In the vibrant landscape of modern fashion, DTF transfers are revolutionizing how designs are brought to life on garments. This innovative printing method, known as Direct-to-Film (DTF) transfers, stands out for its efficiency and quality, making it a favorite among designers and brands alike. With DTF technology, the fashion industry is embracing a more sustainable approach, significantly reducing waste and supporting eco-friendly garment printing practices. As consumer demand shifts towards more environmentally conscious choices, DTF transfers offer a seamless solution that aligns creativity with sustainability. In this exploration, we will delve into how DTF transfers are reshaping the apparel market and driving fashion industry innovations.

Exploring the realm of Direct-to-Film (DTF) printing reveals a transformative technology that’s making waves across garment production. Often referred to as film printing or DTF technology, this method allows designers to easily print artwork onto a special film that adheres beautifully to fabric materials. The approach not only enhances design vibrancy but also supports a push towards more sustainable fashion printing methods, catering to the growing consumer interest in eco-friendly practices. In a landscape where innovation meets environmental responsibility, understanding the intricate details and benefits of DTF transfers is essential for anyone involved in the fashion sector. As we navigate through this discussion, we’ll highlight the key advantages and applications of this cutting-edge technology.

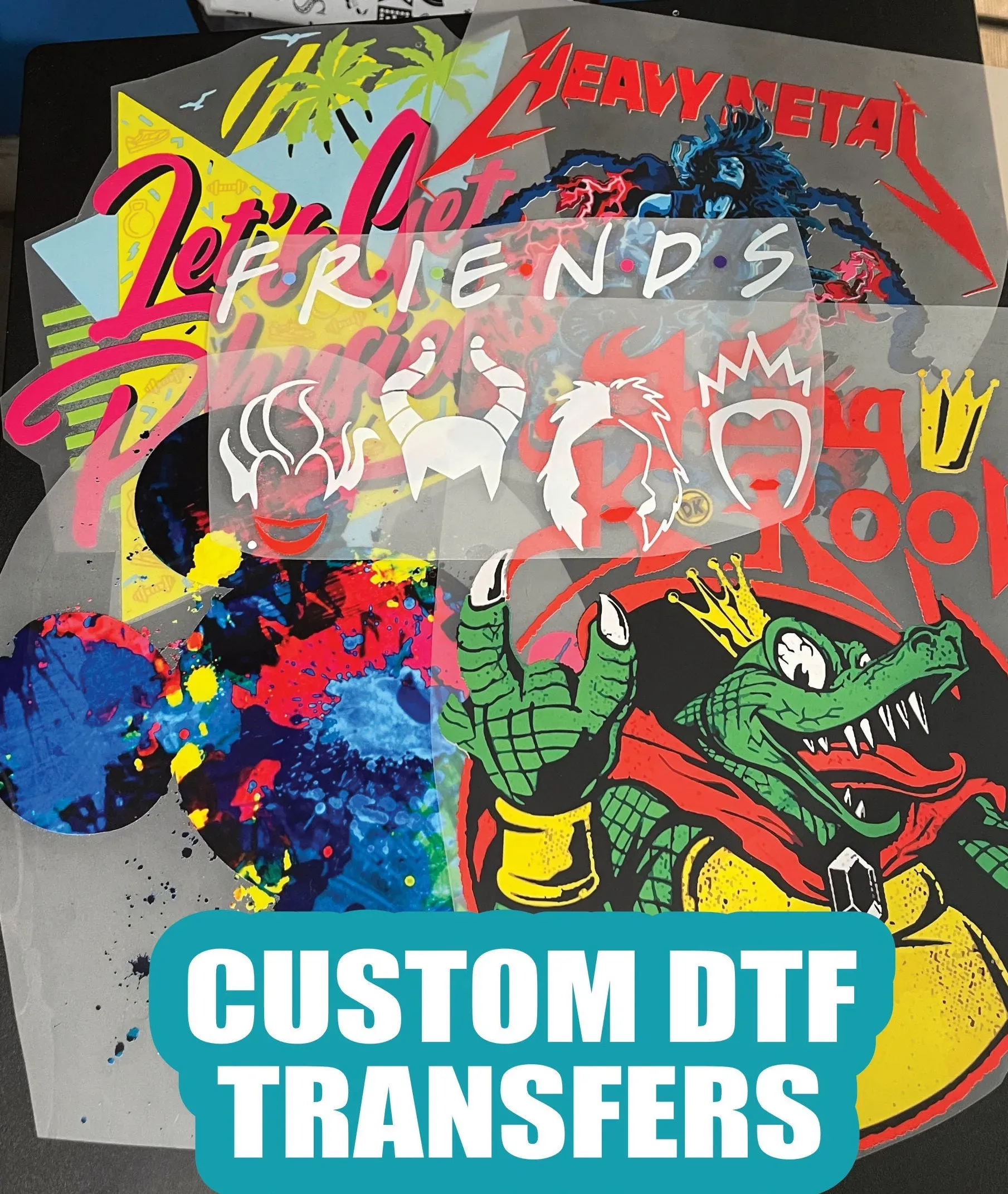

Understanding DTF Transfers: A Deep Dive into DTF Technology

DTF transfers, or Direct-to-Film transfers, represent a revolutionary technique in garment printing that combines innovation with efficiency. By enabling designers to print directly onto a specialized film, DTF technology provides the flexibility to work with a range of fabrics, making it a versatile choice for both amateur and professional garment producers. This method offers the capacity to produce intricate designs with vivid color accuracy, surpassing traditional printing processes which often struggle with detail and vibrancy.

Moreover, the process of DTF printing involves minimal waste compared to conventional approaches, aligning with the industry’s shift towards sustainable practices. By using less ink and facilitating easier color mixing, DTF technology not only conserves resources but also minimizes environmental impact. This alignment with eco-friendly garment printing makes DTF transfers an attractive option for fashion brands aiming for a greener operational model.

Sustainability Meets Style: Eco-Friendly Benefits of DTF Transfers

As the fashion industry grapples with its environmental footprint, DTF transfers offer a beacon of hope for sustainable apparel production. The method is designed to reduce the amount of waste generated during the printing process without compromising the quality of the finished product. Unlike traditional fabric printing methods that often lead to excess material use, DTF technology ensures that every drop of ink counts, making it a favorite among brands committed to eco-friendly practices.

