DTF vs DTG is a common dilemma for brands and print shops exploring the best route for apparel decoration. Understanding DTF printing highlights a film-based transfer that works across many fabrics and places the design on a film before it ever touches the garment. DTG printing excels on cotton, delivering a soft hand and rich detail, though it often requires pretreatment and color management. Direct-to-film vs direct-to-garment comparisons help you map fabric compatibility, color vibrancy, and production workflows to your t-shirt printing methods. A practical cost comparison DTF vs DTG can reveal where smaller runs shine, where versatility matters, and how to balance durability with hand feel.

To frame this topic through an alternative lens, some discussions refer to film-transfer workflows versus direct-on-fabric approaches. In Latent Semantic Indexing terms, the transfer-on-film process can be described as a substrate-first method that uses a powder-adhesive transfer. Conversely, direct-to-garment is often described as ink-on-fiber technology, where the image is applied directly to the fabric. Using these related terms helps readers connect the core ideas across search queries while preserving the practical comparison for designers and operators.

DTF printing vs DTG printing: Core Techniques for T-Shirt Decoration

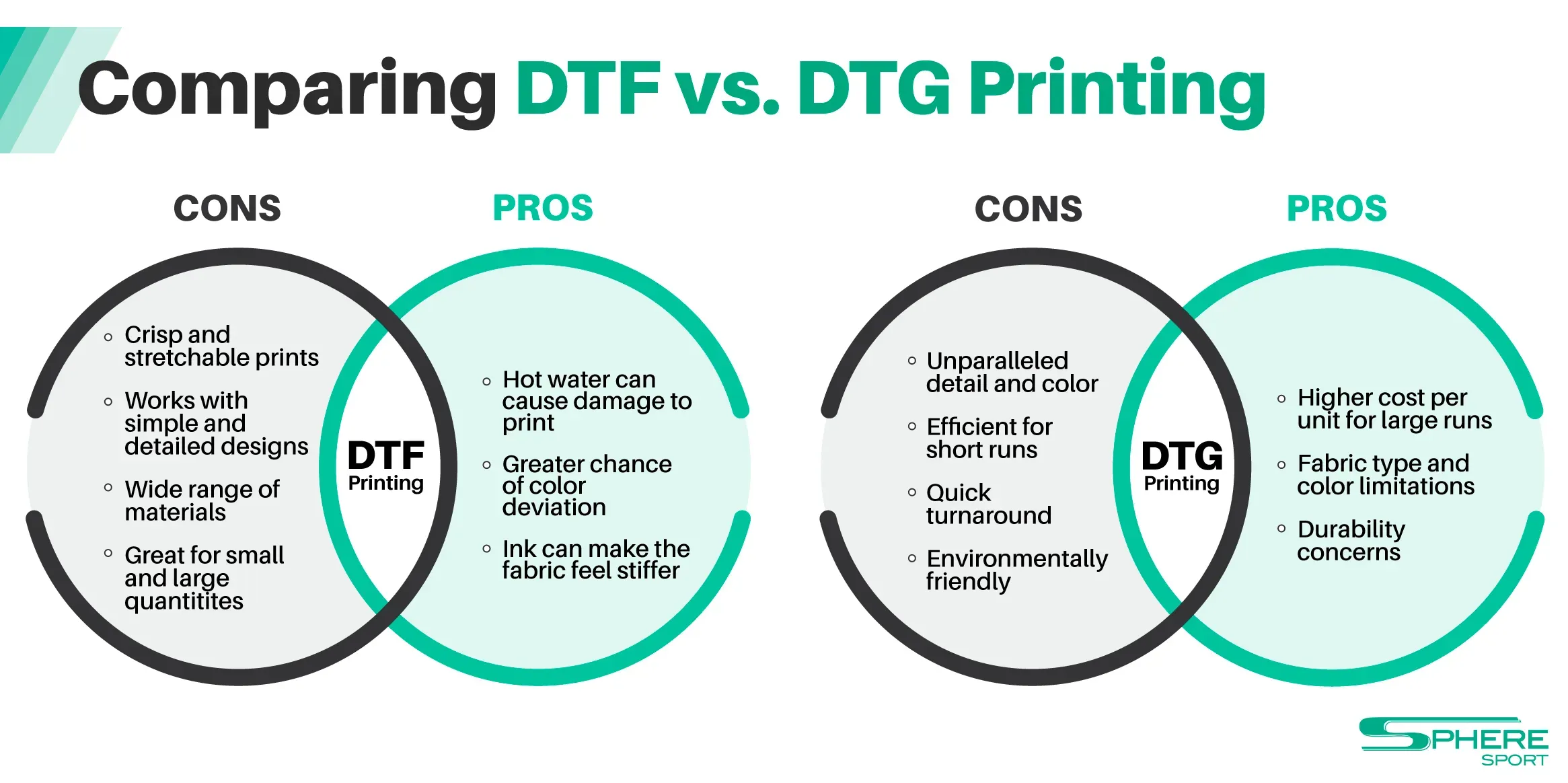

DTF printing and DTG printing are the two dominant approaches for decorating textiles in today’s market. DTF printing, short for direct-to-film, uses a PET transfer film that is coated with adhesive, allowing ink to be bonded and later fused to the garment with heat. This results in a transfer that sits on the fabric’s surface and becomes part of the garment through curing. In contrast, DTG printing applies water-based inks directly onto the fabric, creating a graphic that integrates with the material itself. For those exploring t-shirt printing methods, understanding these fundamental differences helps shape decisions about workflow, texture, and durability.

