DTF transfers, or Direct-to-Film transfers, are changing the landscape of custom apparel printing by delivering high-quality, vibrant designs on a wide range of fabrics. This innovative method enables users to create intricate prints that are not only durable but also remarkably detailed. If you’ve been curious about how to use DTF transfers effectively, our comprehensive tutorial will guide you through each step of the process. From understanding the essential DTF printing equipment you’ll need to mastering the printing techniques, this guide serves as a perfect introduction. Join us as we explore the exciting world of DTF transfers and unlock new creative possibilities for your designs!

Also known as direct film printing, DTF transfers represent a significant advancement in the realm of garment decoration and customization techniques. By utilizing specialized film that showcases striking images, this method allows for an array of designs to be seamlessly transferred onto various fabric types. If you’re eager to delve into the mechanics of this modern printing solution, our detailed DTF transfer tutorial is designed to equip you with the knowledge and skills needed. Learn about the necessary DTF transfer equipment, discover expert tips on crafting beautiful designs, and enhance your understanding of this powerful printing process. Explore how these innovative techniques can elevate your custom apparel business and unleash your creative potential!

Getting Started with DTF Printing Equipment and Supplies

To embark on your DTF printing journey, it’s crucial to gather the right equipment and supplies that will ensure high-quality results. First and foremost, investing in a dedicated DTF printer is essential, as it is tailored to produce vibrant colors on transfer films. Brands like Epson and Roland have specialized models that many professionals recommend for their reliability and print quality. Additionally, a robust heat press machine is critical to successfully transferring designs from the film to various fabric types. Make sure to choose a press that allows for precise temperature and pressure control, as these factors greatly influence the success of your transfers.

In addition to the printer and heat press, don’t forget the other essential materials for DTF printing. You’ll need high-quality DTF transfer films specifically designed to handle the ink and adhere properly to fabrics when heat is applied. Alongside the film, adhesive powder is another key material that binds the printed ink during the heat transfer process. All these components work together seamlessly to create stunning designs that can adorn a variety of custom apparel, making them a crucial investiture for any start-up or seasoned business in the custom apparel printing industry.

Frequently Asked Questions

What are DTF transfers and how do they work?

