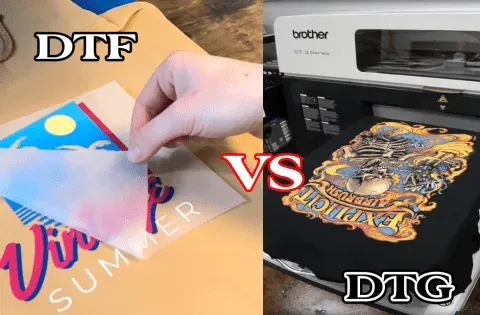

When evaluating garment printing techniques, the debate of DTF vs. DTG often arises, highlighting the distinct advantages of Direct to Film printing and Direct to Garment printing. Each method presents its own set of benefits and challenges, particularly impacting print quality comparison and material versatility. DTF printing benefits from its ability to transfer designs onto various fabrics, making it a favored choice for multi-material applications. In contrast, DTG excels with its high-resolution prints and vibrant colors, especially on cotton substrates. This overview aims to dissect these two methods, helping you make an informed decision that aligns with your printing needs.

In the world of fabric design, the discussion around DTF and DTG emerges as a pivotal topic, with various terms used to describe these innovative techniques. Also known as Direct to Film and Direct to Garment methods, both processes leverage advanced printing technologies that significantly impact the quality and efficiency of custom designs. As we explore these garment printing strategies, it becomes clear that each technique has its own niche and suitability depending on the material and desired outcome. From understanding how each method captures detail and color to examining their practical applications, this analysis will shed light on which approach best meets your creative aspirations.

Comparing DTF and DTG: Key Differences Explained

In the realm of garment printing, Direct to Film (DTF) and Direct to Garment (DTG) represent two innovative methods that cater to varying needs and preferences. DTF operates by printing designs onto a specialized film, which is later applied to various fabrics under heat, making it a versatile option for multiple materials including polyester and blends. In contrast, DTG prints directly onto garments using advanced inkjet technology. This method specializes in creating high-resolution images and is particularly effective on cotton, showcasing intricate designs with a wide range of colors.

Understanding the key differences between DTF and DTG is essential for businesses looking to capitalize on garment printing. DTF may offer better flexibility and quicker application times, especially for bulk runs, while DTG shines in delivering crisp detail and vivid prints for single or small runs. Awareness of these differences enables designers and businesses to make informed choices that align with their product goals.

Print Quality: How DTF and DTG Measure Up

When assessing print quality, the purported strengths of DTG and DTF come into sharp focus. DTG is renowned for its ability to produce extraordinary detail in prints. The direct application of ink onto fabric allows for various gradients and hues to be effortlessly rendered, making it ideal for designs that require high levels of intricacy. This precision makes DTG the preferred choice for artwork that leans towards photorealism or contains complex shading.

While DTF may not yet reach the same pinnacle of detailed gradient work as DTG, it compensates with a robust print quality that can adhere to numerous fabric types efficiently. The technological advancements in DTF are continually refining its resolution and color vibrancy, creating a competitive atmosphere. As DTF printers evolve, they increasingly meet the high-quality expectations typically associated with DTG, appealing to brands looking for both versatility and a substantial visual impact.

Speed of Production: DTF vs. DTG

Production speed is a vital consideration in garment printing, especially for businesses that prioritize quick turnaround times. DTF impresses with its efficiency primarily due to its unique process. With the ability to create transfers in advance and apply them en masse, DTF allows for rapid production cycles, making it a favorable option for large orders and promotional runs. Brands seeking high output with minimal delays often gravitate towards DTF for its timely deliverables.

Conversely, DTG can fall behind in terms of speed because each garment requires individual setup and pretreatment to ensure proper ink adhesion. This meticulous approach can lead to longer wait times, making DTG less suited for projects that demand speed. However, for smaller batches or custom pieces, the detailed craftsmanship of DTG can justify the longer production time, as it provides luxurious prints that stand out in quality.

Cost-Effectiveness in Garment Printing

The economic factors of garment printing techniques play a crucial role in determining which method to utilize. For small batch runs, DTG is often more economical due to the lower setup costs associated with individualized prints. This makes it an attractive option for small businesses or events seeking unique, customized attire without overextending their budget.

In contrast, DTF tends to be the more cost-effective choice for larger runs, as the pre-printed films can be reused, significantly reducing the cost per item produced. This is particularly beneficial for brands needing to produce promotional merchandise or uniform garments at scale, where efficiency translates directly into financial savings. As such, the choice between DTG and DTF can greatly depend on the anticipated order size and budget constraints.

