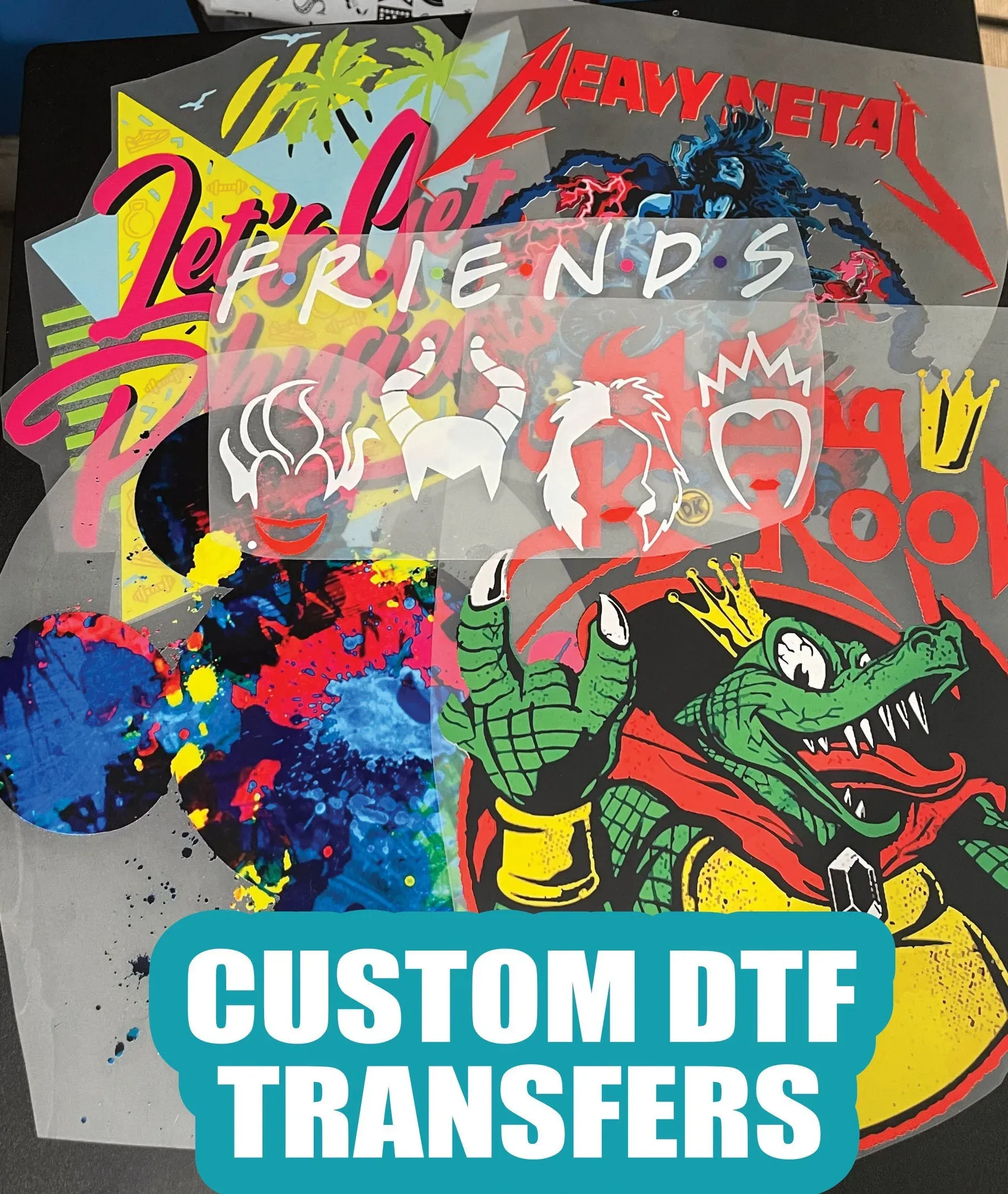

DTF Transfers, or Direct-to-Film transfers, have revolutionized the custom apparel industry by offering vibrant and durable printing solutions. This innovative method allows intricate designs to be printed onto a special film and transferred to fabrics with ease, making it a game-changer for designers and merchandisers alike. The DTF printing process promises exceptional quality on a variety of materials, ensuring that every piece stands out while withstanding the test of time. With its growing popularity, understanding the advantages of DTF transfers is essential for anyone looking to elevate their garment printing game. In this article, we’ll delve into the science behind DTF transfer technology and why it’s the top choice for custom DTF printing.

