are emerging in DTF printing technology?

Emerging trends in DTF printing technology include an increase in eco-friendly materials and inks, responsive to the growing demand for sustainable practices, and the introduction of innovative, cost-effective products aimed at making DTF printing accessible to small businesses and entrepreneurs.

| Key Point | Description |

|---|---|

| DTF Technology | Direct to Film (DTF) printing transfers designs onto fabric using an adhesive for durability and vibrancy. |

| DTF Gangsheet Builders | These tools allow multiple designs to be printed on a single film sheet, enhancing productivity and reducing costs. |

| Customization and Versatility | Users can easily adjust sizes and designs, making them ideal for both individual and bulk orders. |

| Cost-Effectiveness | Minimizing material waste while maximizing output leads to significant savings on ink, film, and time. |

| High-Quality Outputs | Advanced ink formulations provide bright colors and sharp images suitable for various fabrics. |

| Notable Software Tools | Roland VersaWorks 6 and CADlink Digital Factory simplify the process of creating gang sheets and maximize print area. |

| Trends in DTF Printing | Emerging products and a focus on sustainability are making DTF printing more accessible and environmentally friendly. |

| Educational Resources | Online tutorials and blogs offer valuable insights and tips for mastering DTF printing techniques. |

Summary

DTF Gangsheet Builders are revolutionizing the custom printing industry, providing essential tools that enhance efficiency, customization, and quality in print production. These builders allow users to consolidate multiple designs onto a single film sheet, significantly cutting down on wasted material and costs—making them a vital asset for businesses aiming to streamline their printing processes. As the DTF printing technology continues to evolve, the importance of staying informed about the latest trends, software tools, and sustainable practices becomes more critical. By leveraging the capabilities of DTF Gangsheet Builders, users can optimize their production workflows and achieve stunning results, ensuring they remain competitive in this dynamic market.