Recent Advancements in DTF and DTG Technologies

The landscape of garment printing is in constant flux, with both DTF and DTG technologies witnessing rapid advancements. Manufacturers are focused on enhancing ink formulations and printer efficiencies, striving to push the boundaries of print quality, durability, and vibrancy. Recent upgrades in DTF technology have made substantial strides in matching the color accuracy and detail typically associated with DTG, offering exciting new possibilities for businesses.

Moreover, the shift in consumer demand towards efficient and versatile printing techniques has led to increased adoption of DTF within the industry. As businesses look to fulfill orders for custom merchandise and unique promotional items quickly, ongoing innovations in both methods are expected to cater effectively to market needs, ensuring they stay competitive and relevant.

Choosing Between DTF and DTG: Insights for Your Printing Needs

Deciding between DTF and DTG printing is a nuanced choice that hinges on specific project requirements, fabric types, and aesthetic goals. For individuals or businesses wanting intricate designs on cotton garments that require rich color representation, DTG might be the preferred choice due to its print fidelity and depth. This technique excels in ensuring that fine details remain intact, making it ideal for prints that are meant to impress.

On the other hand, DTF offers unparalleled versatility and efficiency, appealing to those who need quick production times across various fabric types. This flexibility allows brands to explore a wider array of product offerings without being limited by fabric characteristics. Selecting the appropriate method ultimately rests on considerations of desired print quality, production speed, and economic impact, allowing brands to tailor their garment printing strategies according to capable advantages in both technologies.

Frequently Asked Questions

What is the difference between DTF and DTG printing in terms of print quality?

DTF (Direct to Film) and DTG (Direct to Garment) printing differ significantly in print quality. DTG is renowned for producing vibrant, high-resolution prints, particularly suitable for cotton fabrics, making it ideal for intricate designs and gradients. Conversely, while DTF offers good color adherence on various fabrics, it may not replicate the same level of detail in gradient designs as DTG, although technology improvements are narrowing this gap.

Which garment printing technique is more cost-effective for large production runs, DTF or DTG?

DTF printing is generally more cost-effective for large production runs. This is because film transfers can be reused multiple times, significantly reducing the cost per print. In contrast, DTG can be more economical for smaller batches or individual prints due to its setup costs being spread across fewer items.

Can you explain the processes involved in DTF vs. DTG printing?

The process for DTF (Direct to Film) involves printing a design onto a special film which is then heat-transferred to the fabric, allowing for pre-printed designs that can be stored. DTG (Direct to Garment) printing, however, requires direct printing onto the garment, with a pretreatment step necessary to ensure ink adherence, potentially slowing the production process.

In terms of production speed, how do DTF and DTG compare?

DTF printing is typically faster for larger orders, as multiple designs can be printed and applied in one step, leading to reduced production times. In contrast, DTG printing can be slower, often requiring individual preparations and pretreatments for each garment, which complicates quick turnarounds.

What are some advantages of DTF printing over DTG in garment printing?

DTF printing offers several advantages, including its versatility to work with various fabrics beyond just cotton, faster production speeds for bulk prints, and the ability to pre-print designs for later application. These factors make DTF particularly appealing for custom merchandise and promotional items.

How do recent advancements in technology affect DTF compared to DTG in garment printing?

Recent advancements in printing technology are enhancing the capabilities of DTF printing, improving its detail and color accuracy to compete with DTG. As manufacturers continue to innovate, DTF is gaining popularity due to its efficiency and versatility, positioning it as a formidable option alongside the traditional DTG method.

| Key Aspects | DTG (Direct to Garment) | DTF (Direct to Film) |

|---|---|---|

| Print Quality | Superior for intricate designs with gradients and photographic images, especially on cotton. | Vibrant prints for various fabrics, but detail in gradients may be less than DTG. |

| Process and Equipment | Prints directly on the garment, requires pretreatment for adhesion. | Pre-prints transfers that can be stored and heat-pressed onto fabrics. |

| Production Speed | Slower due to individual garment setups and pretreatment. | Faster for large orders, printing multiple designs and applying them in one step. |

| Cost-Effectiveness | Economical for small runs or custom prints due to higher setup costs per item. | More cost-effective for large runs with reusable film transfers lowering costs. |

| Recent Developments | Maintains top position in quality, especially for cotton. | Rapid advancements are closing the quality gap with DTG. |

Summary

In the world of garment printing, understanding DTF vs. DTG is essential for making informed decisions based on specific project requirements. DTG offers unparalleled quality for intricate designs on cotton, making it perfect for artistic prints that demand high fidelity. Conversely, DTF has emerged as a versatile and efficient option, well-suited for diverse materials and higher production speeds, especially advantageous for businesses with large orders. The choice between DTF and DTG ultimately hinges on factors such as production volume, print detail, and material compatibility, as both technologies continue to innovate and enhance the garment printing landscape.