When considering modern printing techniques for textiles, one cannot overlook Direct-to-Film applications, an advanced method that is gaining traction among clothing manufacturers. This process involves creating stunning graphics that can be seamlessly applied to a vast range of fabrics, providing flexibility and quality that meets both commercial and personal needs. By exploring the ins and outs of this technology, including how it compares to traditional options like screen printing, you can harness the full potential of custom apparel creation. As businesses seek cost-effective and high-quality solutions for custom design work, understanding the intricacies of DTF transfer prints becomes increasingly relevant. Join us as we uncover the benefits and mechanics of this cutting-edge printing solution.

The Technology Behind DTF Transfers

Direct-to-Film (DTF) transfer technology represents a leap forward in the world of custom garment printing. This innovative method utilizes a unique printing process that involves applying DTF inks onto a special film, which is then transferred onto fabric using heat. This not only enhances the quality of the prints but also results in vibrant colors that resist fading over time. Advanced techniques in DTF printing ensure that designs are replicated with remarkable accuracy, making it a preferred choice for customized apparel.

The DTF printing process stands out for its adaptability and precision. Unlike traditional methods that may struggle with detailed designs or fabric types, DTF transfers can cater to a wide array of materials—from cotton and polyester to blends—ensuring the results are as dynamic as the designs themselves. As technology progresses, DTF continues to evolve, integrating new inks and processes that improve quality while remaining environmentally friendly.

Benefits of DTF Printing Technology

One of the most significant advantages of DTF transfer technology is its capacity for producing high-quality prints that maintain their vibrancy and durability even after extensive use. The use of rubberized inks not only adds a level of detail and color saturation that patrons in the custom apparel industry value, but it also ensures that the prints withstand washing and wear. This economic longevity of DTF transfers provides excellent value for businesses and designers alike.

Additionally, DTF printing provides substantial operational flexibility. With minimal setup costs and low minimum order requirements, it’s well-suited for small businesses or individual creators who may not have the capacity for large print runs. This aspect of DTF technology allows for greater freedom in design experimentation, encouraging creativity without the burden of substantial upfront investment.

The DTF Printing Process Unveiled

Understanding the DTF printing process is essential for anyone looking to delve into custom apparel production. The journey begins with the creation of a digital design using graphic design software. This digital blueprint is then printed onto a special PET film using DTF inks that ensure vibrant, detailed reproductions of the original artwork. This initial phase is critical as it sets the groundwork for a successful transfer.

After printing, the process incorporates a unique adhesive application that locks the inks in place while allowing for a seamless transfer to fabric. The final stage utilizes heat to bond the ink and adhesive to the material, resulting in a design that is both striking and robust. This careful sequence of steps is paramount, ensuring that the final product not only looks good but also performs well under the rigors of daily use.

Exploring the Advantages of DTF Transfers

When considering custom apparel production, it’s important to weigh the advantages of DTF transfers. One standout feature is the exceptional level of detail and vibrancy that DTF printing can achieve. This method allows intricate designs to shine on both light and dark fabrics, adding versatility to product offerings. Similarly, the print’s durability is compelling—DTF transfers are known for holding their quality through many cycles of washing without loss of color or clarity.

Moreover, the versatility of DTF transfers extends to a diverse range of fabric types, making it possible to create custom designs on various materials from shirts to accessories. This flexibility enables businesses to cater to varied customer preferences and expand their product lines without the limitations imposed by other printing techniques.

