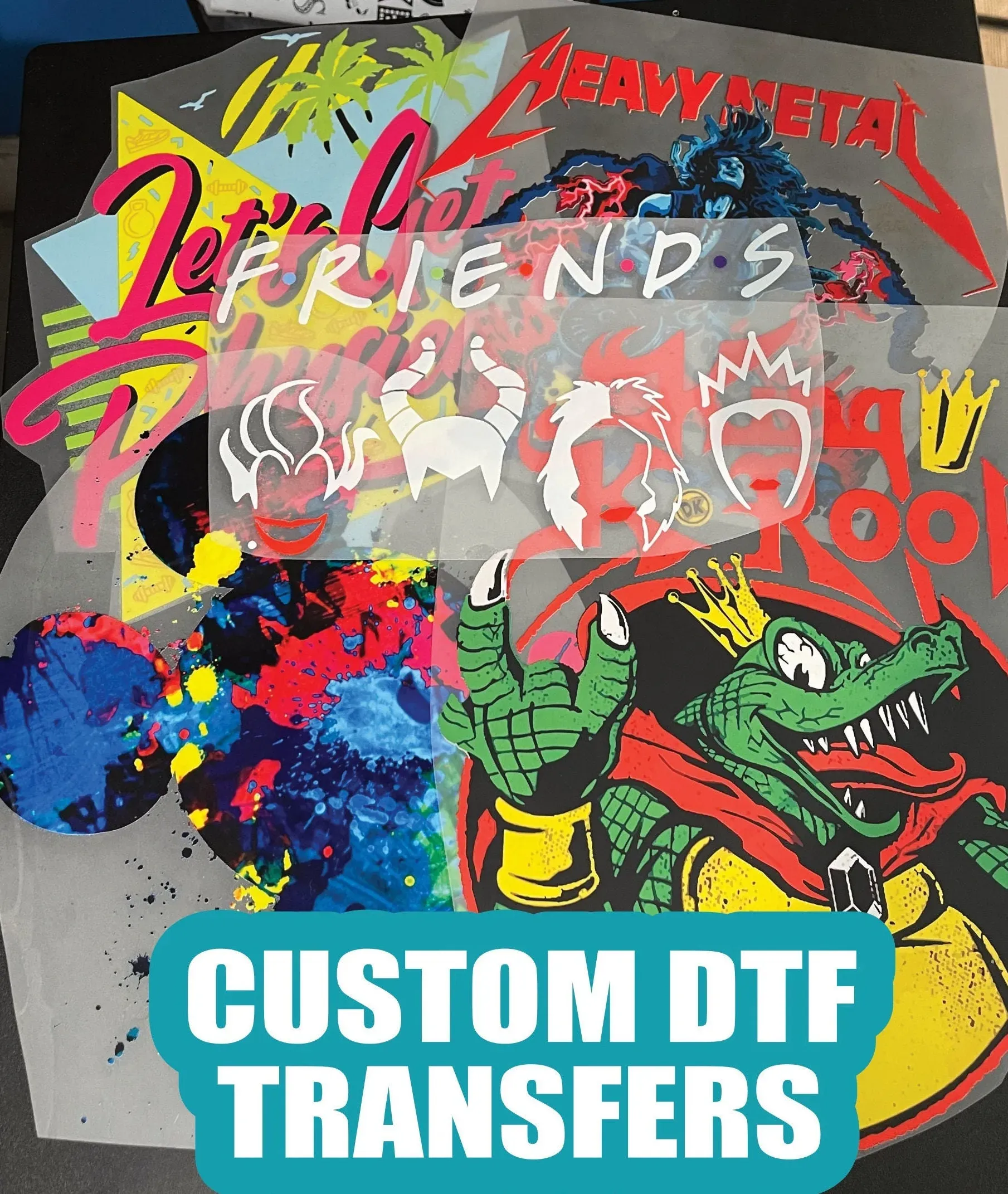

DTF transfers, or Direct-to-Film printing, represent a groundbreaking advancement in the realm of high-quality prints for custom apparel and other textiles. This innovative printing technology allows for precise, vibrant designs to be transferred onto various materials, offering an unparalleled level of detail and color accuracy. Whether you’re a business owner looking to create promotional merchandise or a designer seeking to bring their creative visions to life, DTF transfers provide a versatile and cost-effective solution. As sustainability becomes essential, this method also utilizes eco-friendly inks and practices, making it a conscientious choice in today’s market. Dive into the world of DTF printing and discover how it can transform your print projects into stunning works of art that truly stand out.

