DTF Transfers, or Direct-to-Film transfers, are redefining the custom apparel landscape with their revolutionary printing capabilities. This cutting-edge technology enables T-shirt businesses to create stunning, durable prints that meet evolving consumer demands. DTF printing innovations showcase vibrant designs that stand the test of time, outperforming traditional methods like screen printing and DTG. With a focus on sustainable printing methods, DTF transfers not only prioritize quality but also reduce environmental impact, appealing to eco-conscious consumers. As we delve deeper into DTF transfer advantages, you’ll discover how these advancements can elevate your T-shirt business and transform the way you connect with your audience.

In the realm of custom garment production, the term “Direct-to-Film” has emerged as a key player, driving innovative printing solutions for apparel enthusiasts. This technology, often referred to as film printing or DTF printing, offers a unique approach to T-shirt production, enabling creators to produce high-quality, customizable designs with remarkable ease. As businesses strive to stay ahead in the competitive custom apparel market, leveraging terms like customized film transfer and innovative printing methods becomes crucial in attracting new customers. With advancements in custom apparel technology paving the way for an eco-friendlier approach, these contemporary printing solutions not only elevate visual appeal but also resonate with sustainability trends. Ultimately, understanding the underlying benefits of utilizing DTF alternatives can significantly enhance the operational efficiency and creative potential of any T-shirt enterprise.

Understanding DTF Transfers and Their Benefits

Direct-to-Film (DTF) transfers are swiftly becoming a staple in the custom apparel industry, primarily due to their remarkable benefits. Unlike traditional methods like Direct-to-Garment printing or screen printing, DTF employs a unique process that allows for greater color vibrancy and longevity. This means that T-shirt businesses can offer products that not only look fantastic upon purchase but also stay bright and intact wash after wash. By leveraging DTF technology, small and large businesses alike can elevate their offerings, ensuring customer satisfaction and repeat business.

Another significant advantage of DTF transfers is their fabric versatility. DTF printing can be used on a wide range of materials, from cotton and polyester to synthetic blends. This adaptability opens up a wealth of creative opportunities for T-shirt designers. Businesses can expand their inventory to include various fabric options without worrying about the limitations often associated with traditional printing methods. As a result, the market can cater to diverse consumer tastes and preferences, fostering an environment of innovation and creativity.

Key Trends Fueling DTF Printing Adoption

The growing demand for customization in the apparel market is a primary trend driving the adoption of DTF transfers. Consumers are increasingly seeking unique products that reflect their individual style and interests. DTF printing technology allows for rapid production of custom designs, making it an attractive option for businesses aiming to meet this demand. Not only does it enable quicker turnaround times, but it also supports a wide range of printing options, from individual designs to bulk orders for events.

Additionally, the global shift towards sustainable practices is propelling DTF printing into the limelight. With many traditional printing methods facing scrutiny due to environmental concerns, DTF printing emerges as a more eco-friendly alternative. Recent developments in inks and materials associated with DTF technologies are increasingly aligning with sustainable printing methods. Consequently, businesses can appeal to environmentally conscious consumers, enhancing their brand reputation and marketability.

The growth of the custom apparel market is another trend favoring DTF transfers. With the rise of on-demand production and a focus on personalized merchandise, DTF technology stands out as an ideal solution for T-shirt businesses. Consumers are drawn to brands that offer tailor-made products, and DTF allows for this style of printing without compromising quality or speed. The ability to cater to this demand can help businesses gain a competitive edge in the evolving fashion landscape.

As demographics shift and new fashion trends emerge, businesses that adopt DTF technology are well-positioned to capture a growing segment of the market. Millennials and Gen Z consumers, in particular, are driving change in purchasing behavior, actively seeking unique and customized apparel that fits their lifestyles. By integrating DTF printing capabilities, businesses can not only stay relevant but also lead in this transformative market space.

Integrating DTF Technology in Your Business

Integrating DTF transfers into your T-shirt business is a straightforward process that can significantly enhance your product offerings. The first step is investing in a quality DTF printer that suits your specific production needs. Advanced printers often come equipped with user-friendly features that streamline the printing process while ensuring high-quality results. Research and compare available options, considering factors such as output speed, print resolution, and ongoing maintenance costs.

Once your equipment is in place, it’s vital to educate yourself and your team about the intricacies of DTF printing technology. Numerous online resources and community forums offer valuable tutorials, tips, and best practices that can facilitate a smoother transition into DTF printing. Familiarizing yourself with the process allows you to operate efficiently, avoiding common pitfalls that can arise during early stages of implementation.

