DTF Transfers are revolutionizing the field of heat transfer printing and presenting exciting possibilities for custom garment printing. This innovative technology, known as Direct-to-Film printing, allows designers and businesses to achieve vibrant, high-quality prints with ease and efficiency. By combining the precision of digital printing with a straightforward application process, DTF transfers make it easier than ever to cater to diverse customer needs. As sustainability becomes a priority for consumers, this method stands out not only for its exceptional results but also for its environmentally responsible practices. Dive into the world of DTF printing to discover how it is reshaping the landscape of customized apparel and sustainable printing solutions.

Direct-to-film transfer techniques, often referred to as DTF printing, are emerging as a favorite in the realm of textile decoration. This method offers a unique approach to heat transfer printing by enabling designers to print intricate designs directly onto a special film before transferring them onto various fabrics. With its user-friendly setup and cost-effective nature, it appeals to both established businesses and startups aiming to break into the custom garment printing market. Moreover, these direct-to-film methods are gaining traction due to their ability to produce durable, high-quality prints while aligning with eco-friendly practices in the printing industry. As the demand for personalized and sustainable printing solutions grows, understanding the advantages of DTF technologies is essential for professionals in this dynamic sector.

Understanding DTF Transfers and Their Mechanism

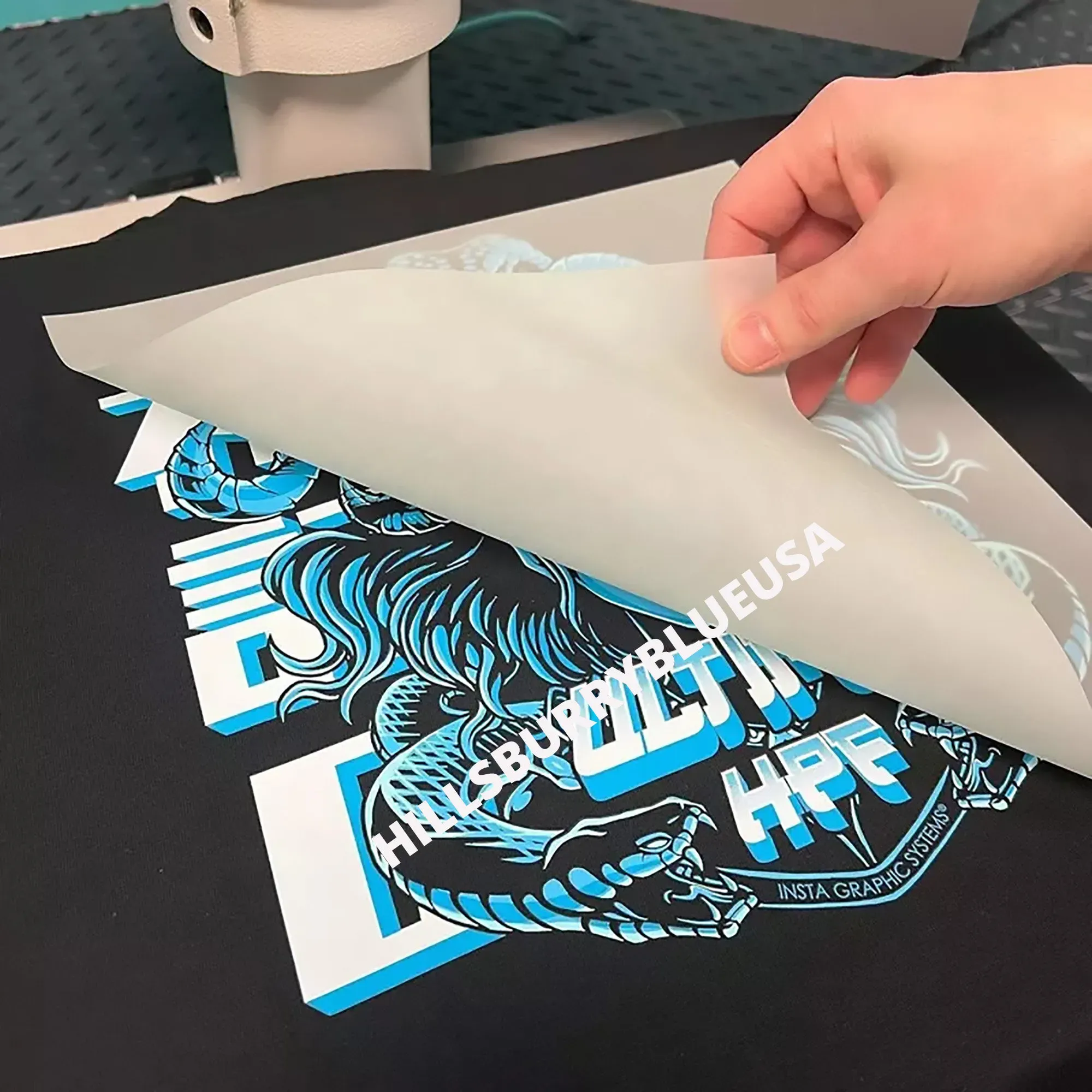

DTF Transfers represent a revolutionary step in the area of heat transfer printing. By leveraging advanced inkjet technology, DTF transfers utilize a unique process where designs are directly printed onto a special film. After printing, a heat-sensitive adhesive powder is applied to the film, which is crucial for binding the design to the fabric. This process ensures that the vibrant colors and intricate details of each print are preserved, providing an unmatched level of quality in custom garment printing.

The actual transfer process involves heat pressing the film onto the fabric, allowing for a perfect bond to form that can withstand multiple washes. What sets DTF apart is its versatility; it works exceptionally well on a variety of fabrics, including cotton, polyester, and blends. Thus, businesses are not only able to produce high-quality prints but also cater to diverse client preferences and market demands.

The Versatility of DTF Printing