Direct-to-Film (DTF) printing, sometimes referred to as film-based transfer technology, is revolutionizing the way high-quality prints are created for various applications. This process enables artists and businesses to achieve intricate designs with vivid colors, making it an ideal method for producing custom apparel and promotional items. Utilizing sustainable printing techniques, DTF allows for less waste and more environmentally friendly operations. As the demand for tailored and unique fabric prints continues to rise, understanding the benefits of this advanced printing method provides an edge in today’s competitive market. By exploring alternatives like this, designers unleash a realm of possibilities for creating personalized textiles that resonate with consumers.

Exploring the Advantages of DTF Transfers in Custom Apparel

Direct-to-Film (DTF) transfers bring a multitude of benefits that are particularly advantageous for custom apparel businesses. This innovative printing method allows for intricate designs and vivid colors, enabling designers to fully realize their creative visions. The versatility of DTF transfers means that they can be applied to various fabric types, including cotton, polyester, and even blended materials, making it easier for brands to offer a wider selection of products that meet customer demands. Furthermore, DTF ensures that the prints are durable and can withstand multiple wash cycles without fading, a critical factor for those producing clothing intended for daily wear.

Additionally, DTF transfers allow for smaller production runs without sacrificing quality or incurring exorbitant costs. This capability is of paramount importance for artists and small businesses looking to test their designs in the market without committing to large print orders. The cost-effective nature of DTF technology empowers creators to explore their designs while maintaining flexibility, allowing young entrepreneurs to thrive in the competitive custom apparel landscape.

The High-Quality Output of DTF Printing Technology

One of the standout features of Direct-to-Film printing is its ability to produce high-quality prints that are rich in color and detail. Unlike traditional printing methods, which may compromise quality for speed, DTF utilizes advanced technology to infuse ink directly onto film, ensuring that the intricate details of a design are captured flawlessly. This high-resolution output is particularly beneficial for brands that prioritize aesthetics, such as fashion labels looking to create eye-catching merchandise that stands out on the shelves.

The commitment to quality in DTF printing also extends to the longevity of the prints. Once transferred, designs maintain their integrity, resisting fading and cracking even after extensive washing or exposure to sunlight. This durability not only enhances the customer experience but also strengthens brand loyalty, as consumers will favor products that deliver lasting value. As a result, DTF printing is gaining traction as a preferred method among companies that demand top-tier quality in their apparel.

Eco-Friendly Benefits of DTF Transfers

Sustainability is a prominent concern in today’s manufacturing landscape, and Direct-to-Film printing addresses these issues head-on with its eco-friendly printing solutions. Most DTF inks are water-based, significantly minimizing the environmental footprint of the textile printing process. This is a stark contrast to other methods that rely on solvent-based inks, which are often harmful to the environment and pose health risks. By choosing DTF, businesses not only contribute to a healthier planet but also attract a consumer base that is increasingly eco-conscious.

Moreover, DTF’s efficiency in material usage means that there is less waste generated throughout the printing process. The technology eliminates excess ink usage and optimizes production runs, aligning with the principles of sustainable manufacturing. This combination of reduced waste and environmentally friendly inks positions DTF printing as an appealing option for businesses striving to align their operations with sustainability goals, as more consumers seek out brands that reflect their values.

Cost-Effective Solutions with DTF Transfers

In an industry where initial costs can be a hurdle, DTF transfers offer a cost-effective solution for both startups and established companies. The ability to produce high-quality prints without the significant setup costs associated with traditional screen printing methods is a game changer. Businesses can create customized apparel or promotional materials for short runs without the financial burden, which is particularly advantageous for those entering the market or looking to experiment with their offerings.

This economic approach does not compromise quality; instead, it allows for a diverse range of products that can be tailored to meet specific customer needs. Startups can leverage DTF technology to create unique merchandise without the risk of overspending, enabling them to allocate resources to other areas of their business. The flexibility and cost-effectiveness of DTF transfers make them an attractive option for graphic designers and entrepreneurs looking to navigate the ever-evolving landscape of custom printing.

Trends and Growth in DTF Printing Market

The adoption of DTF transfers is witnessing significant growth in the printing market, particularly among small to medium-sized enterprises (SMEs) that specialize in apparel and promotional products. Research indicates that as more creators and businesses recognize the benefits of this technology, the demand for DTF printing is expected to soar. The accessibility of DTF printing equipment and the continuous rise of e-commerce have allowed a new wave of brands to emerge, each seeking quality solutions for custom designs.

