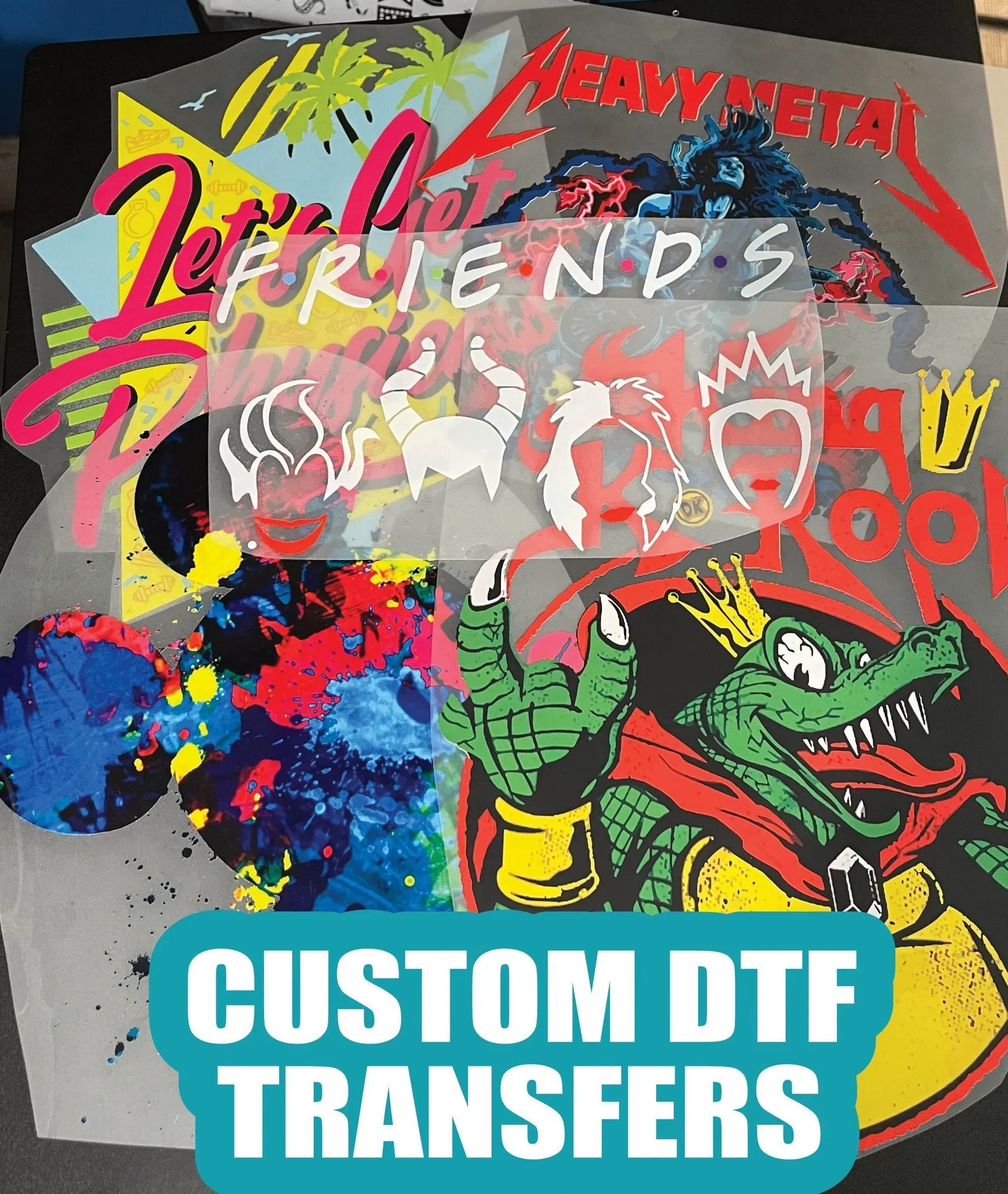

In the world of custom apparel, DTF Transfers have emerged as a game-changing technology that can vastly enhance the quality and efficiency of printing. As small businesses look to differentiate themselves in a saturated market, understanding the Direct-to-Film printing process becomes crucial for producing eye-catching designs that resonate with consumers. Unlike traditional methods, DTF transfers offer a unique combination of versatility and durability, allowing entrepreneurs to cater to diverse fabric types effortlessly. This innovative approach not only streamlines the custom apparel production process but also supports the growing demand for personalized products. In this article, we will explore the ins and outs of DTF transfers, from selecting the right DTF printing equipment to mastering the application process, ensuring your small business stands out in the competitive landscape.