One of the standout features of DTF printing is its ability to print on a wide array of fabrics, which vastly expands the potential product lineup for businesses. Unlike traditional heat transfer methods, such as heat transfer vinyl (HTV), which have fabric limitations, DTF technology enables users to create stunning prints on both natural and synthetic fibers. This flexibility opens the door for creative possibilities, allowing for unique and personalized designs ranging from t-shirts and hoodies to athleisure and accessories.

This versatility also mitigates the need for multiple printing setups, thus streamlining operations. For small businesses or custom shops, this means not only reducing equipment costs but also simplifying workflow processes to enhance productivity. With the ability to cater to various fabric choices, businesses can adapt to changing fashion trends and customer demands swiftly.

Cost-Effectiveness and Accessibility of DTF Printing

DTF printing is remarkably user-friendly and accessible, making it an attractive option for many businesses looking to enter the custom garment printing space. It minimizes the complexity of setup often encountered with traditional screen printing processes, enabling newcomers to achieve high-quality results with minimal training. The initial investment in DTF technology is also lower compared to other printing methods, which makes it a viable option for startups and small enterprises.

By adopting DTF transfers, businesses can also leverage the speed of on-demand printing, producing custom designs as orders come in without the extensive downtime typical of some legacy printing methods. This adaptability can lead to substantial cost savings in terms of inventory management and waste reduction, which are common challenges in the printing industry.

Quality and Durability: A Top Priority for Businesses

Quality and durability are paramount in the realm of custom printing, and DTF transfers deliver on both fronts. The integration of high-quality inks and adhesives within the DTF printing process results in vibrant, long-lasting prints that maintain their integrity wash after wash. Customers often prioritize these qualities when selecting custom apparel, and DTF technology ensures that businesses can meet these expectations consistently.

Beyond aesthetics, the durability of DTF prints contributes significantly to customer satisfaction and brand loyalty. Businesses can confidently promise their clients products that will last, which fosters a positive reputation and drives repeat sales. As successful brands know, protecting their reputation hinges on delivering reliable and high-quality products that stand the test of time.

Embracing Sustainability in DTF Printing

In today’s eco-conscious landscape, sustainability is no longer an option but a necessity. DTF printing emerges as a sustainable alternative to traditional printing methods, as it utilizes less energy and generates significantly less waste. The reduction in excess materials and the ability to produce on-demand decrease the overall environmental footprint associated with garment manufacturing.