This descriptive overview highlights how each method translates design into a finished piece: DTF emphasizes a transfer-based approach that can deliver vibrant color and strong wash resistance across a range of fabrics, while DTG offers a direct-on-garment application with a soft hand on suitable fabrics. By recognizing the distinct pathways of direct-to-film versus direct-to-garment processes, brands can tailor their product lines to specific materials, color needs, and finishing requirements.

DTF vs DTG: Direct-to-Film vs Direct-to-Garment Workflows

Direct-to-film vs direct-to-garment workflows define how ink moves from concept to finished apparel. In a DTF workflow, ink is laid down on a film, sealed with a bonding powder, and then transferred to fabric with heat and pressure. This sequence separates the design from the garment until the transfer step, simplifying color management across fabrics and reducing pretreatment concerns on the base material. DTG, by contrast, prints directly onto the fabric, making the garment part of the artwork itself and relying on pretreatment and precise fabric handling to achieve the desired color density.

For teams evaluating t-shirt printing methods, this distinction matters for setup time, color control, and the ability to scale production. Direct-to-film workflows tend to streamline mixed-fabric runs and shorten changeovers, while DTG workflows can excel when the catalog centers on cotton-rich garments with meticulous detailing. Understanding the nuances of direct-to-film versus direct-to-garment helps operators optimize toolpaths, ink use, and overall throughput.

Fabric Compatibility Across Cotton, Polyester, and Blends

Fabric compatibility is a central consideration when choosing between DTF printing and DTG printing. DTF tends to perform reliably across a broad spectrum of fabrics, including cotton, polyester, blends, and some specialty textiles, delivering consistent color and adhesion. This versatility makes DTF a strong option for mixed-fabric runs and markets that require durable results on non-traditional materials. For brands experimenting with new textiles, DTF printing can reduce the risk of fabric-specific failures.

DTG, meanwhile, shines on 100% cotton or premium cotton blends, where the ink lays down with a soft hand and high color fidelity. However, DTG often requires pretreatment and careful color management on synthetics or blends to maintain color density, which can add steps and costs. When evaluating t-shirt printing methods for diverse fabric sets, the choice often hinges on whether the emphasis is on broad fabric compatibility (DTF) or on optimizing cotton-based softness and detail (DTG).

Color Handling and Detail: Vibrancy, Gradients, and Printing Limits

Color handling is a key differentiator in DTF printing and DTG printing. DTF can deliver bold, saturated colors and solid white areas on dark fabrics, thanks to the transferable layer and strong adhesion. Its color management capabilities make it a reliable option for designs with vivid brand colors and crisp edges, even across poly blends. For teams chasing reliable coverage on varied textiles, DTF printing offers a robust pathway to eye-catching graphics.

DTG excels at intricate gradients and subtle color transitions on light fabrics, and its direct application can yield a dreamy, painterly quality when executed well. The soft hand experience on cotton-visible surfaces is a hallmark of DTG, though achieving flawless gradients often requires careful pretreatment and precise white underbase management. Modern DTF workflows have narrowed gaps in color reproduction, but designers still weigh whether ultra-smooth gradients or bold solids are the priority for a given collection.

Cost and Efficiency: Cost Comparison DTF vs DTG for Small Runs

Cost efficiency is a practical driver in choosing between DTF printing and DTG printing for small runs. DTF tends to offer cost advantages in short, full-color runs because it reduces the complexity of color management on the garment itself and can work across a wider range of fabrics without extensive pretreatment. For shops aiming to minimize materials and process variability, DTF’s transfer-based approach can streamline production and reduce waste, which is a meaningful factor in cost-conscious operations.

DTG can present higher upfront and ongoing costs due to printer hardware, maintenance, and pretreatment consumables, though its per-unit cost can become competitive for large cotton-centric orders. Dark fabrics, complex color changes, and frequent material switches can raise the cost and setup time in DTG workflows. When evaluating the economics, brands often perform a cost comparison DTF vs DTG that weighs not only unit price but also setup time, waste, and the flexibility to switch fabrics or designs mid-run.

Durability, Hand Feel, and Wash Performance

Durability and wash performance are crucial in judging long-term value. DTF prints tend to resist cracking and fading when the transfer is properly adhered and edge sealing is maintained, thanks to the ink being sealed into the fabric during the heat-transfer step. The resulting finish is typically durable across a variety of fabrics, even after repeated wash cycles, which is a strong selling point for color-rich designs intended for all-weather wear.