The Eco-Friendly Aspect of DTF Transfers

As sustainability becomes increasingly important in manufacturing and printing, DTF transfers stand out for their eco-friendly attributes. Many modern DTF inks are formulated to minimize environmental impact, allowing companies to offer sustainable custom apparel solutions. Utilizing water-based inks and reducing waste during production aligns with the growing consumer demand for responsible manufacturing practices.

This shift toward environmentally conscious printing solutions complements the high-quality results associated with DTF transfers. Brands that adopt eco-friendly DTF technologies not only contribute to ecological preservation but also resonate with consumers who prioritize sustainability in their purchasing decisions. This duality of quality and responsibility positions DTF printing as an industry leader in the custom apparel market.

Why Choose DTF Transfers for Custom Apparel

Choosing DTF transfers for custom apparel offers numerous benefits that can directly impact the success of your business or brand. The ability to achieve high-quality, detailed prints allows for creativity without compromise. As designs become more complex, DTF technology ensures that the final product matches the artistic vision effectively and efficiently.

In addition to aesthetic advantages, DTF printing is highly efficient, allowing for quick turnaround times on orders, which is crucial in a fast-paced market. The combination of speed, detail, and durability makes DTF transfers a smart choice for anyone involved in the custom apparel industry, paving the way for innovation and growth in individual and bulk operations.

Frequently Asked Questions

What is the DTF printing process and how does it work?

The DTF printing process, or Direct-to-Film printing, involves several steps. First, a design is created digitally and then printed directly onto special PET film using DTF inks. An adhesive powder is applied after printing, followed by heat transfer to bond the design to the fabric. This method allows for high-quality, vibrant prints on various materials.

What are the advantages of using DTF transfers for custom apparel?

DTF transfers offer several advantages, including high-quality results with vibrant colors, versatility across a range of fabrics, and the ability to fulfill low minimum orders. The process is less labor-intensive compared to traditional printing methods, providing quicker turnaround times. Additionally, eco-friendly DTF inks are available, making it a sustainable choice.

Can DTF transfers be used on all types of fabrics?

Yes, DTF transfers are highly versatile and can be used on a wide variety of fabrics such as cotton, polyester, and fabric blends. This makes DTF printing suitable for creating custom apparel, including t-shirts, hoodies, and bags.

How durable are prints created with DTF transfer technology?

Prints created with DTF transfer technology are known for their durability. The use of rubberized inks ensures that the prints can withstand washing and everyday wear without losing quality or vibrancy, making them long-lasting.

Is there a minimum order requirement for custom DTF printing?

Many providers of custom DTF printing offer low or no minimum order quantities, allowing small businesses and independent creators to produce custom designs without significant upfront costs. This flexibility is ideal for small runs or one-off merchandise.

What makes DTF transfers an eco-friendly printing option?

DTF transfers can be considered eco-friendly as many DTF inks and processes are now designed with environmental sustainability in mind. This makes DTF printing a responsible choice for businesses looking to minimize their environmental footprint while still producing high-quality products.

| Key Point | Description |

|---|---|

| What is DTF Transfers? | DTF (Direct-to-Film) is a printing method that transfers designs from film to fabrics using heat. |

| DTF Process Steps | 1. Design Creation 2. Printing on Film 3. Applying the Underbase 4. Adhesive Application 5. Heat Transfer |

| Advantages of DTF Transfers | 1. High-Quality Results 2. Material Versatility 3. No Minimum Orders 4. Simple Process 5. Eco-Friendly Options |

Summary

DTF Transfers are revolutionizing the custom apparel world with their outstanding capability to produce vibrant, high-quality prints on various materials. This innovative printing technique allows for intricate designs to be seamlessly transferred from film to fabric, ensuring durability and longevity in prints. As illustrated in this exploration, the DTF process encompasses design creation, printing, adhesive application, and heat transfer, culminating in a product that meets the diverse needs of consumers and businesses alike. With distinct advantages like versatility on different fabric types, no minimum order requirements, and eco-friendly options, DTF Transfers are an ideal choice for creators looking to elevate their custom apparel game. Embracing DTF technology not only enhances the creative possibilities but also aligns with a future-focused approach in the printing industry.