Additionally, the non-toxic inks used in DTF printing further contribute to its eco-friendliness, allowing businesses to align their production practices with the values of environmentally-aware consumers. As more consumers seek sustainable options, businesses that embrace DTF technology are not only reducing their impact on the planet but are also tapping into a lucrative market demand.

The Future Landscape of DTF Technology in Custom Printing

The future landscape of textile printing is skewed heavily towards the adoption of DTF technology. As e-commerce continues to surge, the demand for personalized and unique apparel remains strong. DTF printing is perfectly positioned to meet this demand due to its efficiency and high-quality output, which allows businesses to respond to market needs effectively.

Market studies indicate that the global DTF printer market is set to expand rapidly, propelled by the growing interest in custom garments and on-demand printing solutions. As both large manufacturers and small custom shops adopt DTF technology, the printing industry will inevitably evolve, reshaping how products are made, marketed, and delivered to customers. By remaining at the forefront of this innovation, businesses can ensure they meet modern consumer expectations and thrive in a competitive market.

Frequently Asked Questions

What is DTF Transfers and how does it work?

DTF Transfers, or Direct-to-Film Transfers, is a printing process where high-quality designs are printed onto a special film using advanced inkjet printers. The printed design is then coated with a heat-sensitive adhesive powder and heat pressed onto fabrics. This method allows for vibrant and durable prints, making it a popular choice in heat transfer printing.

What are the advantages of using DTF printing for custom garment printing?

DTF printing offers numerous advantages for custom garment printing, including versatility in fabric selection, as it works on cotton, polyester, and blends. It’s user-friendly and cost-effective compared to traditional printing methods, requiring less setup and lower equipment costs. Additionally, DTF prints are known for their impressive color vibrancy and long-lasting durability.

Can DTF Transfers be considered a sustainable printing option?

Yes, DTF Transfers are considered a sustainable printing option. This method requires less energy and generates minimal waste compared to traditional printing techniques. As businesses seek eco-friendly practices, DTF printing aligns with the growing consumer demand for sustainable printing solutions.

How does DTF printing compare to traditional screen printing?

DTF printing differs from traditional screen printing in terms of setup and flexibility. While screen printing can be complex and time-consuming, DTF printing streamlines the process, making it user-friendly. DTF also offers greater versatility, allowing for prints on a wide range of fabrics without the limitations found in screen printing.

What types of fabrics can be used with DTF Transfers?

DTF Transfers can be used on a variety of fabrics, including cotton, polyester, and their blends. This versatility enables businesses to produce custom garments for a diverse clientele, expanding their product offerings without needing multiple printing technologies or materials.

Why is DTF technology gaining popularity in the printing industry?

DTF technology is gaining popularity due to its affordability, ease of use, and adaptability. The demand for custom apparel and on-demand printing services is rising, prompting businesses to embrace DTF solutions. This trend is reshaping the textile printing industry as it aligns with modern consumer expectations for unique and personalized products.

| Aspect | Details |

|---|---|

| What are DTF Transfers? | A printing process where designs are printed on a special film, coated with adhesive powder, and then heat pressed onto fabric. |

| Versatility in Fabric Selection | Can print on various fabrics including cotton, polyester, and blends, unlike traditional HTV. |

| User-Friendly and Cost-Effective | Simplifies the printing process, lowering setup times and costs, making it ideal for small businesses. |

| Quality and Durability | Produces vibrant, long-lasting prints that resist fading and cracking after multiple washes. |

| Market Growth and Adoption | DTF printer market is expected to grow due to rising demand for custom apparel and e-commerce solutions. |

| Environmental Considerations | More eco-friendly than traditional methods, requiring less energy and generating less waste. |

| Industry Perspectives | Experts agree on DTF technology’s rising popularity due to affordability and adaptability in the market. |

Summary

DTF Transfers mark a significant advancement in heat transfer printing technology and are quickly becoming the preferred choice among businesses looking to produce high-quality custom designs. This innovative method offers unparalleled versatility across various fabrics, streamlines the printing process for efficiency, and promotes sustainability in operations. As the demand for personalized products continues to grow, DTF Transfers are poised to redefine the printing landscape, enabling companies to meet the changing expectations of today’s consumers while fostering a more environmentally friendly approach in the textile industry.