DTG prints can be exceptionally durable on suitable fabrics, especially with correct pretreatment and topcoats, but can be more sensitive to washing conditions if care guidelines aren’t followed. On lighter fabrics, DTG often delivers a soft, almost paint-like hand that customers associate with premium feel, while on dark fabrics, success hinges on a robust white underbase and proper finishing. Across both methods, achieving dependable wash performance depends on preparation, curing, and post-print finishing practices that preserve print integrity over time.

Frequently Asked Questions

DTF printing vs DTG: what’s the difference in t-shirt printing methods?

DTF printing uses a PET film that is printed, coated with bonding powder, and then heat-transferred to the fabric, while DTG printing applies water-based inks directly onto the garment. DTF offers strong color on a wide range of fabrics, whereas DTG shines on cotton-rich fabrics with a soft hand feel. Choose based on fabric compatibility and the desired finish.

How does direct-to-film vs direct-to-garment affect color vibrancy and durability?

Direct-to-film (DTF) generally delivers bold, saturated colors and good white underbase results across many fabrics, with durability aided by the transfer process. Direct-to-garment (DTG) provides excellent color depth on light fabrics and a soft hand, but may require careful pretreatment for durability on dark garments. Proper finishing and sealing are key for both methods.

In a cost comparison DTF vs DTG, which is more cost-effective for small runs?

DTF tends to be more cost-effective for small runs due to simpler setup, fewer pretreatment steps, and broader fabric compatibility. DTG can incur higher upfront costs for printers, maintenance, and pretreatment but may be economical for large cotton-centric orders. Weigh upfront costs against per-unit costs, setup time, and waste.

Which t-shirt printing methods handle complex gradients or photography better: DTF printing or DTG printing?

DTG has a long-standing strength with complex gradients and photographic imagery on light fabrics, delivering smooth color transitions. Modern DTF workflows have closed many gaps and can also reproduce high-detail artwork across fabrics. For very detailed art on dark shirts, both methods can work with the right settings.

What should I consider about fabric compatibility and hand feel when choosing DTF vs DTG?

DTF printing is highly versatile across cotton, polyester, blends, and tricky fabrics, with robust color reproduction. DTG excels on 100% cotton or high-cotton blends and is renowned for a softer hand on light garments. Hand feel and fabric choice should guide the final method based on desired customer experience.

When is a hybrid approach of DTF vs DTG recommended for a brand?

A hybrid approach—DTF for some lines and DTG for others—often yields the best balance of quality, efficiency, and profitability. Use DTF for mixed runs and varied fabrics, and DTG for cotton-centric lines with a premium hand feel. This strategy aligns production with design requirements, order sizes, and business goals.

| Aspect | DTF | DTG |

|---|---|---|

| Process overview | Ink on film; transfer to fabric via heat and pressure; the garment receives a transfer rather than a direct print. | Direct print onto fabric using water-based inks with print heads; result sits on top of the garment. |

| Fabric compatibility | Broad fabric range: cotton, polyester, blends, some textiles. | Best on cotton-rich fabrics; performance on polyester or blends requires pretreatment and color management. |

| Color vibrancy and coverage | Bold colors; strong white underbase for dark fabrics. | Excellent color depth on light fabrics; gradients and detailed imagery. |

| Softness/hand feel | Print may feel firmer due to transfer coating; finishes can feel substantial. | Soft hand feel; ink sits on surface with minimal texture. |

| Durability and wash | Ink embedded via heat transfer; strong wash resistance when properly applied. | Very durable on suitable fabrics but sensitive to washing if pretreatment isn’t proper. |

| Setup and turnaround | Faster setup for mixed runs; less pretreatment per garment. | Efficient for high-volume cotton; pretreatment and color changes can slow setup. |

| Cost | Lower per-unit cost for small runs and full-color designs; simpler color management. | Higher upfront costs; cost per unit improves with large cotton runs but increases with dark fabrics and complex pretreatment. |

| Sustainability and waste | Film and powder waste considerations; proper recycling important. | Ink usage and pretreatment chemicals require careful handling and disposal. |

| When to use (guidance) | Ideal for short to mid-size runs on mixed fabrics; versatile. | Ideal for cotton garments with soft hand and detailed photography on light backgrounds. |

| Practical testing and metrics | Pilot with various fabrics; track cost per unit, turnaround, durability. | Pilot with comparatives; track ink usage, wash performance, color accuracy. |

Summary

DTF vs DTG presents a nuanced choice for brands, as each method offers distinct strengths across fabric compatibility, color, and finish. DTF delivers versatile performance across a wide range of fabrics, bold color reproduction, and strong durability in many conditions, with a streamlined setup that suits mixed-run production. DTG excels in offering a soft hand feel and high-detail imagery on cotton-rich garments, especially on light shirts, though it can require pretreatment and careful color management. For many shops, a hybrid approach—using DTF for mixed fabrics and DTG for cotton-heavy lines—provides the best balance of efficiency, quality, and scalability. Ultimately, the right choice depends on your design requirements, target market, production capacity, and cost considerations; consistent color management and proper finishing are key to maximizing the value of either method.