When discussing the innovative techniques used in custom apparel production, terms like direct-to-film printing and DTF transfer process may come to mind. These methods revolutionize how businesses create high-quality graphic designs on various materials, making them particularly appealing for small business printing needs. The process involves applying a specially coated film that adheres to fabrics seamlessly, providing a durable and vibrant finish that modern consumers crave. Furthermore, mastering this technique can open up new avenues in the competitive market for personalized clothing. By adapting to these advanced printing solutions, entrepreneurs can effectively meet consumer demand while also improving their operational efficiency.

Understanding the DTF Transfer Process

The DTF transfer process begins with designing graphics that resonate with your target audience. Utilizing software like Adobe Illustrator or CorelDRAW is essential for creating high-quality designs. Factors such as color choice and format are crucial. Bright inks characteristic of DTF transfers can elevate your design, making it stand out on various fabrics. Additionally, ensuring your designs are saved in compatible formats ensures smooth printing without loss of detail.

Once your designs are prepared, it’s time to understand the technology behind DTF transfers. At the core of DTF printing is a specialized film that captures your designs, which can then be transferred onto fabric with ease. The correct use of DTF printing technology not only allows for vivid imagery but also empowers small businesses to expand their product lines effectively, tapping into the growing demand for custom apparel.

Choosing the Right DTF Printing Equipment

Selecting suitable DTF printing equipment is a critical step for small businesses aiming to get into the custom apparel industry. Affordable yet reliable DTF printers are now widely available, specifically designed for smaller operations. When choosing a printer, pay special attention to features such as resolution, build quality, and compatibility with various materials. Investing in a good printer can significantly affect the quality of the final product.

In addition to the printer, the software you choose to pair with it is equally important. A user-friendly software program that integrates seamlessly with your printer will streamline the workflow, allowing you to focus more on creativity and less on technical challenges. Ensure that your chosen software supports all necessary file formats for DTF printing, facilitating an efficient design-to-production process.

Creating Eye-Catching Custom Apparel

In the world of custom apparel, creating visually appealing designs is key. When leveraging DTF transfers, your designs can feature intricate details and vibrant colors, appealing to customers’ preferences. Make sure to follow current trends and use high-resolution images to capture the attention of potential buyers. Incorporating elements that reflect your brand’s identity while showcasing creativity can draw in a loyal customer base.

Moreover, remember that the fabric you use also plays a significant role in how your design appears. DTF transfers are versatile and can be applied to a wide range of materials including cotton, polyester, and blends. Experimenting with different fabric types can help you determine what works best for your designs and will ultimately enhance the overall quality and durability of the custom apparel.

The Importance of Quality Control in DTF Transfers

Quality control is a paramount step in the DTF transfer process. After the printing and transferring of designs, it’s crucial to assess several elements to ensure high standards are met. Check for vibrancy in colors and adherence of the designs to the fabric, as both will affect your customers’ satisfaction. A well-executed quality control process can help identify any potential issues before products reach the market.

Beyond initial checks, consider the longevity of your prints. More than just vibrant colors, the ability of the DTF transfer to withstand washing and regular wear and tear speaks volumes about your brand’s reliability. Customers expect durability, especially in apparel, and any failure in this area could harm your reputation. Invest time in this critical stage to solidify your brand in the competitive custom apparel market.

Marketing Strategies for Your DTF Products

Implementing effective marketing strategies for your DTF-printed products is essential to stand out in a saturated market. Utilize social media platforms such as Instagram and Facebook to showcase your designs. Post behind-the-scenes content of the DTF transfer process to engage your audience and build a community around your brand. By presenting your products visually and effectively, you can attract more customers who appreciate unique custom apparel.