Indeed, as noted by industry reports, advancements in DTF technology contribute to a projected boom in the market, with businesses looking to enhance their product offerings with high-quality, customizable prints. This trend reflects broader shifts toward personalization and unique customer experiences, suggesting that the DTF market will play a crucial role in shaping the future of custom printing. As innovations continue to unfold, DTF transfers are set to become an essential component of modern printing solutions.

Unlocking Creative Potential with DTF Printing

Incorporating Direct-to-Film printing into design practices unlocks unique opportunities for creativity and expression. Designers are no longer limited by material constraints and can explore vibrant colors and intricate patterns across various substrates. This freedom allows artists to push the boundaries of their creativity, developing one-of-a-kind apparel that captures their aesthetic while appealing to consumers’ desires for originality.

The technological advancements in DTF printing mean that even those with minimal experience in printing can achieve professional results. The straightforward process of transferring designs enables designers to focus less on technicalities and more on their artistic vision. As DTF becomes a staple in the custom printing industry, it offers a platform for creativity to flourish, paving the way for innovative ideas and trends that will shape the future of fashion and merchandise.

Frequently Asked Questions

What is the process behind DTF Transfers and how does Direct-to-Film printing work?

DTF Transfers, or Direct-to-Film printing, involves transferring ink from a specially coated film onto various substrates using heat. This process allows for vibrant colors and intricate designs to adhere firmly to materials like cotton, polyester, and even leather, making it an excellent choice for custom apparel.

Why are DTF Transfers regarded as a superior option for high-quality prints?

DTF Transfers are celebrated for their superior print quality, offering vivid colors and fine details that other printing methods struggle to match. The advanced technology used in DTF printing ensures that designs retain their vibrancy and durability, even after multiple washes and uses.

How does DTF Transfers technology cater to environmental sustainability?

DTF Transfers utilize water-based inks, which significantly reduce the environmental impact associated with traditional printing methods. This sustainable printing approach minimizes waste and aligns with eco-friendly practices, appealing to brands focused on reducing their carbon footprint.

In what ways can DTF Transfers be a cost-effective solution for custom apparel?

DTF Transfers are particularly cost-effective for small production runs since they eliminate the complex setups required by traditional screen printing. This allows businesses and individual designers to produce high-quality prints for limited editions or custom orders without incurring high costs.

What materials can DTF Transfers be used on, and how versatile are they?

One of the key advantages of DTF Transfers is their versatility; they can be applied to a wide range of materials including cotton, polyester, and leather. This makes them ideal for creating custom apparel and promotional items that require quality and adaptability.

What current trends are influencing the growth of the DTF Transfers market?

The DTF Transfers market is experiencing growth due to rising demand for customizable textile products and advancements in printing technology. Small to medium-sized enterprises in the apparel sector are particularly adopting DTF printing, recognizing its versatility and cost-effectiveness as a major benefit.

| Key Points About DTF Transfers | |

|---|---|

| What are DTF Transfers? | A printing method that transfers ink from film to various materials using heat, producing vivid colors and detailed designs. |

| Versatility Across Various Materials | DTF transfers can print on a wide range of materials, making them ideal for custom apparel and promotional items. |

| Superior Print Quality | DTF transfers produce high-quality prints with intricate details and sharp colors, suitable for the fashion industry. |

| Cost-Effectiveness for Short Runs | DTF printing is budget-friendly for smaller orders compared to traditional methods, reducing setup costs. |

| Eco-Friendly Printing Solution | Using mostly water-based inks, DTF printing minimizes waste and aligns with sustainability goals. |

| Emerging Trends in DTF Market | The demand for DTF printing is growing, particularly among small and medium-sized enterprises in the apparel sector. |

Summary

DTF Transfers are revolutionizing the printing industry by providing a versatile, high-quality, and cost-effective solution for various applications. This innovative method not only ensures exceptional print fidelity but also caters to a wide range of materials, from textiles to leather, affirming its adaptability. As sustainability remains a priority, the eco-friendly aspects of DTF transfers make them an appealing choice for businesses looking to reduce their environmental footprint. With the DTF market projected to grow significantly, incorporating DTF transfers represents a strategic opportunity for creatives and businesses alike, driving forward their creative visions and production capabilities.