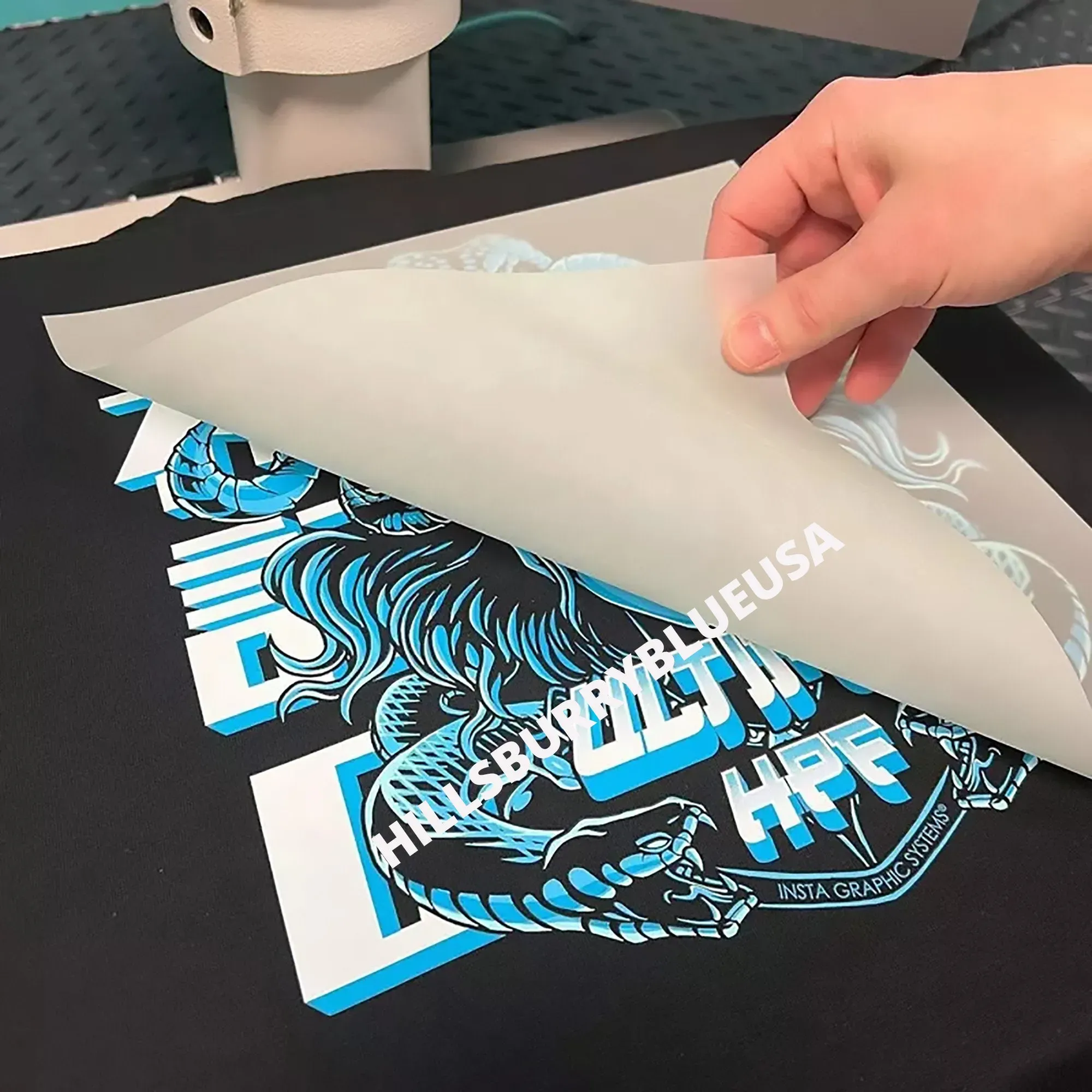

DTF transfers, or Direct-to-Film transfers, involve printing an image onto a special film that is then heat pressed onto fabric. This innovative printing method allows for intricate designs and vibrant colors on various types of fabrics, making it a popular choice in custom apparel printing.

What equipment do I need for DTF printing?

To get started with DTF printing, you will need a DTF printer, a heat press machine, transfer film, adhesive powder, and graphic design software. Each piece of equipment plays a crucial role in producing high-quality DTF transfers.

How do I create designs for DTF transfers?

Creating designs for DTF transfers involves using graphic design software like Adobe Illustrator or CorelDRAW. Make sure your design is in CMYK color mode and adjust the print settings according to your DTF printer specifications for optimal results.

Can anyone use DTF transfers for custom apparel printing?

Yes! DTF transfers are accessible for both beginners and experienced printers. With the right equipment, materials, and a step-by-step understanding of the DTF transfer process, anyone can create stunning custom apparel.

What is the curing process in DTF transfers?

The curing process in DTF transfers involves using a heat press to firmly bond adhesive powder to the printed ink. Typically, the adhesive is cured at approximately 160°C (320°F) for about 30 to 60 seconds, ensuring a strong transfer to the fabric.

How do I care for DTF printed garments?

To maintain the integrity of DTF printed garments, they should be washed inside out in cold water. Avoid harsh detergents and tumble drying, as these can damage the prints and shorten their lifespan.

| Aspect | Details |

|---|---|

| Understanding DTF Transfers | DTF transfers involve printing an image onto a special film which is then heat pressed onto fabric. It allows for detailed designs and vibrant colors on various fabric types. |

| Required Equipment | Key equipment includes a DTF printer, heat press machine, transfer film, adhesive powder, and graphic design software. |

| Design Creation | Designs should be created in graphic software, ensuring they are set to CMYK color mode for accurate printing. |

| Printing Process | Print the design on the transfer film, and apply adhesive powder while the ink is still wet. |

| Curing the Transfer | Cure the adhesive with heat at 160°C for 30-60 seconds to ensure it binds well. |

| Heat Transfer to Fabric | Preheat the fabric, place the transfer film face down, and heat press for 10-15 seconds. |

| Caring for DTF Transfers | To maintain DTF prints, wash items inside out in cold water and avoid harsh detergents. |

| Resources | Video tutorials and online courses can enhance learning about DTF printing, including guides from Printful. |

Summary

DTF Transfers are a groundbreaking technique in the custom apparel industry, enabling individuals and businesses alike to create vibrant and intricate designs on various fabrics. This tutorial has outlined essential knowledge and equipment needed to embark on your DTF printing journey. From understanding the technology and design creation to the printing process and caring for finished products, each step is crucial for achieving high-quality results. As you explore DTF Transfers, you’ll discover their potential not only for personal projects but also for expanding business opportunities in custom printing. Engage with the available resources to refine your skills further, and you’ll be well-equipped to create stunning apparel that stands out.