Furthermore, the longevity of DTF prints adds another layer to its sustainability story. DTF technology produces durable images that withstand numerous washes without fading, ensuring that garments maintain their vibrant appeal over time. This durability translates into less waste, helping brands reduce the volume of discarded prints and finished products, thus fostering a more sustainable fashion ecosystem.

Exploring the Commercial Impact of DTF Technology on the Fashion Industry

The commercial potential of DTF technology is vast and rapidly growing, as evidenced by platforms like Snuggle DTF that have emerged to support the print trade. This web-to-print service simplifies the integration of DTF transfers into garment production, enabling brands—from startups to established fashion lines—to incorporate high-quality printing without overwhelming capital investment. Such platforms empower smaller businesses by providing access to advanced printing technologies that were previously only available to large-scale manufacturers.

Additionally, the ability to create low run orders without hefty setup costs opens new avenues for creativity in the fashion industry. Designers are now able to experiment with limited edition pieces and unique styles, appealing to consumers’ desires for originality and exclusivity. This streamlined process ultimately cultivates a more dynamic market where innovation flourishes, and eco-friendly fashion becomes accessible to a broader audience.

Creative Applications: Versatility of DTF Transfers in Fashion Design

DTF transfers are acclaimed for their incredible versatility, allowing for unique applications across a vast array of fashion items. From basic t-shirts to high-end accessories, DTF technology caters to diverse textile materials, making it possible for designers to infuse creativity into their collections without being restricted by medium. The flexibility of DTF enables artists to play with different textures, prints, and color schemes, resulting in standout designs that resonate with contemporary fashion trends.

Furthermore, as the marketplace becomes increasingly saturated, the unique capabilities of DTF printing provide a competitive edge. Brands can swiftly pivot to align with emerging trends and consumer demands. Whether creating bespoke garments for local communities or launching seasonal collections, DTF technology allows designers to experiment and adapt, reinforcing their relevance in an ever-changing industry.

Quality Assurance: The High Standard of DTF Output

The quality output of DTF transfers is one of its most touted advantages in the fashion realm. The revolutionary printing technique creates vibrant, high-resolution images that not only captivate consumers but also uphold the reputation of brands. The brilliant colors and meticulous detail made possible through DTF printing mean that businesses can provide their customers with garments that look strikingly professional, enhancing both brand image and consumer satisfaction.