Maximizing the Benefits of DTF Transfers

To fully exploit the benefits of DTF transfers, it’s essential to develop a robust portfolio that showcases your printing capabilities. Create an array of sample designs that highlight the vibrancy and quality of DTF prints. This not only serves as a marketing tool but also allows potential customers to visualize the potential of your products. Use social media platforms and your website to display your portfolio and engage with your audience, driving interest towards your custom apparel.

Marketing the unique benefits of DTF printing can also set your business apart in a competitive landscape. Emphasize aspects such as the durability of prints, the versatility of fabrics, and the eco-friendliness of your offerings in your promotional materials. Utilizing SEO strategies in your content marketing can help attract online traffic, ensuring that potential customers are aware of the advantages of choosing your DTF-printed apparel.

Cost Efficiency of DTF Transfers

One of the standout features of DTF transfers is their cost-effectiveness compared to traditional printing methods. With lower startup costs than screen printing, DTF allows businesses to enter the custom apparel market with less financial risk. Furthermore, the ability to produce high-quality prints in smaller batches means that companies can test new designs without committing to large runs, creating a more flexible pricing model. This financial flexibility is crucial for small businesses and startups operating on tight budgets.

Additionally, the reduced waste associated with DTF printing makes it a more economically favorable option. Businesses can produce exactly what is needed, minimizing leftover inventory and overproduction. As sustainability becomes increasingly prioritized in the consumer market, maintaining efficient printing practices not only helps the business’s bottom line but also aligns with the growing consumer preference for environmentally conscious purchasing decisions.

Future Outlook of DTF Printing Technology

The future of DTF printing technology appears bright, with many innovations on the horizon. As manufacturers continue to refine DTF equipment, we can expect improvements in both speed and print quality. This ongoing development will make DTF an increasingly viable option for high-volume production, attracting more businesses looking to capitalize on the demand for custom apparel.

Moreover, advancements in eco-friendly inks and substrates will likely enhance the sustainability of DTF transfers even further. As consumers become more environmentally aware, businesses that adopt green practices will not only differentiate themselves but also build a loyal customer base. In the years to come, embracing DTF technology could lead businesses to unprecedented growth as they meet both quality and sustainability standards.

Frequently Asked Questions

What are DTF Transfers and how do they work in custom apparel?

