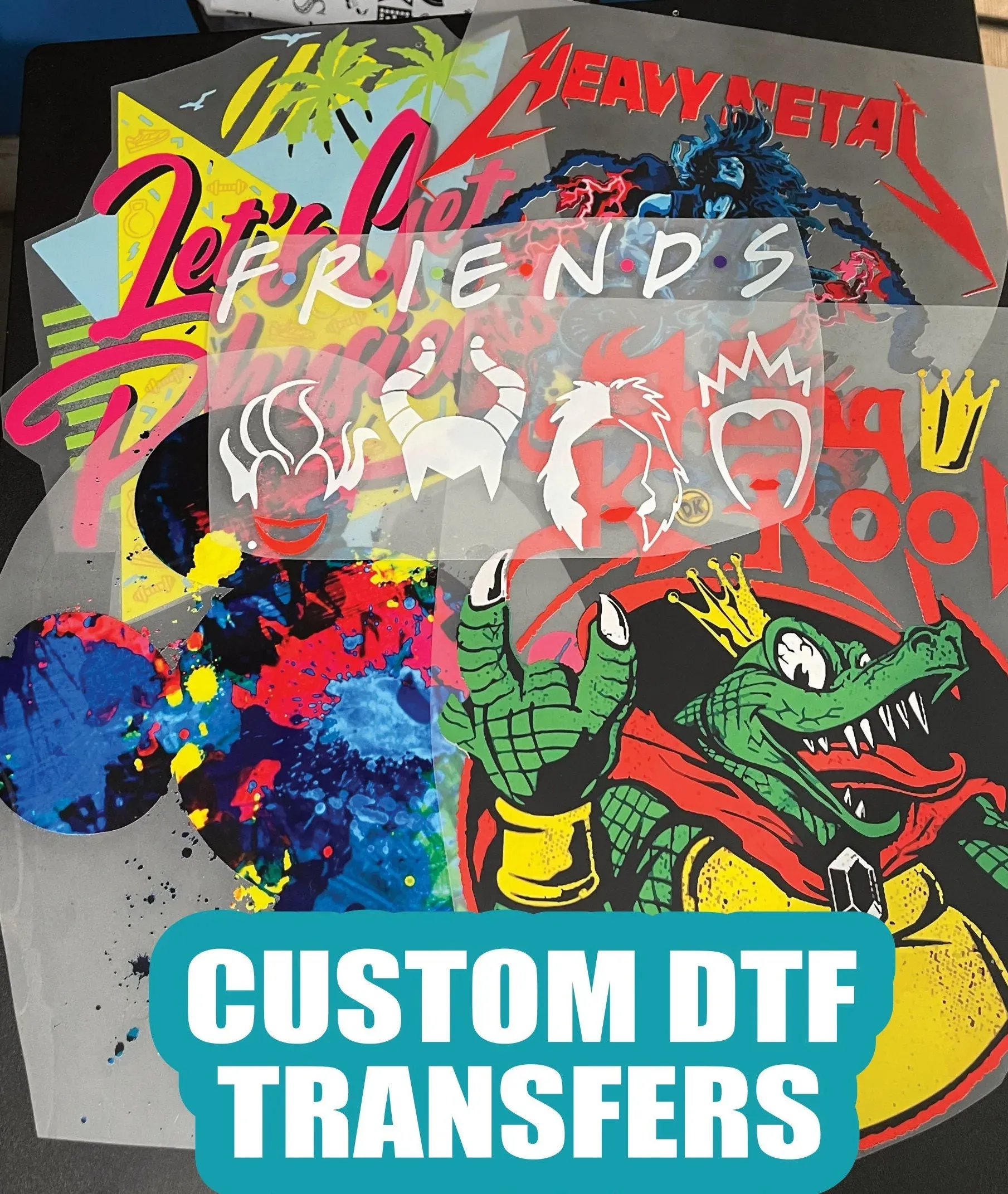

In the ever-evolving realm of fabric printing methods, **DTF Transfers** (Direct-to-Film) stand out as a revolutionary technique that has captured the attention of businesses and creatives alike. This innovative printing method allows for exceptional flexibility and detail, enabling designers to bring their artistic visions to life on a variety of materials. Whether you’re looking to personalize custom apparel or produce high-quality prints, DTF Transfers offer a compelling alternative to traditional methods like sublimation printing. With the ability to print complex designs with vibrant colors on fabrics such as cotton and polyester, DTF is quickly becoming a popular choice in the competitive landscape of custom apparel printing. Join us as we delve deeper into the seamless advantages of DTF compared to sublimation and other printing techniques.