Additionally, the longevity of DTF prints is a critical factor in maintaining quality standards. These prints are resistant to fading and cracking, even after multiple wash cycles, thereby ensuring that the aesthetic integrity of the garment remains intact. This durability not only pleases end consumers but also reinforces a brand’s commitment to quality, ultimately translating to higher customer retention and loyalty in the competitive fashion market.

Navigating Challenges: Considerations in Adopting DTF Technology

Despite the many benefits that DTF technology presents, brands must also consider the challenges associated with its adoption. For small businesses, the initial costs of purchasing DTF printers and materials can be substantial. It’s essential for brands to conduct thorough research and planning to determine if the investment aligns with their overall business strategy.

Moreover, as DTF technology gains traction, maintaining consistent print quality across various projects can pose a significant challenge. Understanding the intricacies of DTF processes and forming partnerships with reliable suppliers can help mitigate these issues. Continuous training and keeping abreast of the latest technological advancements are vital for brands that want to effectively leverage DTF printing in their operations.

Frequently Asked Questions

What are DTF transfers and how do they work in fashion printing?

DTF transfers, or Direct-to-Film transfers, are a modern printing technology that allows designers to print vibrant designs onto a special film, which can then be heat-pressed onto garments. This method is known for its ability to produce intricate details and delivers high-quality results, making it a popular choice in the fashion industry for sustainable printing.

How do DTF transfers contribute to sustainable fashion practices?

DTF transfers significantly reduce waste in apparel production, aligning with sustainable fashion practices. This technology minimizes ink and fabric waste compared to traditional printing methods, allowing brands to produce colorful prints efficiently while decreasing their environmental impact.

What are the advantages of using DTF technology for garment printing?

The advantages of DTF technology include sustainable printing capabilities that reduce waste, cost-effectiveness for low run orders, high-quality output with vibrant colors, and the versatility to print on various textile materials. These benefits make DTF transfers an attractive option for fashion brands innovating in eco-friendly garment printing.

Can DTF transfers be used for various textile types?

Yes, DTF transfers can be applied to a wide range of textile materials, making them highly versatile in the fashion industry. Designers can print on t-shirts, sweatshirts, and accessories, experimenting with different textures and styles to achieve unique designs.

How has the adoption of DTF technology impacted small fashion businesses?

The adoption of DTF technology has positively impacted small fashion businesses by providing accessible premium quality printing options without significant capital investment. Platforms like Snuggle DTF enable easy integration of the technology, allowing small brands to streamline their operations and offer customized designs.

What challenges should brands consider when implementing DTF printing?

Brands should be aware of challenges such as the initial investment in DTF printers and materials, as well as ensuring consistent print quality across projects. It’s essential for companies to invest time in understanding the technology and establishing strong relationships with quality suppliers to overcome these challenges.

| Key Points | Details |

|---|---|

| What are DTF Transfers? | DTF transfers are a printing technology where colorful images are printed on a film and then heat-pressed onto garments, allowing intricate designs to be created efficiently. |

| Sustainability in Apparel Production | DTF technology reduces waste and minimizes ink and fabric waste compared to traditional methods, making it a leader in eco-friendly practices. |

| Commercial Advancements | Platforms like Snuggle DTF facilitate the commercial integration of DTF, making high-quality printing accessible to smaller businesses and promoting operational efficiency. |

| Versatile Applications | DTF technology can be applied to various textile materials, allowing designers to explore limitless creative opportunities. |

| High-Quality Output | DTF transfers produce vibrant colors and durable prints that maintain their aesthetics and integrity even after multiple washes. |

| Trends in the Fashion Industry | DTF transfers facilitate low run orders and unique designs, allowing brands to offer personalized items and meet trends in streetwear and haute couture. |

| Challenges and Considerations | Initial costs for printers and materials can be high, and ensuring consistent quality in projects is essential but challenging for brands. |

Summary

DTF transfers are revolutionizing the fashion industry with their innovative approach to printing and sustainability. These transfers enhance creative possibilities, reduce waste, and offer high-quality outputs, making them a popular choice among designers. As the demand for eco-friendly fashion rises, DTF technology is setting a new standard for garment production, showcasing how creativity can blend with responsibility in modern apparel.