Moreover, consider leveraging influencer partnerships to promote your DTF products. Influencers can extend your reach by targeting specific demographics that align with your brand. By collaborating with those who have a genuine interest in custom designs, you not only boost your visibility but also build credibility in the market. An effective marketing strategy can significantly enhance your sales and customer loyalty.

Future Trends in Custom Apparel and DTF Printing

As the custom apparel industry evolves, understanding future trends will help your small business stay ahead. The demand for personalization is continually growing, and DTF printing is well-positioned to meet this need. Customers increasingly seek unique items that reflect their personality, and businesses that can offer tailored solutions will thrive. Keeping an eye on trends in consumer preferences will place your business at the forefront of this shift.

In addition, sustainable practices in DTF printing are becoming increasingly popular. More consumers are favoring companies that implement eco-friendly solutions in their production processes. By researching and utilizing sustainable materials and practices, your business can appeal to the environmentally conscious consumer base, setting your offerings apart and enhancing your brand’s reputation.

Frequently Asked Questions

What are DTF transfers and how do they work?

DTF transfers, or Direct-to-Film transfers, are a printing technology that allows for high-quality graphics to be printed on various fabrics. The DTF transfer process involves printing a design onto a special film coated with adhesive, which is then heat applied to the fabric. This method is particularly popular among small businesses due to its versatility, cost-effectiveness, and ease of use.

What equipment do I need for DTF printing in my small business?

To start DTF printing, you will need essential DTF printing equipment, including a DTF printer that offers high resolution, a heat press for transferring designs, and compatible software for graphic design. Investing in quality DTF printers and heat presses is crucial for ensuring durability and vibrant prints on your custom apparel.

What materials can I use with DTF transfers?

DTF transfers are compatible with a wide range of materials, including cotton, polyester, and blended fabrics. This versatility makes DTF printing an ideal choice for small businesses aiming to diversify their custom apparel offerings without needing separate setups for different textiles.

How do DTF transfers compare to other printing methods?

Compared to traditional methods like screen printing and direct-to-garment (DTG) printing, DTF transfers offer advantages such as lower startup costs, high-quality prints, and the ability to transfer on various fabric types. This makes DTF printing a favored choice for small businesses looking to produce custom apparel efficiently.

What are the steps involved in the DTF transfer process?

The DTF transfer process involves several key steps: first, you’ll design your graphics using design software; next, print the design onto special film; apply adhesive powder and heat cure it; transfer the design to fabric using a heat press; and finally, perform quality checks to ensure vibrancy and durability of the print.

Is training necessary for mastering DTF printing?

While extensive training is not required to master DTF printing, familiarizing yourself with the DTF transfer process, equipment, and best practices is beneficial. Many resources, such as online tutorials and workshops, are available to help small business owners quickly learn how to effectively use DTF printing for custom apparel.

| Key Point | Details |

|---|---|

| Introduction | DTF Transfers are a game changer for small businesses in custom apparel. |

| What are DTF Transfers? | A printing technology that transfers high-quality graphics onto fabrics using a special film. |

| Advantages | Cost-Effective, Versatile, Durable, and Easy to Use. |

| Mastery Process Steps | Designing, Choosing Equipment, Printing, Transferring to Fabric, Quality Control. |

| Resources for Learning | Online tutorials, workshops, and forums for support. |

| Market Trends | Growing demand for personalization and eco-friendly practices. |

Summary

DTF Transfers provide a powerful opportunity for small businesses looking to thrive in the custom apparel market. By embracing this innovative printing technology, entrepreneurs can create unique, personalized products that meet the growing consumer demand. The advantages of DTF printing—such as its cost-effectiveness, versatility, and ease of use—position small businesses to succeed in a competitive landscape. Moreover, understanding the mastery process from design to fabric and leveraging available resources allows business owners to optimize their production strategies. As market trends continue to evolve, with a strong push for personalization and sustainability, mastering DTF Transfers could be the key to standing out and achieving lasting success in the custom apparel industry.