Exploring the world of Direct-to-Film printing, also known as DTF Transfers, reveals a versatile and efficient method for creating stunning apparel designs. This modern printing technique, in contrast to sublimation processes, focuses on transferring intricate designs from a film directly onto fabric, accommodating a range of materials from cotton to blends. As the apparel industry continues to innovate, the distinction between DTF and sublimation techniques highlights the diverse options available for creators. Each fabric printing method presents its own set of benefits and limitations, making it essential for businesses to understand which approach aligns best with their needs. In this discussion, we’ll compare these popular printing techniques, shedding light on their relative strengths to help you navigate your design journey.

Comparing DTF Transfers and Sublimation Printing Techniques

The comparison between DTF Transfers and sublimation printing is a vital aspect for those involved in custom apparel printing. Both methods serve unique purposes and target different fabrication needs. To illustrate their differences, consideration of their key processes and fabric compatibility is essential. DTF Transfers utilize a film that captures designs, which are then transferred to a variety of fabrics through heat application. This flexibility allows for an expansive range of materials, including cotton and blends, while sublimation is tightly focused on polyester, embedding vivid colors directly into the fabric. For businesses seeking versatility, DTF is often preferred due to its wide applicability.

In addition to fabric compatibility, the capabilities of design detail also distinguish these technologies. DTF Transfers excel in reproducing intricate patterns and color variety thanks to their adhesive film method. Conversely, sublimation’s ability to create all-over prints without seams means longer, designs can be fully realized without interruptions. This makes sublimation a popular choice for mass production, while DTF is favored for custom jobs that demand intricate design work in smaller quantities.

Frequently Asked Questions

What are DTF Transfers and how do they work?

**DTF Transfers** (Direct-to-Film) involve printing designs onto a special film that is then transferred onto fabric using heat and pressure. This method allows for vibrant colors and intricate designs on a wide range of fabrics, including cotton and polyester.

How do DTF Transfers compare to sublimation printing?

When considering **DTF Transfers vs. Sublimation**, key differences include the types of fabrics used and the durability of prints. DTF can print on various materials, while sublimation is limited to polyester. DTF offers versatility, while sublimation provides more durable, embedded designs.

What types of materials can be used with DTF Transfers?

**DTF Transfers** effectively work on a wide variety of fabrics, including cotton, polyester, and blends. This flexibility makes DTF a preferred choice for custom apparel printing.

What are the advantages of using DTF Transfers for custom apparel?

The advantages of **DTF Transfers** include versatility in fabric choice, fast turnaround times, vivid color reproduction, and flexibility in design complexity, making them ideal for smaller orders and intricate designs.

Are DTF Transfers durable compared to sublimation prints?

While **DTF Transfers** provide vivid prints and versatility, sublimation prints are known for their durability and resistance to fading. DTF transfers may vary in durability depending on the application technique, whereas sublimation embeds dye into the fabric, ensuring longer-lasting prints.

Can you achieve all-over prints using DTF Transfers like in sublimation printing?

**DTF Transfers** can achieve impressive designs, but they may not match the seamless all-over print capability of sublimation. For intricate and continuous designs without interruptions, sublimation is typically the better option, especially on polyester fabrics.

| Feature | DTF Transfers | Sublimation |

|---|---|---|

| Process | Print on a special film, then transfer with heat and pressure. | Uses heat to convert dye into gas, bonding with polyester fabrics. |

| Materials | Works on cotton, polyester, and blends. | Effective on polyester fabrics and treated substrates. |

| Advantages | Versatile, vivid colors, fast turnaround, design flexibility. | Highly durable, allows all-over prints, vibrant color fidelity. |

| Challenges | Long drying time, variable durability. | Limited to polyester; requires careful color adjustments. |

Summary

DTF Transfers are a revolutionary technology in the printing industry that provides flexibility and high-quality results. As you navigate the various printing methods available for custom apparel, understanding the strengths of DTF Transfers versus sublimation printing will enable you to make informed choices. While DTF offers versatility and fast production for a variety of fabrics, sublimation stands out for its durability and vibrant results on polyester. Your specific project requirements and material compatibility will ultimately guide your decision in selecting the right printing method.