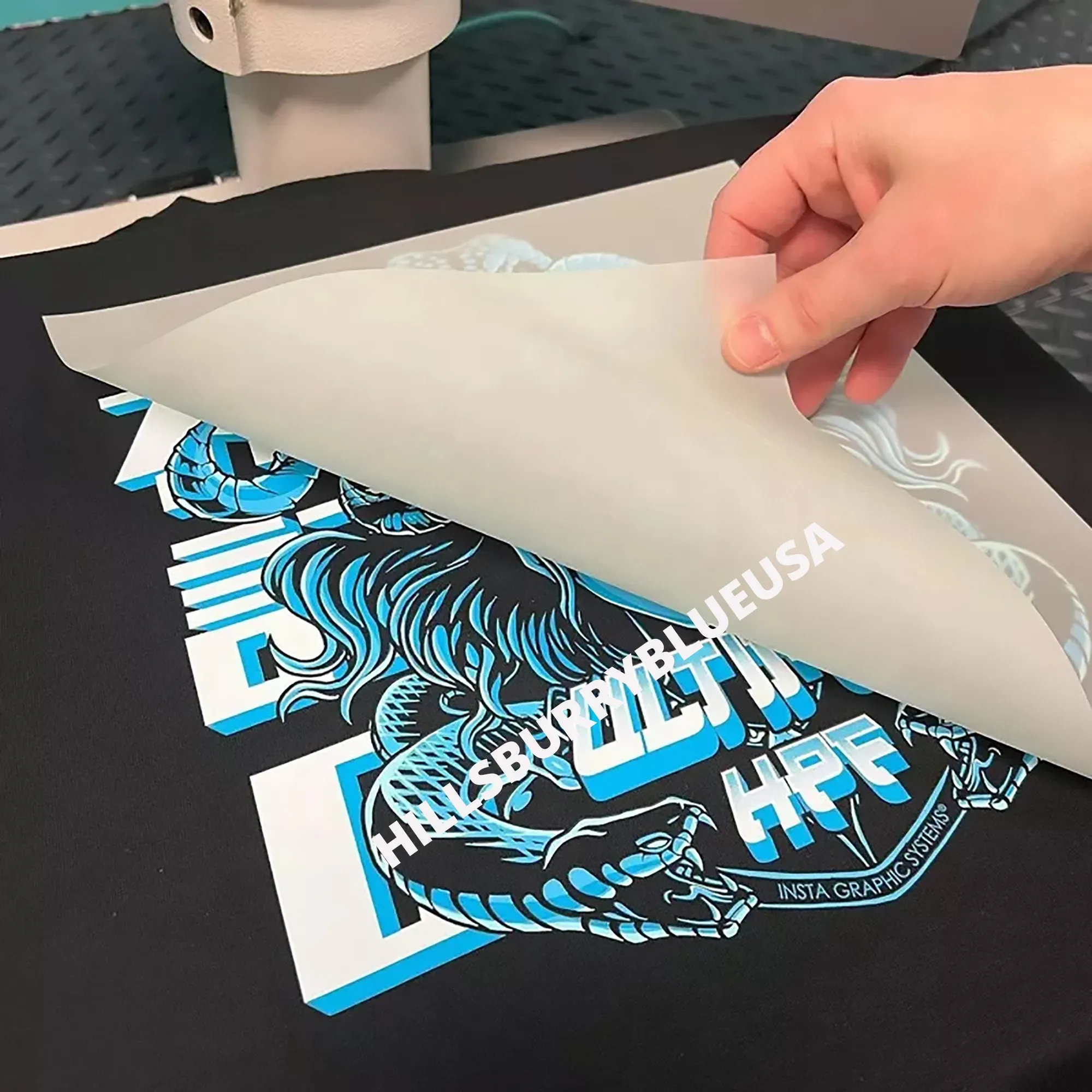

DTF Transfers, or Direct-to-Film printing, is a revolutionary technique in custom apparel that allows for the printing of vibrant, durable designs onto a film which is then heat transferred onto fabric. This method enhances T-shirt printing innovations by ensuring high-quality results across various fabric types.

What are the main advantages of using DTF Transfers over traditional printing methods?

DTF Transfers offer numerous advantages such as superior durability, versatility with different fabrics, cost-effectiveness for small production runs, and faster printing speeds compared to traditional methods like DTG and screen printing. These benefits make DTF technology a smart choice for businesses invested in custom apparel.

How does DTF Transfer technology support sustainable printing methods?

DTF Transfer technology is increasingly aligned with sustainable printing methods due to the development of eco-friendly inks and processes. This allows businesses to minimize their environmental impact while producing high-quality custom apparel that meets consumer demand for sustainability.

Can DTF Transfers be used on any type of fabric?

Yes, one of the notable advantages of DTF Transfers is their versatility; they can print on a wide range of fabrics including cotton, polyester, and blends. This makes them ideal for custom apparel, accommodating various styles and consumer preferences.

What should I consider when investing in DTF Transfer equipment for my T-shirt business?

When investing in DTF Transfer equipment, prioritize high-quality printers that incorporate the latest technology for efficiency and output. Additionally, consider the cost of maintenance, the versatility of the printer, and user-friendly features to maximize your custom apparel production.

How can I effectively market my DTF Transfers to attract customers?

To effectively market your DTF Transfers, highlight their unique advantages such as durability, customization options, and eco-friendliness. Leverage social media and SEO strategies to showcase your designs, connect with your audience, and position your custom apparel brand as innovative and responsive to market trends.

| Key Point | Description |

|---|---|

| DTF Transfers | Innovative printing method for vibrant and durable custom designs. |

| Durability | Holds vibrant colors after multiple washes, ideal for high-use apparel. |

| Fabric Compatibility | Compatible with cotton, polyester, and blends for creative possibilities. |

| Cost-Effectiveness | Lower setup costs and allows small-batch printing without quality loss. |

| Speed and Efficiency | Advanced machines streamline the printing process with automation. |

| Environmental Considerations | Emerging eco-friendly inks reduce environmental impact. |

| Customization Demand | Meets consumer demand for personalization with quick turnarounds. |

| Market Growth | The global DTF printing market is set to expand significantly in the future. |

| Quality Equipment | Invest in advanced DTF printers for maximum efficiency and quality. |

| Team Education | Utilize online resources for smooth operation and setup. |

| Strong Portfolio | Showcase diverse samples to attract customers and connect online. |

| Marketing Strategies | Highlight DTF benefits and employ SEO for better visibility. |

| Trend Monitoring | Adapt to market trends and customer feedback for innovation. |

Summary

DTF transfers have emerged as a revolutionary method for T-shirt businesses looking to enhance their product offerings. This versatile printing technique combines durability, cost-effectiveness, and compatibility with various fabrics, making it a preferred choice for custom apparel. With the growing demand for personalized and sustainable products, DTF transfers align perfectly with current market trends. By incorporating DTF technology, T-shirt businesses can significantly increase their competitive edge, cater to consumer preferences, and fully unlock new opportunities in the dynamic apparel industry.